Pet slice with ductility

A ductility and slicing technology, applied in the direction of testing the ductility and strength properties of materials, and using stable tension/pressure to test the strength of materials. Inconvenient slicing and other problems, to achieve the effect of reducing equipment use and sample anomalies, intuitive and convenient test data collection, and convenient classification and pick-and-place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

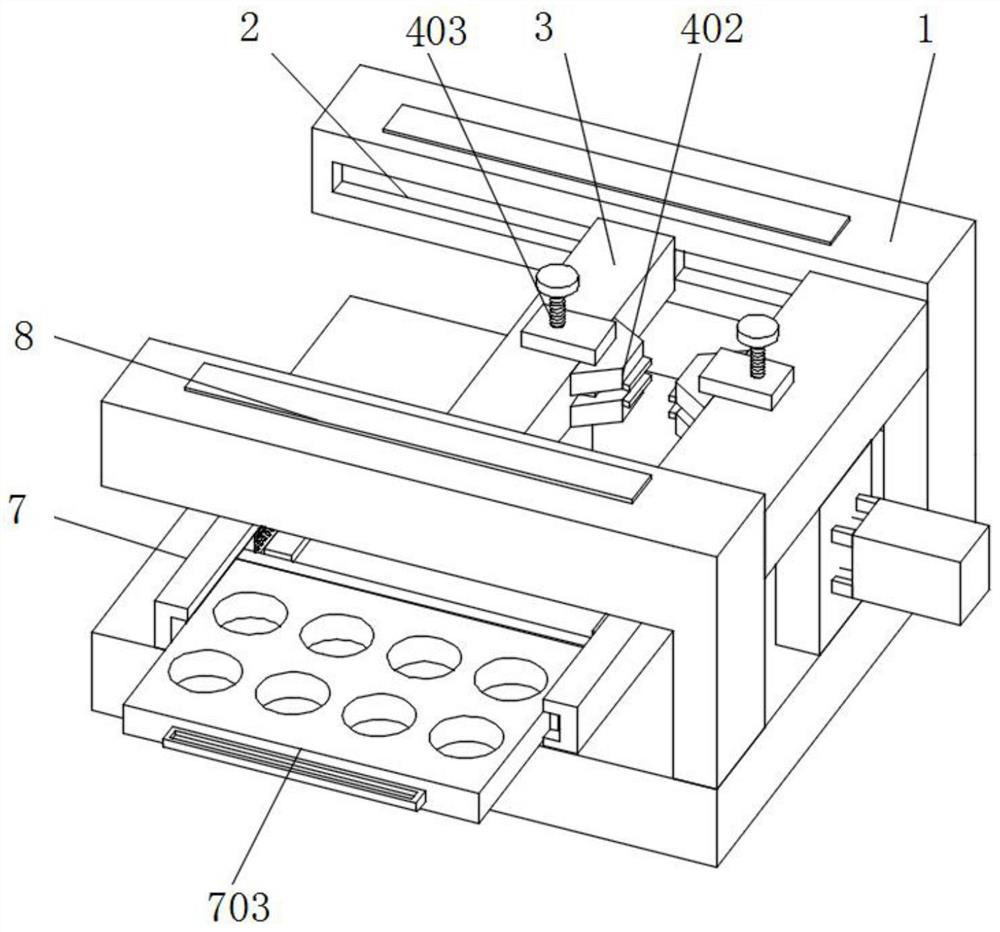

[0022] see Figure 1-2 As shown, a pet slice with ductility includes a main body 1, a chute 2, a sliding frame 3, a clamping mechanism 4, a connecting plate 5, a transmission rod 6, a sliding mechanism 7 and a scale 8, and the inner side of the main body 1 is provided with chute 2, and the inside of the chute 2 is connected with a sliding frame 3, and the outside of the sliding frame 3 is provided with a gripping mechanism 4, and the bottom of the sliding frame 3 is provided with a connecting plate 5, and the inside of the connecting plate 5 is penetrated by a transmission rod 6;

