Aluminum shell conveying device of new energy storage module and preparation method of aluminum shell conveying device

An energy storage module and conveying device technology, applied in the field of mechanical design, can solve the problems of time-consuming and laborious, increase process time and labor cost, etc., and achieve the effects of stable structure, stable labeling on one side, and high degree of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

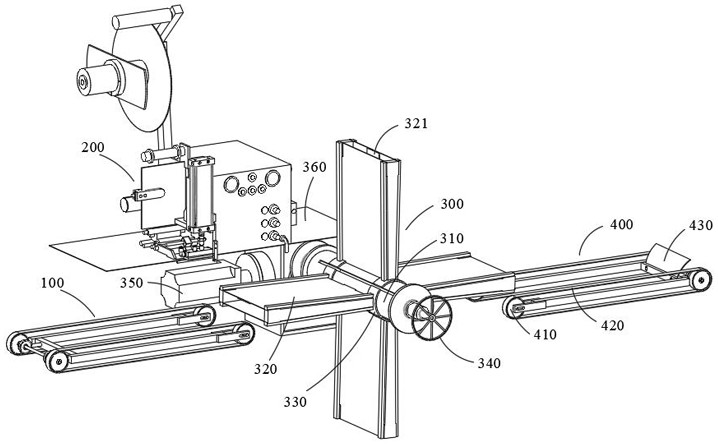

[0035] See Figure 1 to Figure 3 , the present invention provides an aluminum casing conveying device for a new energy storage module, comprising:

[0036] The input part 100, the input part 100 is used for inputting the aluminum plate;

[0037] Labeling unit 200, the labeling unit 200 is used for labeling the aluminum plate input by the input unit 100;

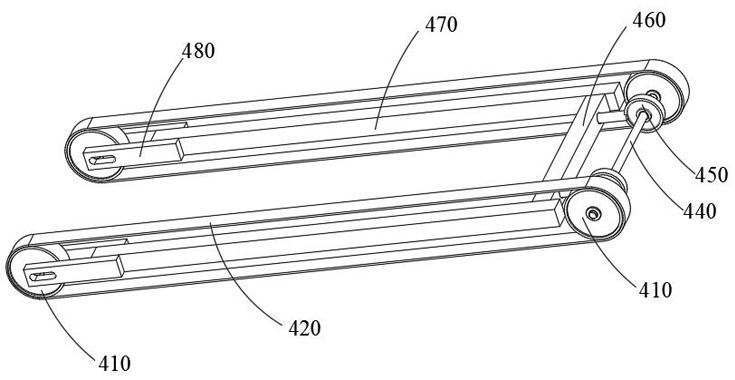

[0038] The quality inspection department 300, the quality inspection department 300 includes the rotating spindle 310 of the quality inspection department, and the rotating spindle 310 of the quality inspection department is evenly distributed with a plurality of aluminum plate storage boxes 320, and the length of the aluminum material plate is longer than the length of the aluminum material plate storage box 320 , the aluminum plate storage box 320 is provided with an aluminum plate limit card column 321; the size of the inner cavity of the aluminum material plate storage box 320 gradually decreases from the opening to the ...

Embodiment 2)

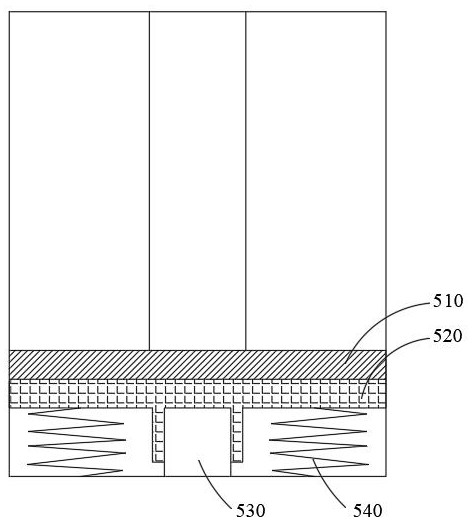

[0049] The difference between this embodiment and Embodiment 1 is that the aluminum plate storage box 320 is provided with an antioxidant coating assembly,

[0050] The antioxidant coating assembly includes a coating layer 510, a sliding seat 520, a sliding column 530, and an elastic member 540. The coating layer 510 is connected to the sliding seat 520, the sliding seat 520 is slidably connected to the sliding column 530, and the elastic member 540 is connected to the aluminum material. board storage box 320 and slider 520 .

[0051] The coating layer 510 can be made of, but not limited to, materials such as sponge, which is mainly used to maintain a certain amount of antioxidant, so as to facilitate the coating of the antioxidant on the side of the aluminum plate that is not allowed to be painted. The side of the aluminum plate that is not allowed to be painted, that is, the side of the aluminum plate facing the opening of the aluminum plate storage box 320 , is also facing ...

Embodiment 3)

[0053] The difference between this embodiment and Embodiment 1 is that the output unit 400 is further provided with a labeling auxiliary plate 430 , and the labeling auxiliary plate 430 is used for assisting the lamination of aluminum plates. The labeling unit 200 may be larger than the side of the aluminum plate facing away from the opening of the aluminum plate storage box 320 according to the size of the label required, and needs to be attached to the other side, while the labeling auxiliary plate 430 is The larger label is assisted with labeling. Of course, it can be understood that even if the size of the label is smaller than the side of the aluminum sheet facing away from the opening of the aluminum sheet storage box 320, the auxiliary labeling plate 430 can make the labeling on one side more stable through elastic collision. The auxiliary labeling plate 430 is a curved baffle with good resilience, and its material can be reasonably selected according to requirements. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com