Protective liquid tank structure for resisting underwater explosion high-speed fragments

A technology of underwater explosion and protective liquid, which is applied in the direction of hull bulkhead, hull, ship construction, etc., can solve the problems of limited dissipation and limited liquid tank space, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

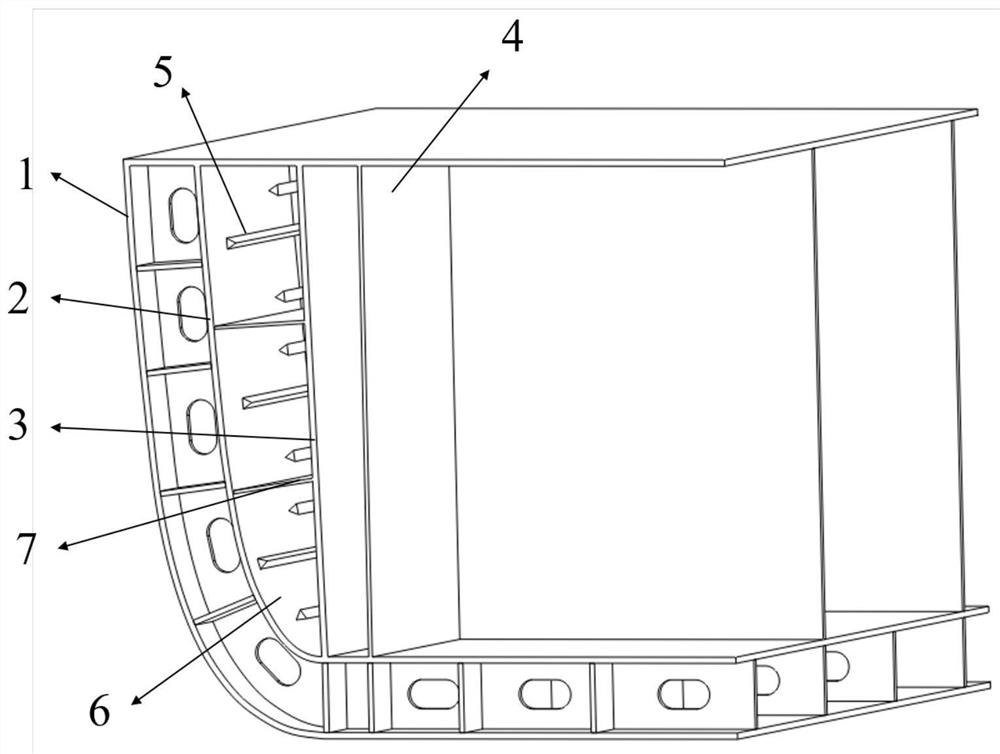

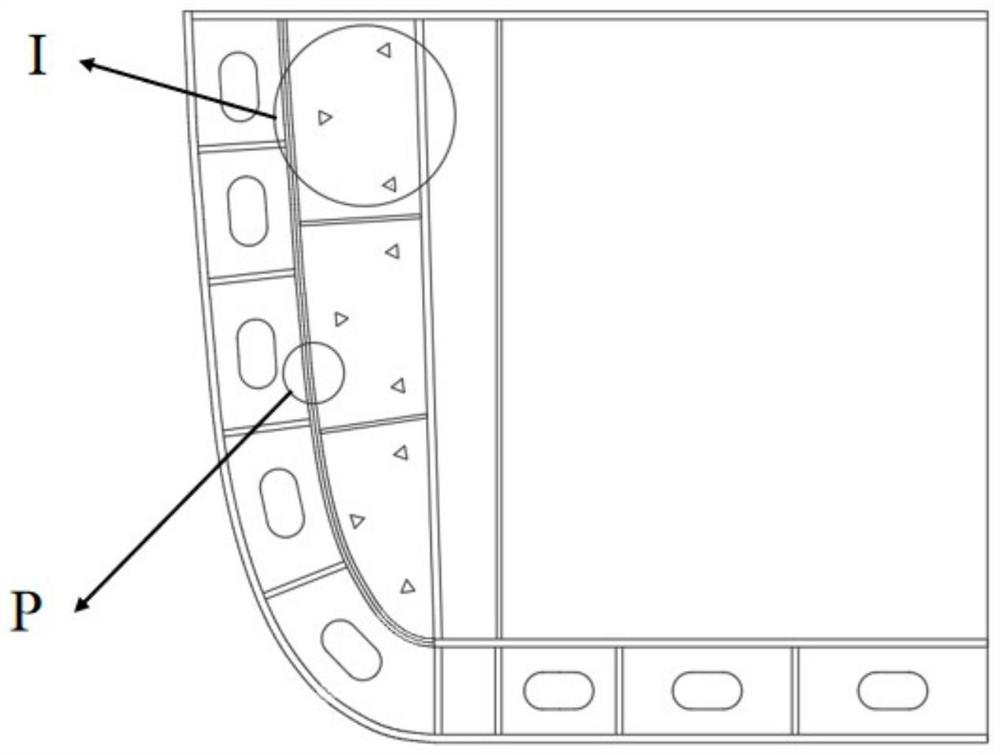

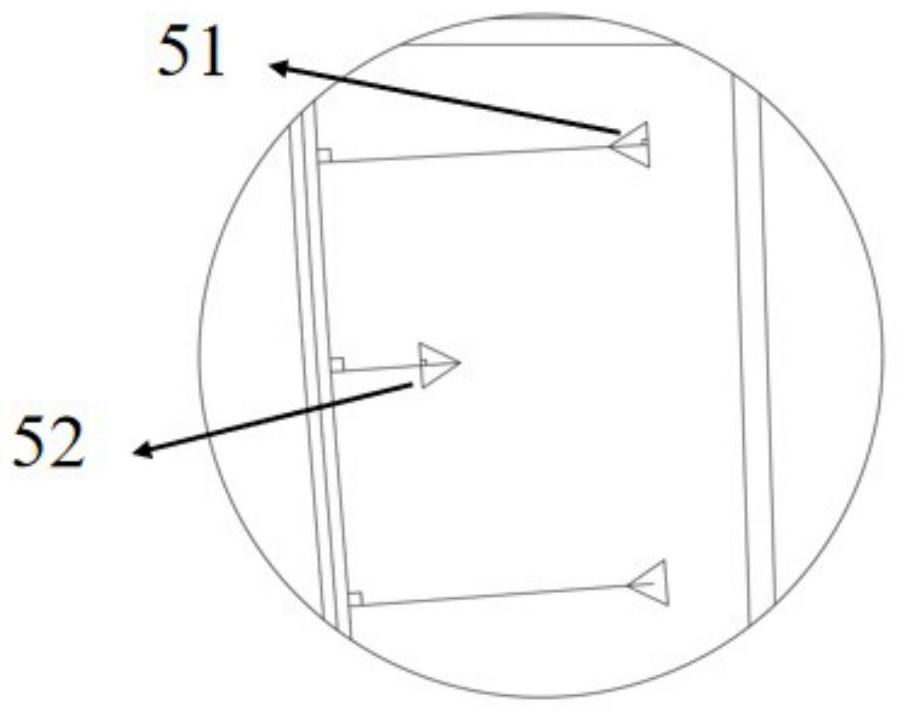

[0028] Specific implementation mode one: combine Figure 1~6 Description of this embodiment, a protective liquid tank structure against high-speed underwater explosion fragments, it includes the liquid tank outer plate 2 and the liquid tank inner plate 3 arranged in sequence from the outside to the inside, wherein the liquid tank inner plate 3, the liquid tank outer plate 2 and the cavity between the plates together form a protective liquid tank, and the cavity is filled with absorption liquid 6, and a number of inner partitions 7 and a number of reinforcing ribs 5 are also arranged in the protective liquid tank, and each inner partition 7 and each reinforcement The ribs 5 are all arranged along the length of the ship, and several inner partitions 7 are arranged sequentially from top to bottom. Several reinforcing ribs 5 and several inner partitions 7 are arranged alternately. The tank inner plate 3 is fixedly connected, and the two ends of each rib 5 are respectively fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com