Flue gas recirculation combustion chamber with variable swirl

A technology of recirculation combustion chamber and combustion chamber, which is applied in combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems that emission parameters cannot be guaranteed, maintained at design strength, and flue gas return flow cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

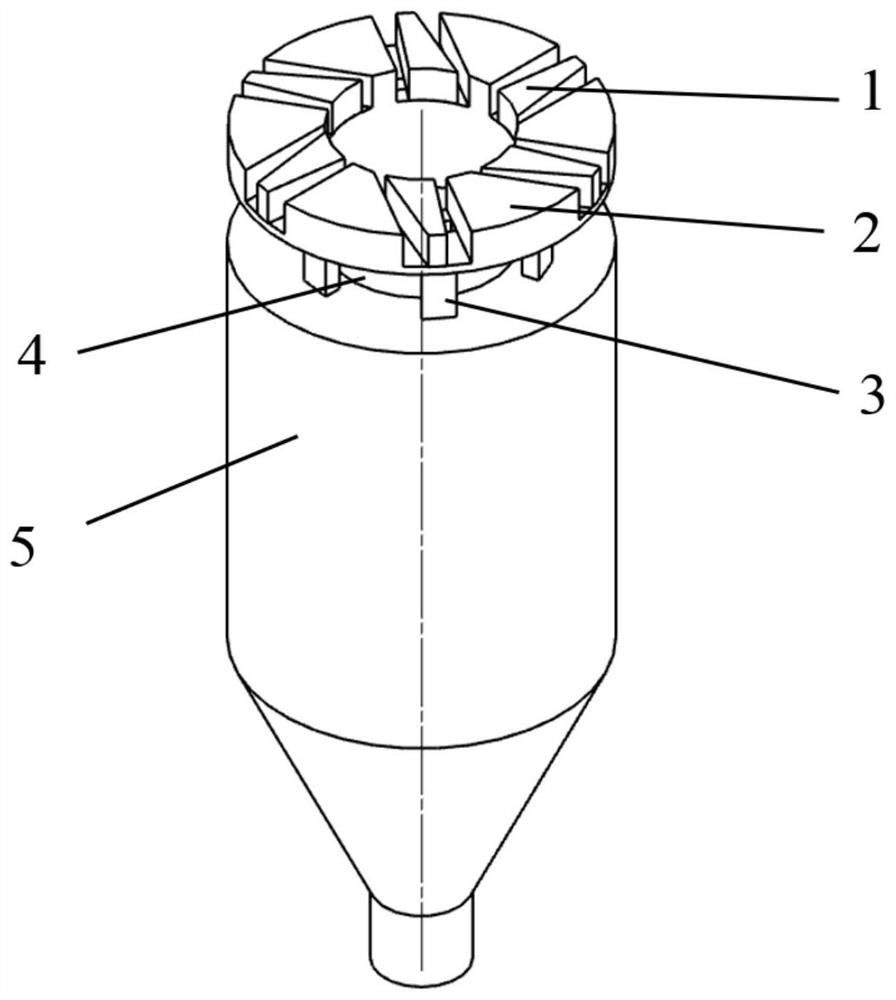

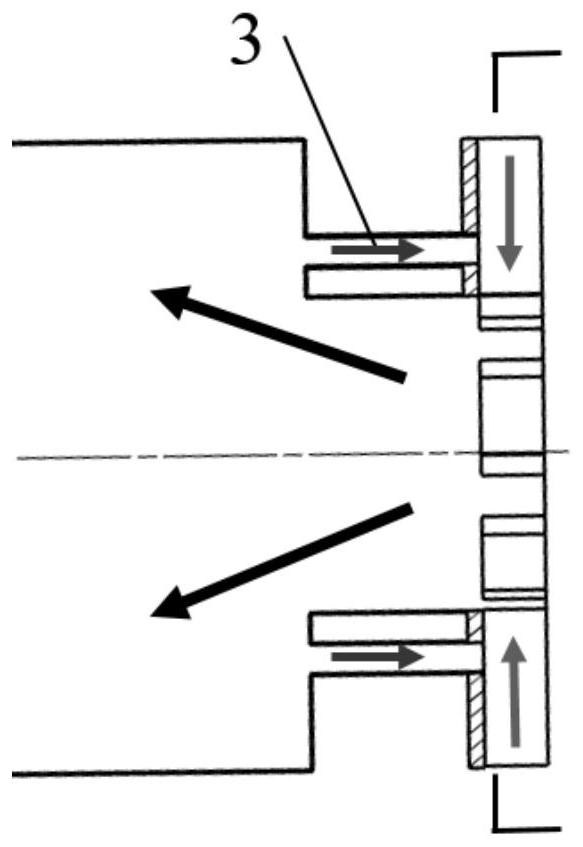

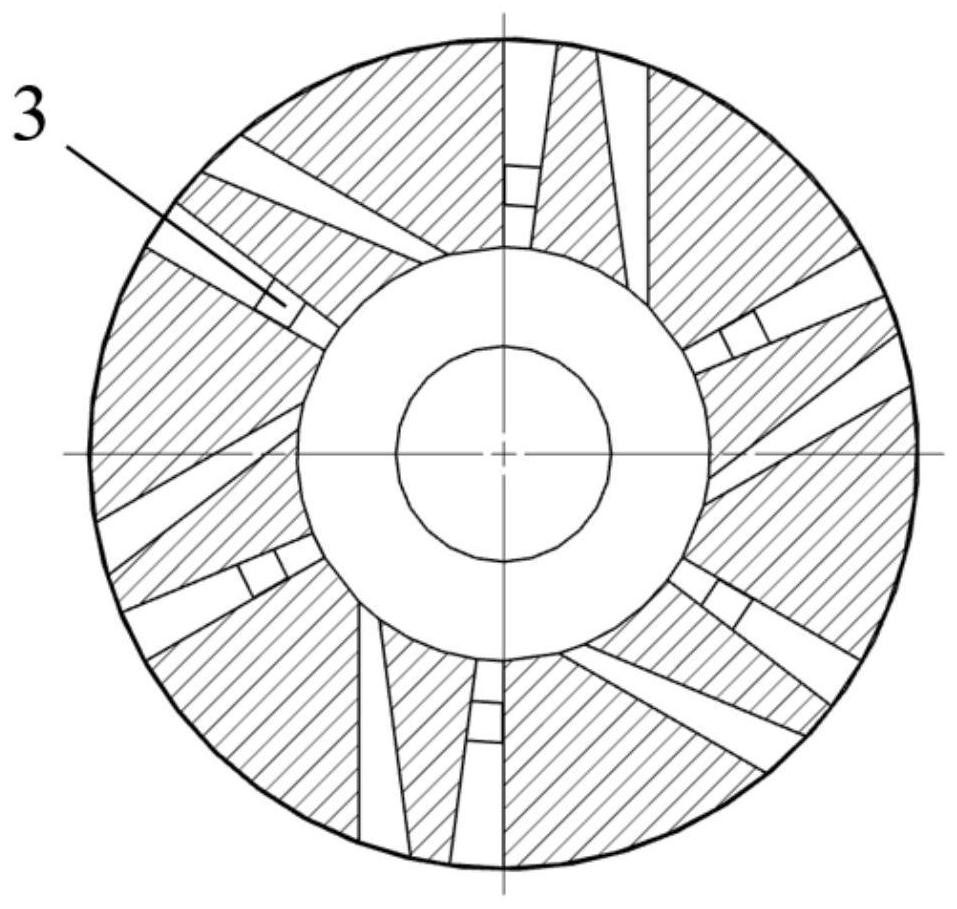

[0017] Such as Figure 1-4 As shown, a flue gas return combustion chamber with variable swirl flow includes five parts: fixed swirl blade 2, moving swirl blade 1, flue gas return channel 3, combustion chamber throat 4, and combustion chamber cavity 5 . The fixed swirler consists of six fixed swirler blade modules of the same shape and size, which are fixed to the combustion chamber by welding or other methods. Each fixed swirler blade module has two arc sides, one radial side and one Tangential side, the inner arc side 14 is the same as the inner diameter of the combustion chamber throat 4, wherein the extension line of the radial side 11 passes through the center of the swirler, and the radial direction of the tangential side 13 and its adjacent fixed swirler blade module The side 11 is parallel; the mobile swirler is composed of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com