Rapid positioning device for tank welding

A technology for positioning devices and tanks, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as unstable water demand, low production efficiency, and slow positioning speed, and achieve low positioning costs, fast and accurate positioning, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

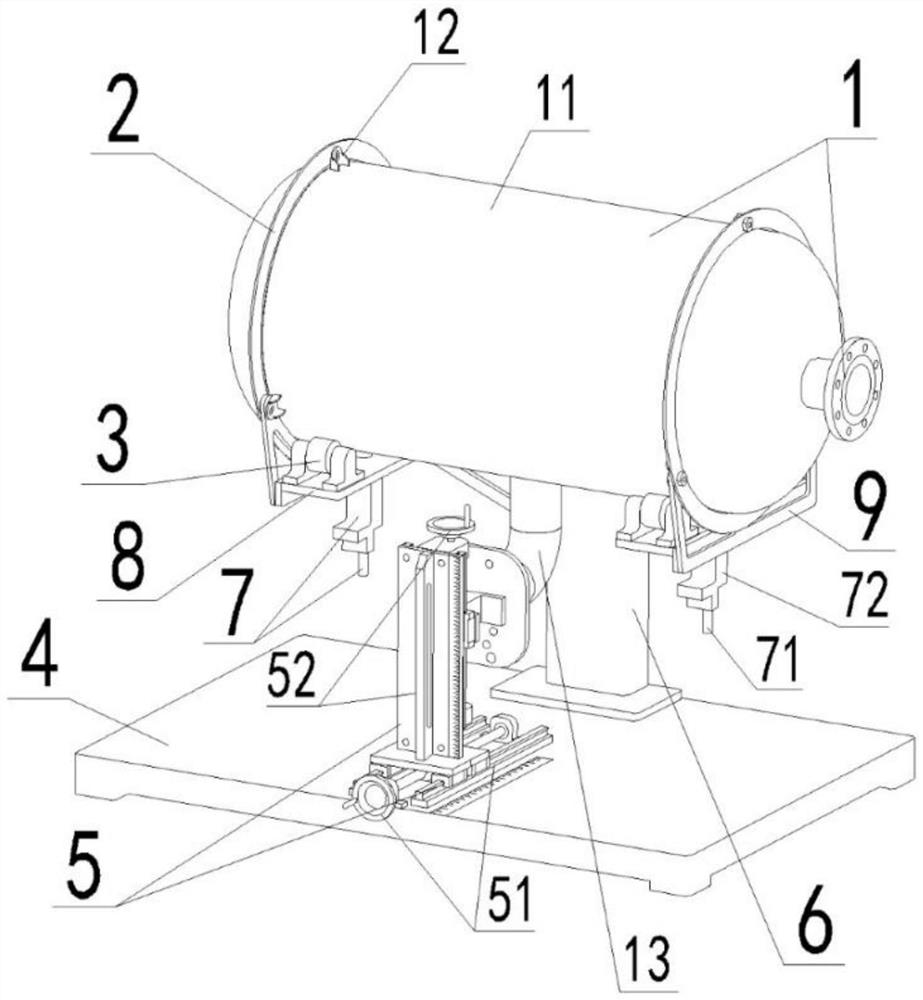

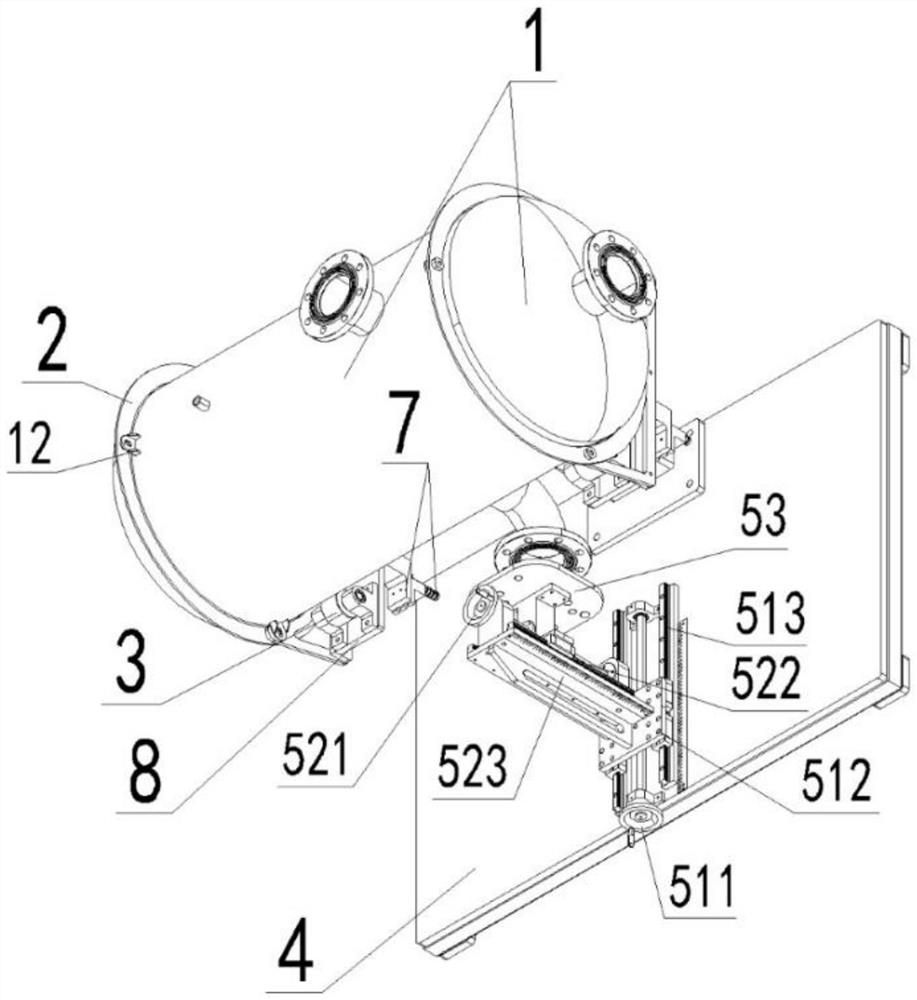

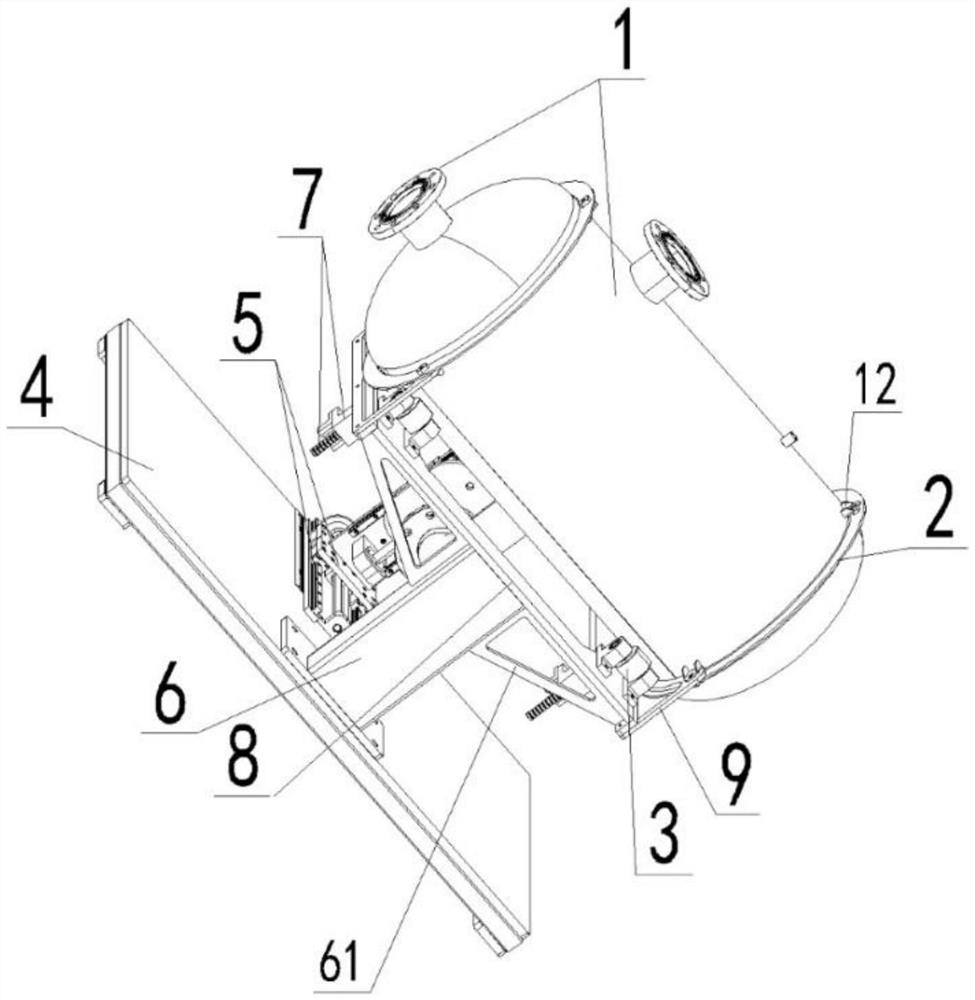

[0050] refer to Figure 1 to Figure 5 , a tank body welding rapid positioning device includes a base 4, and a supporting base 6 arranged on the base 4, a horizontal pallet 8 is arranged on the supporting base 6, and a joist 61 is provided on the lower part of the horizontal pallet 8, and the joist 61 It is in the shape of a right-angled triangle. The upper top surface of the joist 61 is connected to the lower bottom surface of the horizontal pallet 8, and the outer surface of the joist 61 is connected to the outer side of the support seat 6. The joist 61 can make the horizontal pallet 8 and the support seat 6 Good connection stability (such as image 3 and Figure 4 shown), also includes:

[0051] The wheel support assemblies 3 on the left and right sides above the horizontal pallet 8 are arranged. The wheel support assemblies 3 have two groups, and the two groups of wheel support assemblies 3 are symmetrical along the longitudinal vertical center plane of the horizontal pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com