Combined selenium drum capable of circularly replacing powder box

A combined type and powder box technology, which is applied to the electrical recording process using the charge pattern, the equipment of the electric recording process using the charge pattern, and the electrography, etc., can solve the problem of high replacement and maintenance costs of the toner cartridge, and reduce maintenance costs. The effect of long service life and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

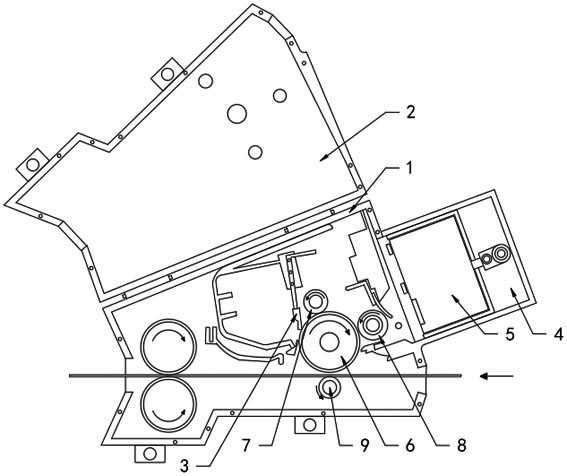

[0032] refer to Figure 1-5 , a combined toner cartridge capable of cyclically replacing the toner cartridge, comprising a toner bin 4, a photosensitive drum 6, a charging roller 7, a developing roller 8, and a transfer roller 9, and also includes:

[0033] Housing 1, the housing 1 has a box-shaped structure, one side of the housing 1 is connected with the housing cover 2 through the rotating shaft, and the opening direction of the housing cover 2 is parallel to the axial direction of the charging roller 7, and a lock is installed on the housing cover 2 Tighten the bolts, the shell cover 2 is provided with a gap facing the powder bin 4, a locking bolt is installed on the extension end of the shell cover 2, the shell cover 2 is fixedly connected with the shell 1 through the locking bolts, and the two sides of the shell 1 are provided for The channel for paper conveyance;

[0034] The powder box 5, the powder box 5 is arranged in the powder bin 4, the screw rod 19 parallel to t...

Embodiment 2

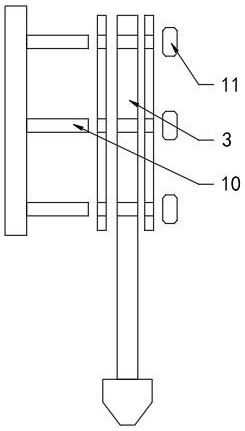

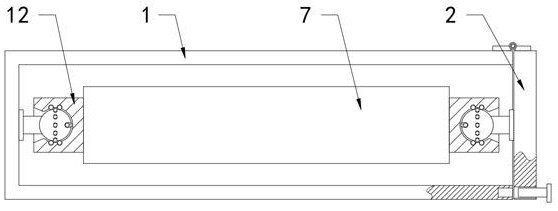

[0038] refer to Figure 1-5, a combined toner cartridge that can be cyclically replaced with a powder cartridge, including a powder bin 4, a photosensitive drum 6, a developing roller 8 and a transfer roller 9, and also includes: a housing 1, the housing 1 is a box-shaped structure, and the housing 1 One side is connected to the case cover 2 through the rotating shaft, and the extension end of the case cover 2 is equipped with locking bolts, and the case cover 2 is fixedly connected with the casing 1 through the locking bolts, and the two sides of the casing 1 are provided with passages for paper transmission , the housing cover 2 is equipped with locking bolts, and the housing cover 2 is provided with a gap facing the powder bin 4; the charging roller 7, the axis extension end of the charging roller 7 faces the direction of the housing cover 2, and the two ends of the charging roller 7 are installed with installation heads 12. There is an installation card slot 15 on one side...

Embodiment 3

[0042] refer to Figure 1-5 , a combined toner cartridge that can be cyclically replaced with a toner cartridge, including a toner bin 4, a photosensitive drum 6, a developing roller 8 and a transfer roller 9, and also includes:

[0043] Housing 1, the housing 1 is a box-shaped structure, one side of the housing 1 is connected to the housing cover 2 through the rotation of the shaft, the housing cover 2 is equipped with locking bolts, the housing cover 2 is provided with a gap facing the powder bin 4, the housing A locking bolt is installed on the extension end of the cover 2, and the cover 2 is fixedly connected with the housing 1 through the locking bolt, and the two sides of the housing 1 are provided with channels for paper transmission;

[0044] The charging roller 7, the axial extension end of the charging roller 7 faces the direction of the shell cover 2, the two ends of the charging roller 7 are installed with the installation head 12, and the side of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com