Method for bonding rubber plate by using chloroprene rubber adhesive

A technology using neoprene and neoprene, applied in the direction of adhesives, bonding methods, etc., can solve the problems of poor sealing, dimensional changes, and easy dislocation of holes, so as to reduce a lot of rework and repair work, save money Manufacturing cost and time cost, the effect of facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Bonding Rubber Sheets Using Neoprene Adhesive

[0038] Include the following steps:

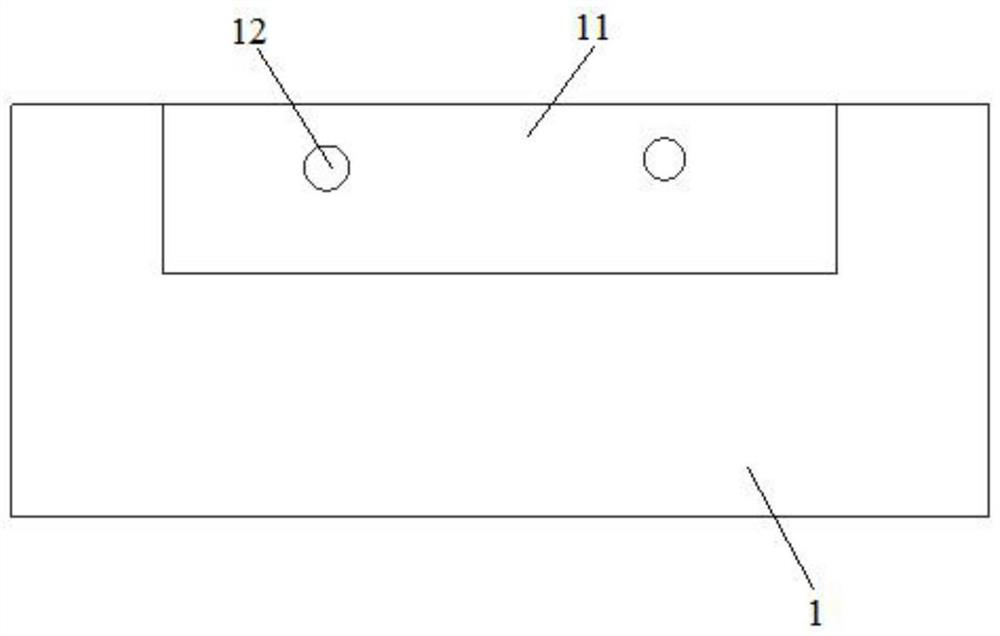

[0039] Step 1. Prepare the panel 1 to be bonded, and determine the first adhesive area 11 on the panel 1, wherein the panel 1 is provided with a hole 12, and the hole 12 is located in the first adhesive area 11 Inside; the panel 1 is a metal plate, such as figure 1 shown.

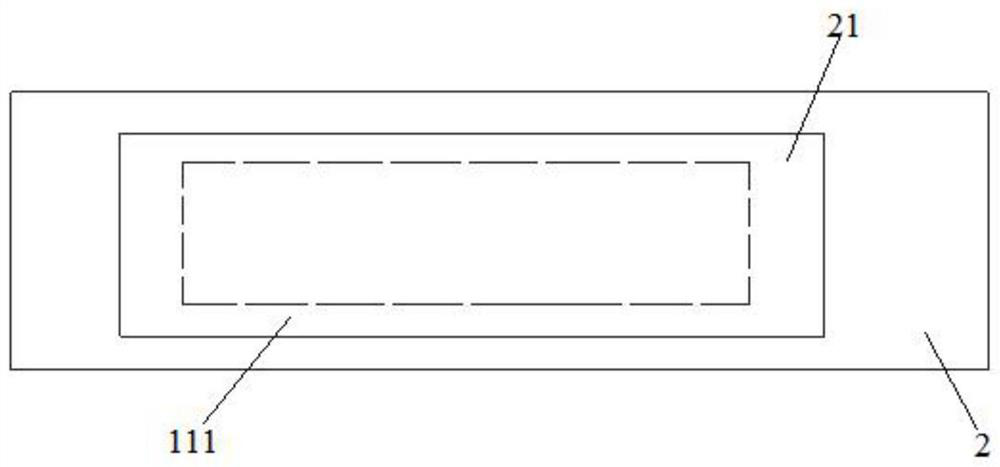

[0040] Step 2, preparing the rubber sheet 2, confirming the second adhesive area 21 on the rubber sheet 2, wherein the second adhesive area 21 can completely cover the first adhesive area 11 and has a margin area 111, wherein , the shortest width of the margin area 111 is 20mm, such as figure 2 shown.

