Textile cloth wetting device for spinning

A textile cloth, wetting technology, applied in the field of textile cloth wetting devices for textiles, can solve the problems of water pollution, influence processing, dust entry, etc., and achieve the effect of improving product quality and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

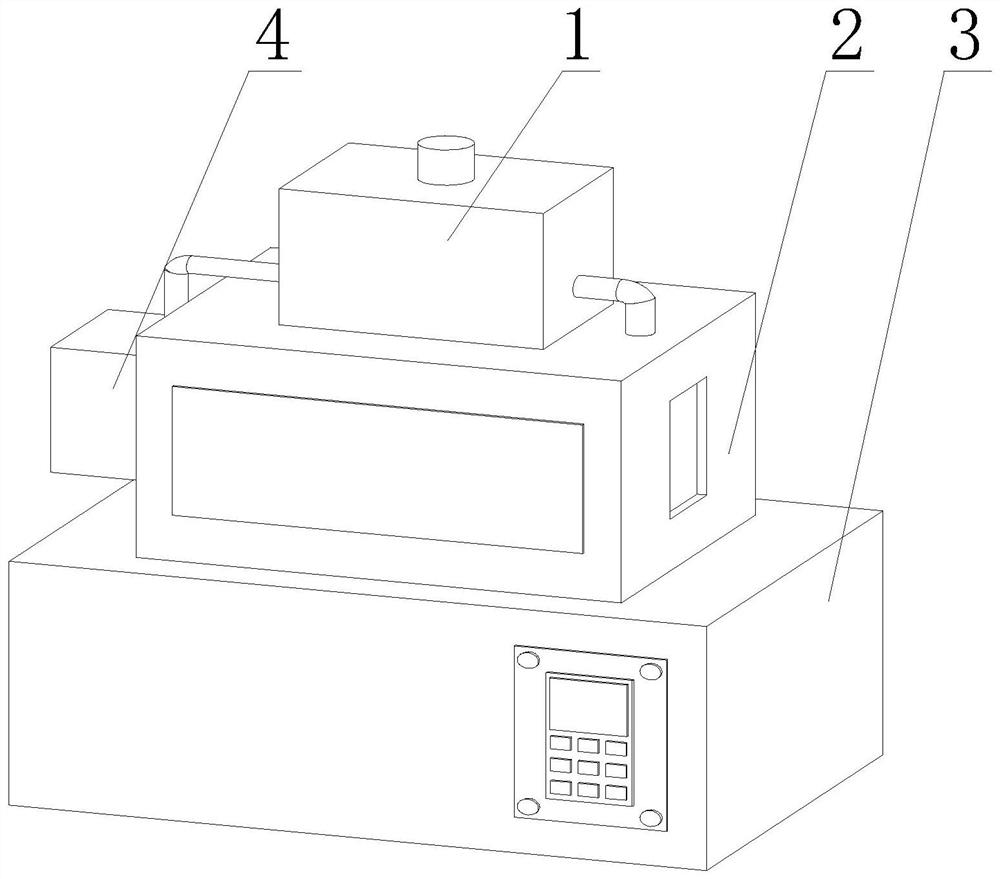

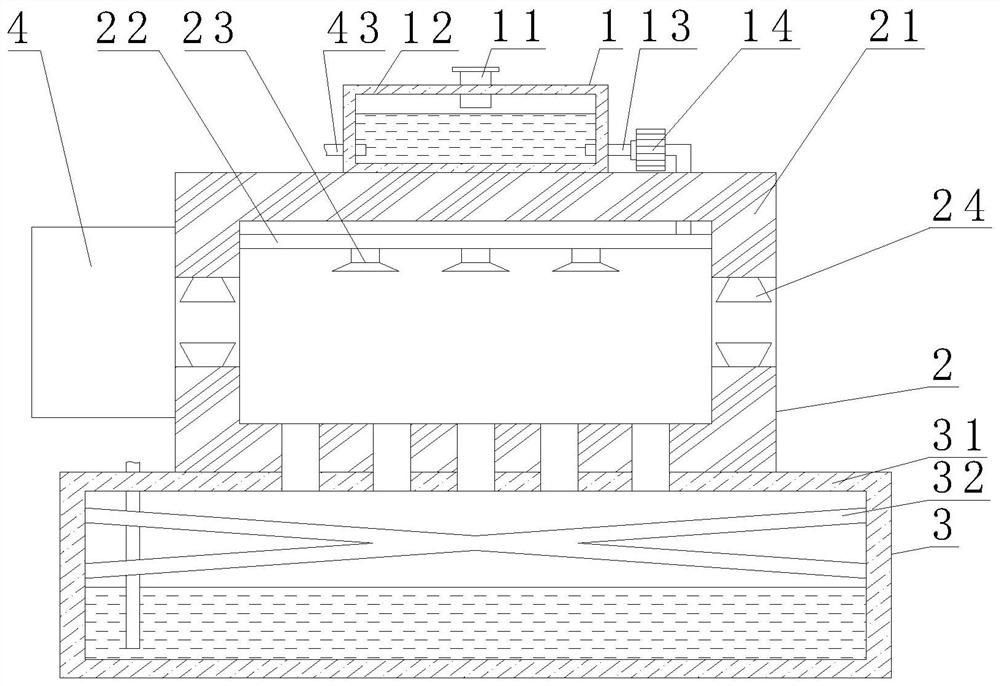

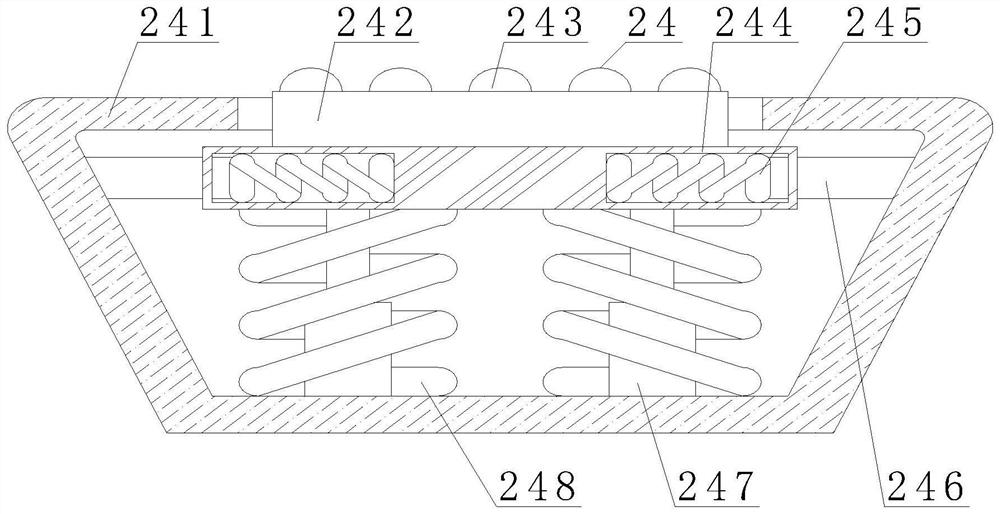

[0040] Such as Figure 1-6As shown, the present invention provides a wetting device for weaving textile fabrics, comprising a wetting device 2, a water supply mechanism 1 is provided on the top of the wetting device 2, a water storage mechanism 3 is provided at the bottom of the wetting device 2, and the left side of the wetting device 2 A cleaning mechanism 4 is provided, the wetting device 2 includes a cloth guide mechanism 24, and the cloth guide mechanism 24 includes a cloth guide housing 241, the inner wall of the cloth guide housing 241 is fixedly connected with a telescopic rod 247, and the inner wall of the cloth guide housing 241 is located at the The outside is fixedly connected with the No. 2 spring 248, and the other end of the telescopic rod 247 is fixedly connected with the lifting plate 244. The inside of the lifting plate 244 is provided with a placement groove, and the inner wall side of the placement groove is fixedly connected with a No. 2 spring 245, and the...

Embodiment 2

