Small heat accumulating type household garbage pyrolysis gasification furnace

A technology of pyrolysis gasification and domestic waste, applied in the direction of incinerators, combustion types, lighting and heating equipment, etc., can solve the problems of high operating costs, complex systems, and high costs, and achieve low operating costs, simple system structure, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

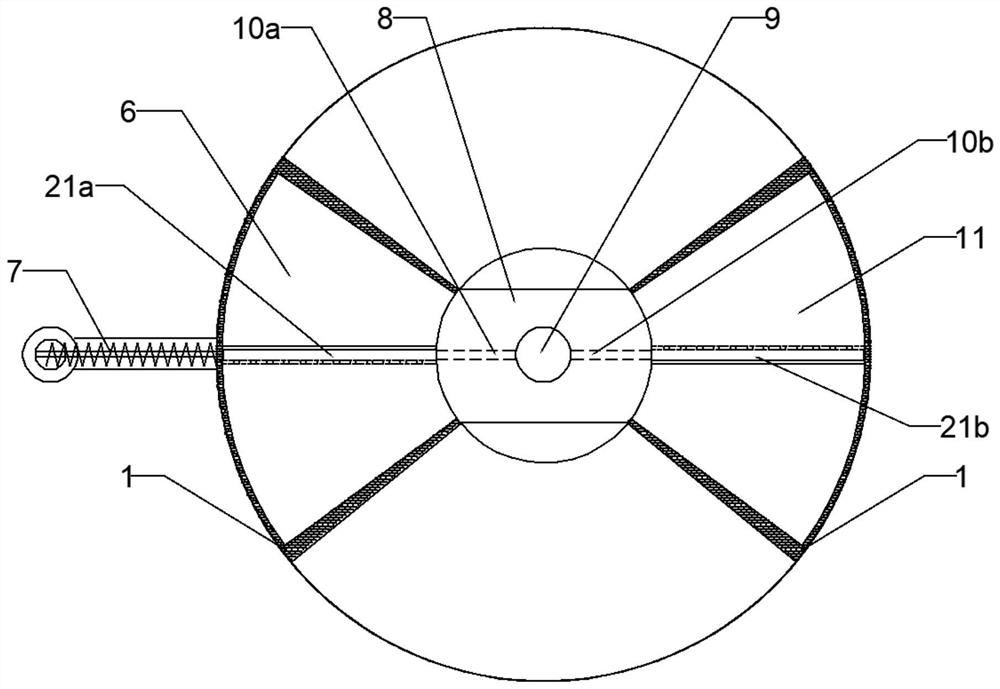

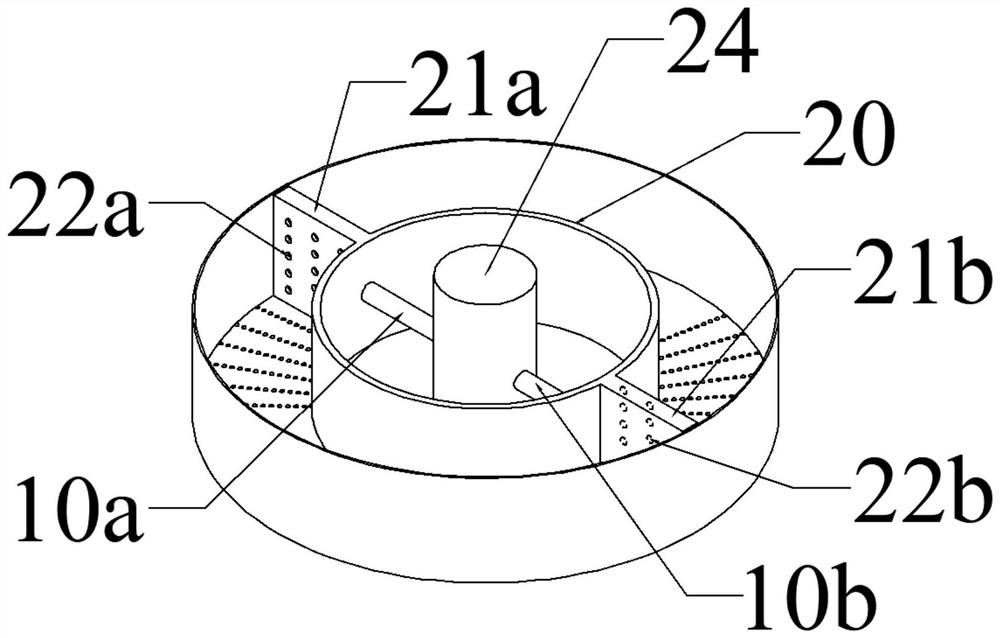

[0024] see Figure 1 to Figure 4 , a small-sized regenerative domestic waste pyrolysis gasification furnace, the pyrolysis gasification furnace includes a cylindrical shell 1, and a pyrolysis gasification chamber 6 and a catalytic reforming chamber 11 are symmetrically arranged left and right in the cylindrical shell 1 , the middle part of the pyrolysis gasification chamber 6 and the catalytic reforming chamber 11 is respectively provided with a first packing layer 5 and a second packing layer 12; the catalyst particles placed on the first packing layer 5 and the second packing layer 12 are made of stainless steel The orifice plate 51 supports each other; the upper part of the pyrolysis gasification chamber 6 and the catalytic reforming chamber 11 communicates through the horizontal flue 8; the bottom of the pyrolysis gasification chamber 6 is arranged with a slag discharge pipe 19 and an air inlet 23 And several hoods 4, the slagging pipe 19 is connected with the slagging val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com