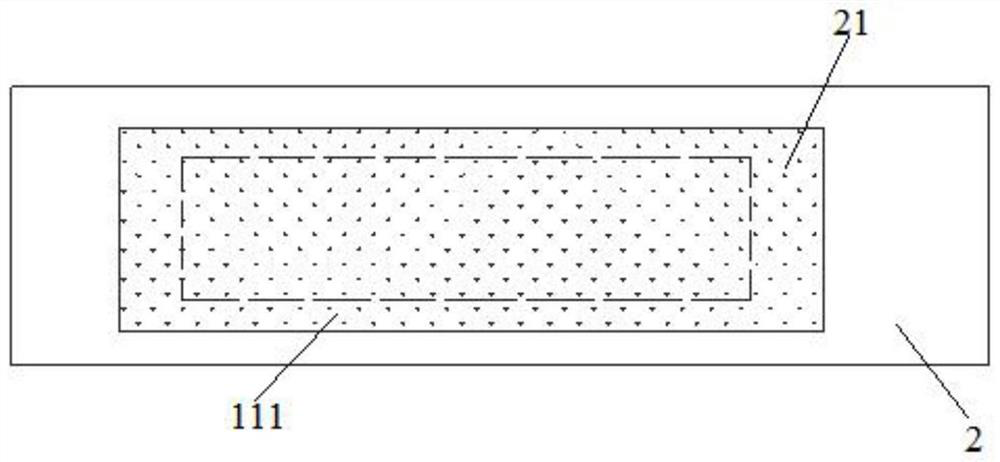

[0041] Step 3. Perform surface cleaning treatment on the second adhesive area 21, evenly paint the first neoprene adhesive in the second adhesive area 21, and place the second adhesive area 21 facing up for 28 hours, Until the first neoprene adhesive on the second adhesive area 21 stops natural shrinkage, as ...

Embodiment 2

[0046] Bonding Rubber Sheets Using Neoprene Adhesive

[0047] Include the following steps:

[0048] Step 1. Prepare the panel 1 to be bonded, and determine the first adhesive area 11 on the panel 1, wherein the panel 1 is provided with a hole 12, and the hole 12 is located in the first adhesive area 11 Inside; the panel 1 is a metal plate.

[0049] Step 2, preparing the rubber sheet 2, confirming the second adhesive area 21 on the rubber sheet 2, wherein the second adhesive area 21 can completely cover the first adhesive area 11 and has a margin area 111, wherein , the shortest width of the margin area 111 is 30mm.

[0050] Step 3. Perform surface cleaning treatment on the second adhesive area 21, evenly paint the first neoprene adhesive in the second adhesive area 21, and place the second adhesive area 21 facing up for 24 hours, Until the first neoprene adhesive on the second adhesive area 21 stops naturally shrinking.

[0051] Step 4: Clean the surface of the first adhes...

Embodiment 3

[0055] Bonding Rubber Sheets Using Neoprene Adhesive

[0056] Include the following steps:

[0057] Step 1. Prepare the panel 1 to be bonded, and determine the first adhesive area 11 on the panel 1, wherein the panel 1 is provided with a hole 12, and the hole 12 is located in the first adhesive area 11 Inside; the panel 1 is a metal plate.

[0058] Step 2, preparing the rubber sheet 2, confirming the second adhesive area 21 on the rubber sheet 2, wherein the second adhesive area 21 can completely cover the first adhesive area 11 and has a margin area 111, wherein , the shortest width of the margin area 111 is 25mm.

[0059] Step 3. Perform surface cleaning treatment on the second adhesive area 21, evenly paint the first neoprene adhesive in the second adhesive area 21, and place the second adhesive area 21 facing up for 18 hours, Until the first neoprene adhesive on the second adhesive area 21 stops naturally shrinking.

[0060] Step 4: Clean the surface of the second adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com