Weighing sensor based on automatic adjusting mechanism

A weighing sensor and automatic adjustment technology, which is applied in the field of weighing sensors, can solve problems such as manual maintenance, difficulty in normal work, and poor measurement accuracy of weighing sensors, so as to ensure weighing accuracy, improve disassembly convenience, and improve The effect of job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

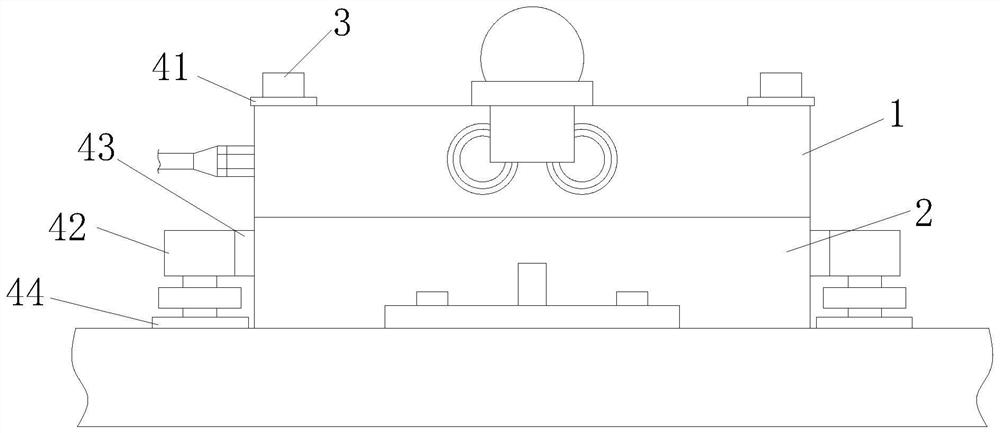

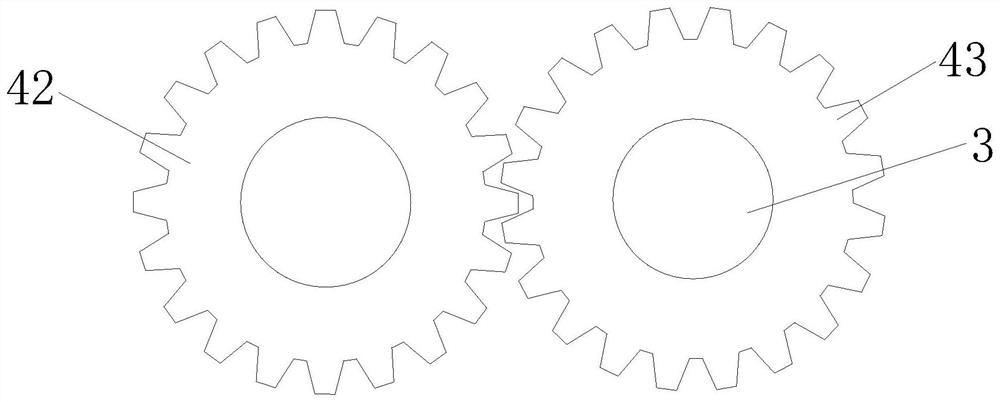

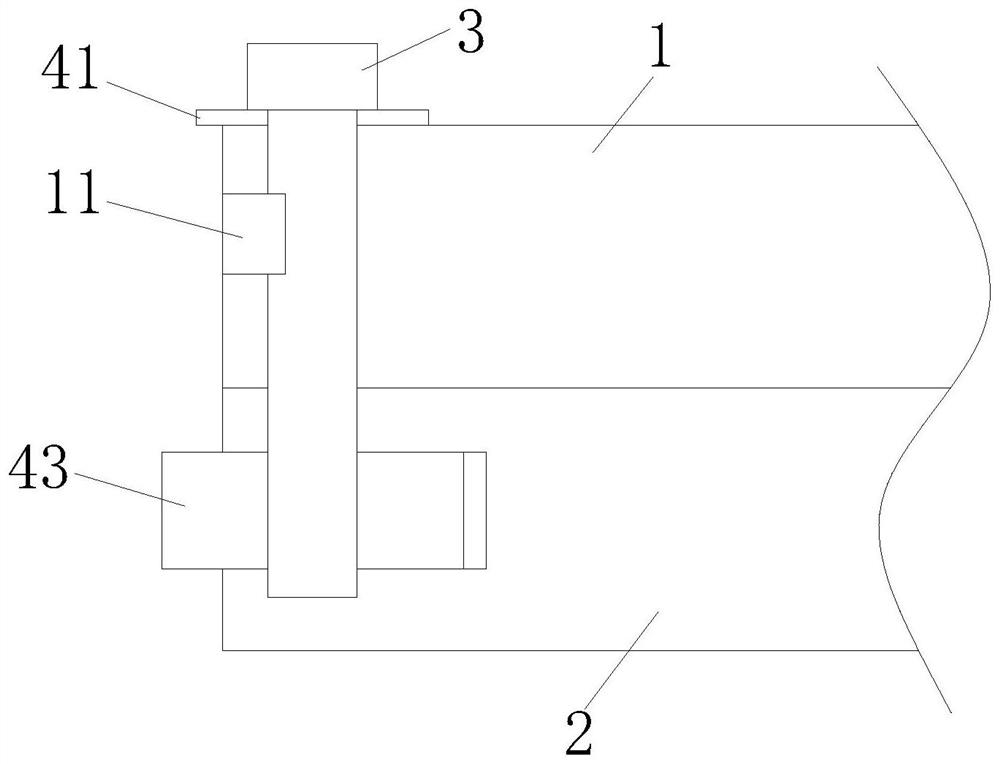

[0018] Embodiment 1, referring to the accompanying drawings, a load cell based on an automatic adjustment mechanism, including an elastic body 1, a base 2, and a bolt 3 threaded on the base 1 after passing through the elastic body 1; also includes an adjustment mechanism; the adjustment mechanism Sensing the tightness of the connection between the elastic body 1 and the base 2, and adjusting the tightness of the connection between the elastic body 1 and the base 2 by driving the bolt 3 to rotate;

[0019] Introduce an adjustment mechanism on the load cell to monitor the tightness of the connection between the elastic body 1 and the base 2, and adjust the connection tightness between the elastic body 1 and the base 2 by driving the bolt 3 to rotate after the elastic body 1 and the base 2 are loosely connected , so that the firmness of the connection between the elastic body 1 and the base 2 is always maintained, avoiding the problem of weighing errors caused by the loose connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com