Casting mold capable of improving casting yield

A technology for casting molds and good product rate, which is applied in the field of casting processing. It can solve the problems of easy formation of pores in castings, inability to discharge gas, and low mold temperature, so as to reduce the probability of pores, amplify vibration, and improve the quality of castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

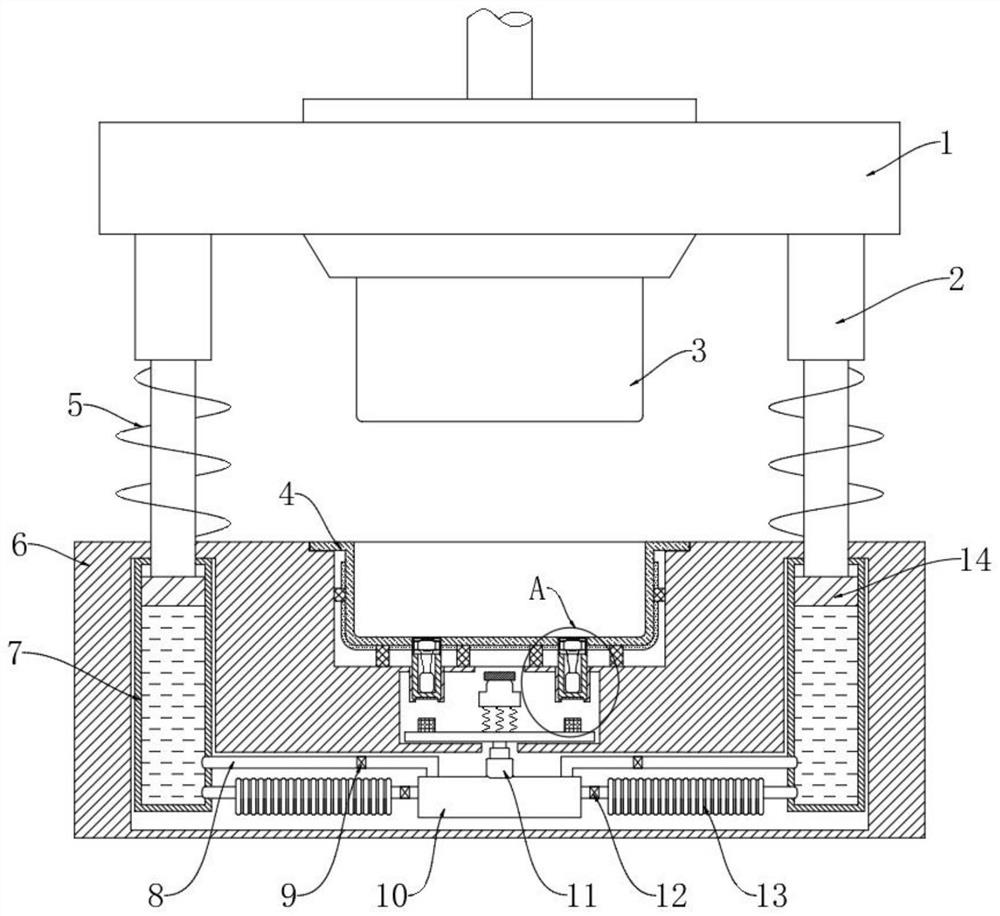

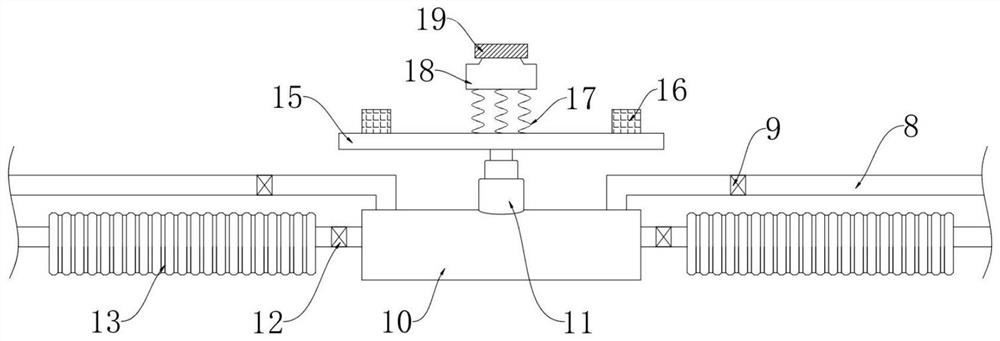

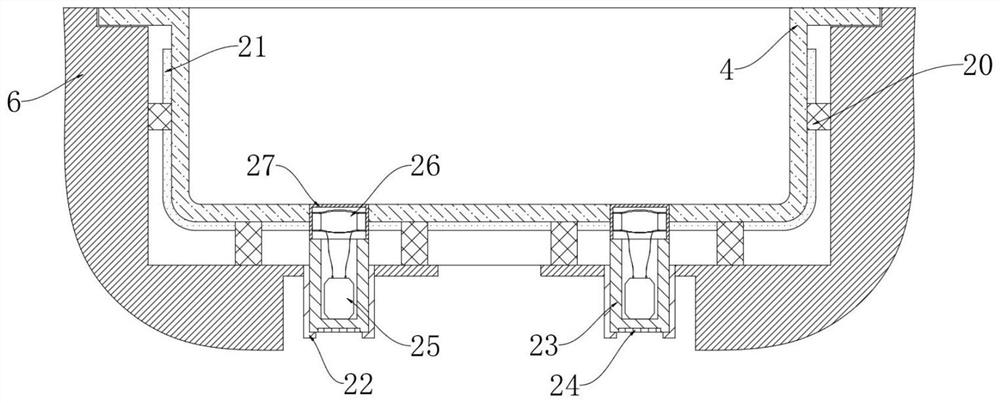

[0025] refer to Figure 1-4 , a casting mold that can improve the yield of castings, including a pressing plate 1 and a base 6, a casting briquetting block 3 is fixedly installed under the pressing plate 1, the mechanism for driving the pressing plate 1 and the casting briquetting block 3 is not shown in the figure, and the base 6 A casting tank body 4 is fixedly installed, and two sealing cylinders 7 are symmetrically arranged in the base 6, and sealing plates 14 are slidably installed in the two sealing cylinders 7, and fixed shafts 2 are fixedly connected to the two sealing plates 14, and two The upper ends of the fixed shafts 2 pass through the top of the corresponding sealing cylinder 7 and are fixedly connected with the lower surface of the pressure plate 1. The outer circumferences of the two fixed shafts 2 are all wound with first springs 5, and the upper ends of the two first springs 5 are connected to the pressure plate. 1 is fixedly connected, the lower ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com