Compressor

A technology for compressors and connecting pipes, applied in the field of compressors, can solve the problems of single installation form, limited application scope, complex variable structure, etc., and achieve the effects of convenient use, convenient and flexible application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

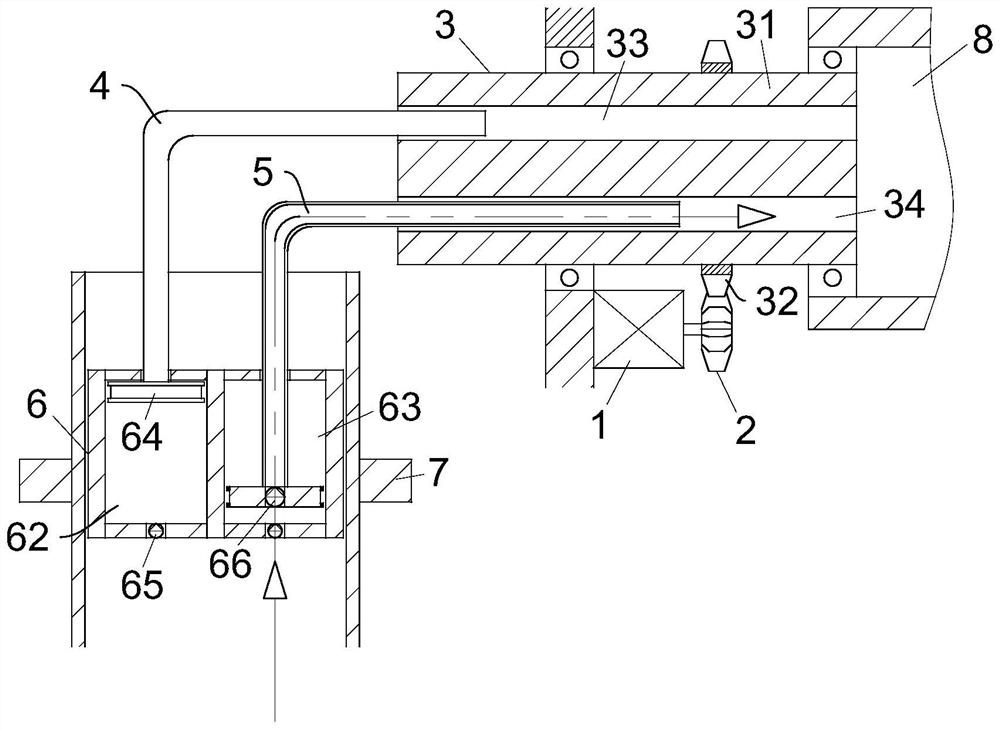

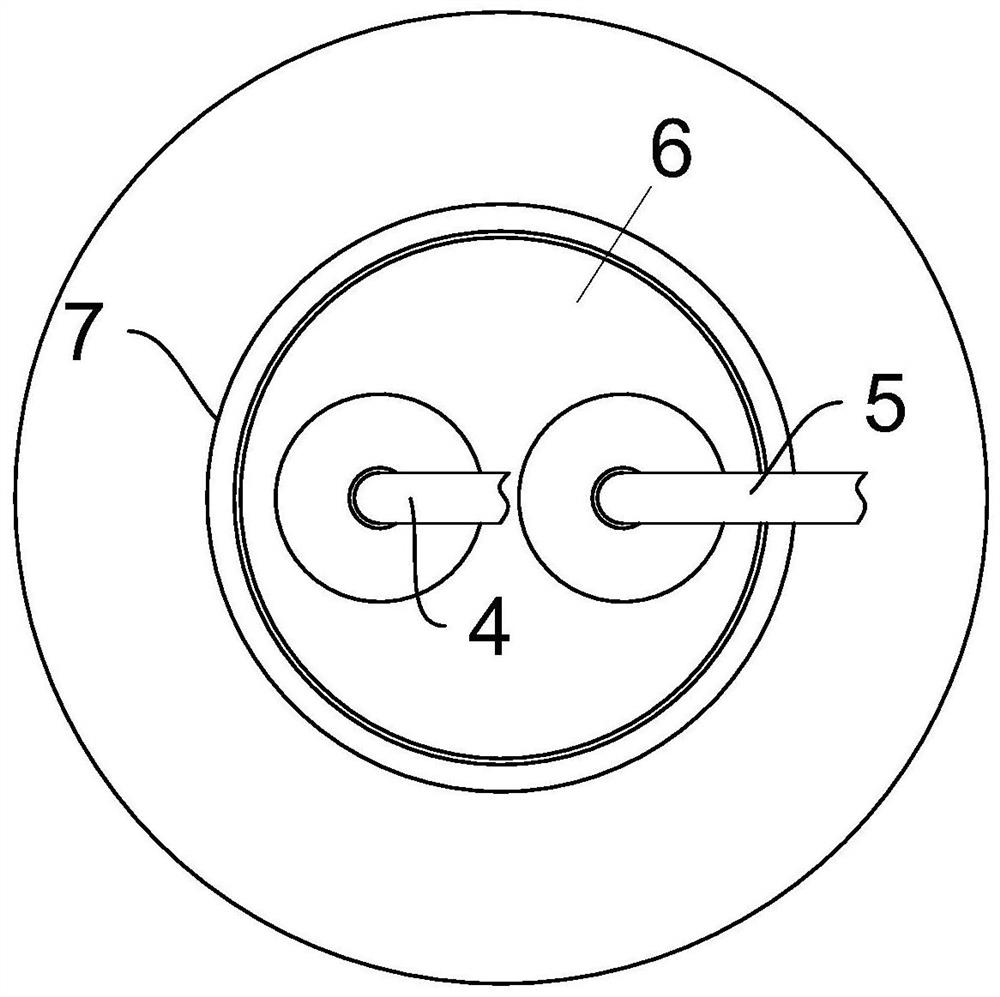

[0023] refer to figure 1 and figure 2 , a compressor, comprising a motor 1, the motor 1 is connected to a gear 2, the gear 2 meshes with a rotating column 3, the right end of the rotating column 3 is rotatably connected to a storage chamber 8, and the left end of the rotating column 3 is slidably connected to at least one first connecting pipe 4 and at least one first connecting pipe 4 Two connecting pipes 5, the two ends of the first connecting pipe 4 and the second connecting pipe 5 communicate with the inner pumping cylinder 6 and the storage chamber 8 respectively, and the inner pumping cylinder 6 rotates on the mounting seat 7; the inner pumping cylinder 6 is provided with The first pumping chamber 62 and the second pumping chamber 63 correspond to the number of the first connecting pipe 4 and the second connecting pipe 5 and communicate with each other. Both the first pumping chamber 62 and the second pumping chamber 63 are slidingly sealed. Connect the piston 64, the ...

Embodiment approach

[0025] As an embodiment of the present invention, the rotating column 3 includes a rotating column main body 31, and a ring gear 32 is fixed outside the rotating column main body 31, and the ring gear 32 meshes with the gear 2. The rotating column main body 31 is provided with a first sliding ventilation groove 33 and The second sliding ventilation groove 34 , the first connecting pipe 4 and the second connecting pipe 5 are sealed and slidably inserted into the first sliding ventilation groove 33 and the second sliding ventilation groove 34 respectively.

[0026] As an embodiment of the present invention, the number of the first connecting pipe 4 and the second connecting pipe 5 is an even number, which ensures the stress stability of the internal pumping cylinder 6 as a whole when the piston 64 moves.

[0027] As an embodiment of the present invention, the cylinder body of the inner pumping cylinder 6 is equipped with a regulating valve for communicating the first pumping cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com