[0043] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the cleaning mechanism 4 includes a cleaning shell 41, the interior of the cleaning shell 41 is provided with a mounting groove, and the inner wall of the mounting groove is provided with a No. 3 spring 42, The surface of No. 3 spring 42 is fixedly connected with connecting plate 49, and the surface of connecting plate 49 is fixedly connected with motor 50, and the output end of motor 50 is fixedly connected with threaded rod 51, and the surface of threaded rod 51 is threadedly connected with supporting plate 52, supporting plate The surface of 52 is fixedly connected with hairbrush 53, the surface of support plate 52 is overlapped with flowing ball 48, the inner wall of cleaning shell 41 is fixedly connected with fixed shell 45, the surface of fixed shell 45 is fixedly connected with cleaning cloth 47, and the surface of fixed shell 45 is fixedly ...

Embodiment 3

[0046] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the water supply mechanism 1 includes a water inlet mechanism 11, and the water inlet mechanism 11 includes a water inlet pipe 114, and the inner wall of the water inlet pipe 114 is fixedly connected with a filter plate 117, the inner wall of the water inlet pipe 114 is fixedly connected with an elastic pad 115 above the filter plate 117; A sealing cover 111 is overlapped, and the top of the rotating rod 118 extends to the top of the sealing cover 111 and is fixedly connected with a top plate 112 , and the bottom of the top plate 112 is fixedly connected with an elastic block 113 .

[0047] In this embodiment, during the sealing process, the top plate 112 is in a vertical state at this time. Since the inside of the sealing cover 111 is provided with an opening, the sealing cover 111 is placed above the water inlet pipe 114, and the opening is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com