Efficient energy-saving glass kiln

A glass furnace, energy-saving technology, applied in glass furnace equipment, glass manufacturing equipment, dispersed particle filtration, etc., can solve the problems of high energy consumption, improve processing quality, improve heating efficiency and effect, and reduce bubble generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

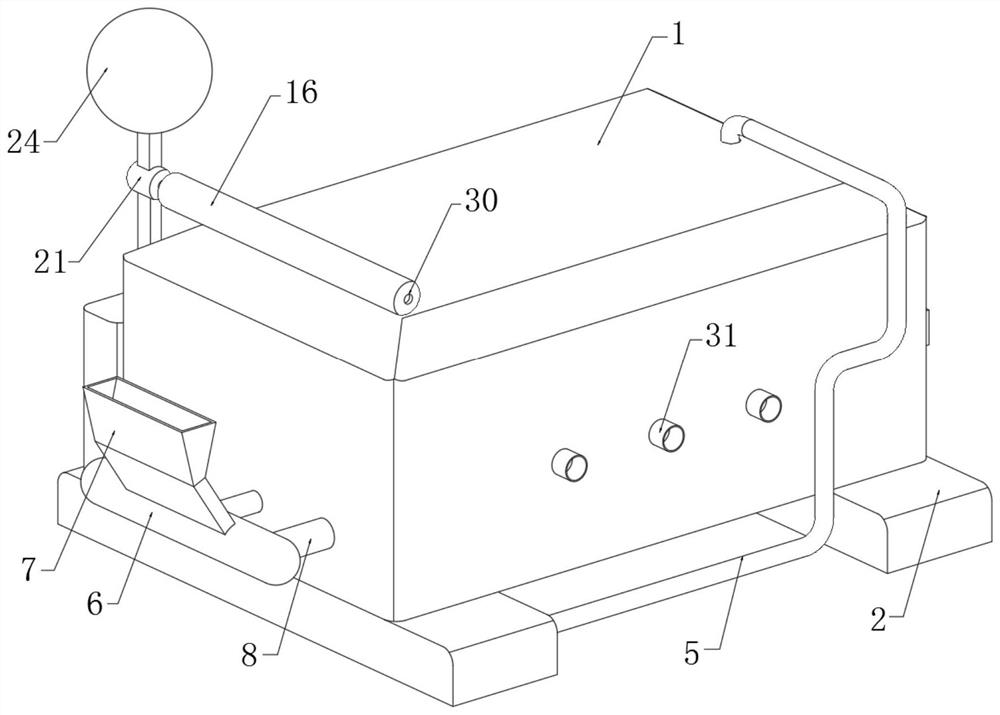

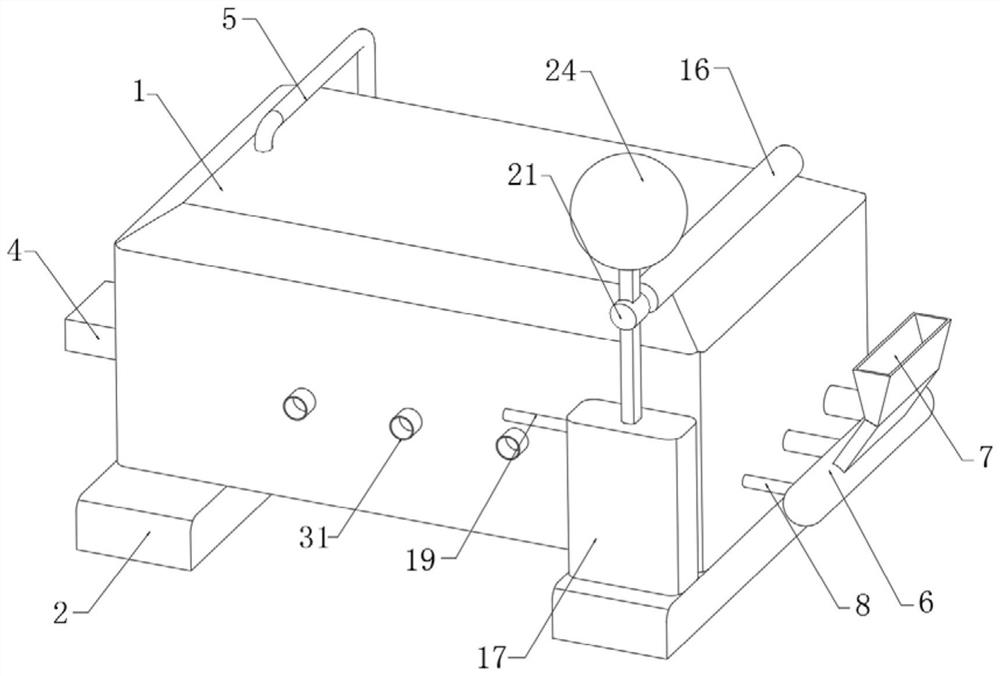

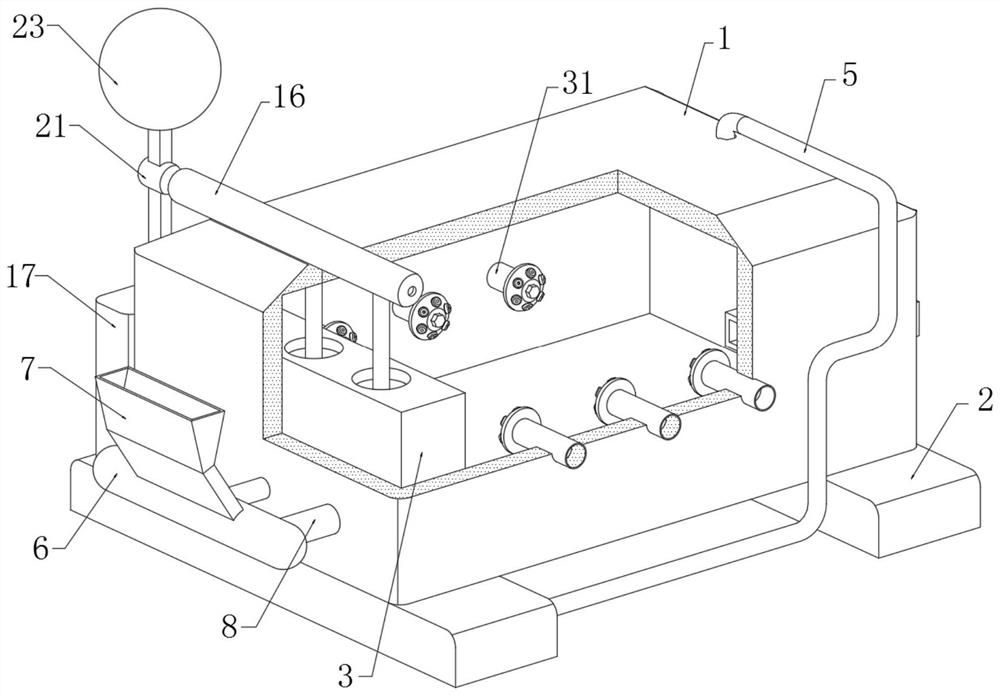

[0032] Refer Figure 1-6 A high-efficiency energy-saving glass kiln, including the furnace body 1, and the bottom of the furnace body 1 fixes two symmetric base 2, one side inner wall of the furnace body 1 fixes the transfer chamber 3, the internal setting of the transfer chamber 3 There is a pretreatment mechanism, and the inner wall of the other side of the furnace body 1 is inserted with an effluent tube 4, and the outer wall provided with the side of the shift chamber 3 is provided with a feed allocation mechanism. The upper end of the furnace is inserted with a exhaust pipe. 5, the other end of the exhaust pipe 5 communicates with the base 2 adjacent the transfer chamber 3, and the inner portion of the furnace body 1 is provided with a jet heating mechanism, and the upper end of the base 2 of the transfer chamber 3 is fixed to the cooling box 17, the cooling box. The inner part of 17 is provided with a condensation recovery mechanism.

[0033] The pretreatment mechanism includ...

Embodiment 2

[0048] Refer Figure 7 The difference between the embodiment and the embodiment is different from the injection heating mechanism, and the injection heating mechanism includes a plurality of injection tubes 31 on both sides of the furnace body 1, and two injection tubes 31 on one side of the furnace body 1 On the side, three jet tubes 31, the five injection tube 31 is displaced, that is, the injection range of the respective injection tube 31 does not overlap, the injection tube 31 of the intermediate position impinges the gap position of the two injection tube 31, the furnace body 1. The inner bottom rotation is rotated with three stirring shafts 32, each circumferential side wall of each agitating shaft 32 fixedly coupled with a plurality of drive leafs 33, and a plurality of stirring rods 34 are fixed in the lower circumferential side wall of each agitating shaft 32. The drive leaf 33 is located above the fluid liquid surface, and the area is larger than the reception impact, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com