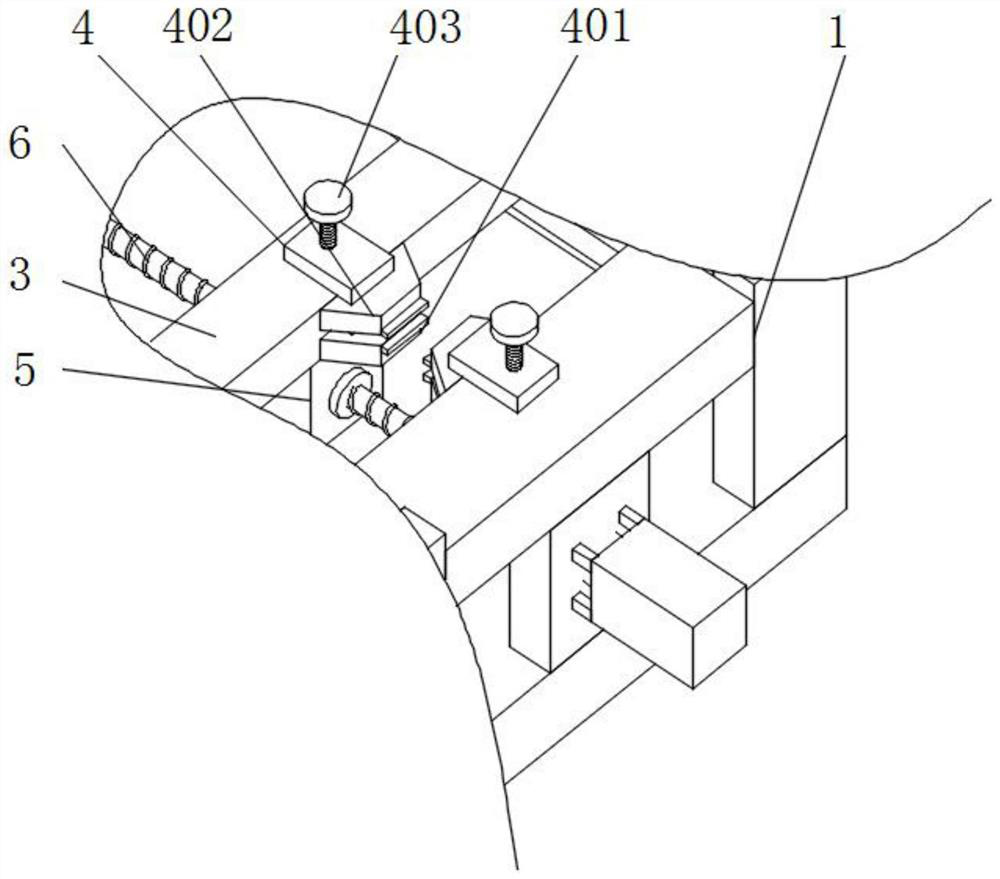

[0023] The clamping mechanism 4 includes a lower biting block 401, an upper biting block 402 and a screw rod 403, an upper biting block 402 is arranged above the lower biting block 401, and a screw rod 403 runs through the inside of the upper biting block 402;

[0024] The upper bite block 402 forms a lift structure between the screw rod 403 and the lower bite block 401, and the upper bite block 40...

Embodiment 2

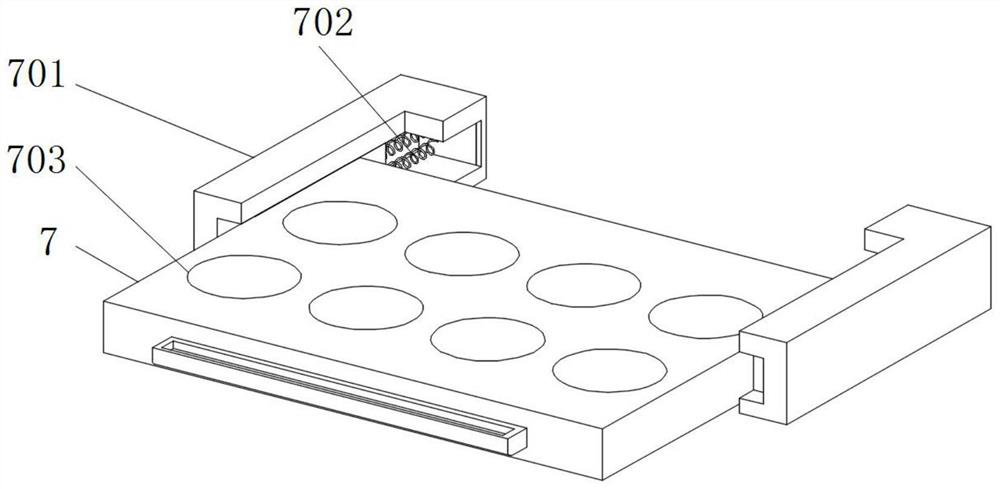

[0027] see figure 1 with image 3 As shown, a pet slice with ductility, a sliding mechanism 7 is arranged under the chute 2, and a scale 8 is arranged on the top of the main body 1;

[0028] The sliding mechanism 7 includes a slide rail 701, a spring 702 and a collection groove 703, the inside of the slide rail 701 is provided with a spring 702, and the end of the spring 702 is connected to the collection groove 703;

[0029] The collection tank 703 forms a lifting structure through the spring 702 and the slide rail 701, and the slide rail 701 is arranged symmetrically with respect to the central axis of the collection tank 703. Slide and pull out along the slide rail 701.

[0030] Working principle: First, the slice is clamped and fixed by the clamping mechanism 4, the slice is placed between the upper bite block 402 and the lower bite block 401, and the position of the upper bite block 402 is adjusted by rotating the top screw 403, which can The slices are clamped and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com