Automatic production line of waffle ingot stacking and unstacking ink-jet technology

An automatic production line and palletizing technology, which is applied in the depalletizing of objects, painting booths, spraying devices, etc., can solve the problems of high labor intensity and low automation level of workers, reduce labor intensity of workers, improve automation level, and provide production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

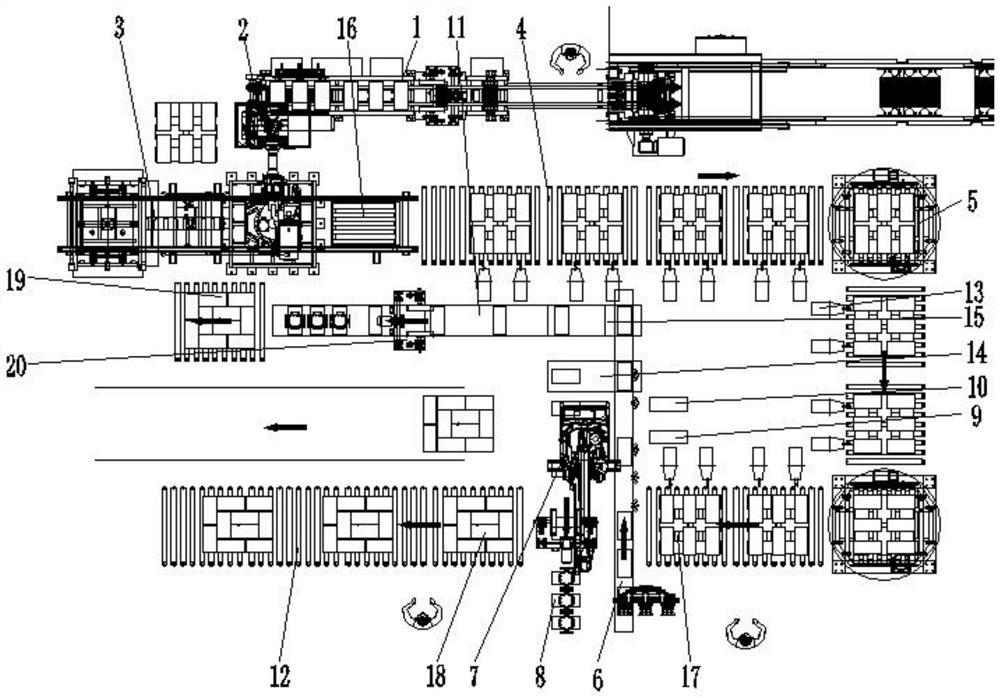

[0014] Such as figure 1 As shown, a waffle ingot stacking and unstacking inkjet process automatic production line, including the ingot transfer line 1, one side of the ingot transfer line 1 is provided with a 1# robot body 2, and the 1# robot body 2 The other side of the intermediate palletizing position 16 is provided with a pallet warehouse automatic supply system 3 on one side of the intermediate palletizing position 16, and the other side of the intermediate palletizing position 16 is provided with an intermediate pallet conveying system. Line 4 and corner conveying line 5, the end of described intermediate pile conveying line 4 is provided with unstacking position 17, and one side of described unstacking position 17 is provided with 2# robot body 7, and described 2# robot body 7 and all A destacking conveying line 6 is arranged between the destacking positions 17, and a paint spraying mechanism 9 and an inkjet mechanism 10 are arranged on the destacking conveying line 6, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap