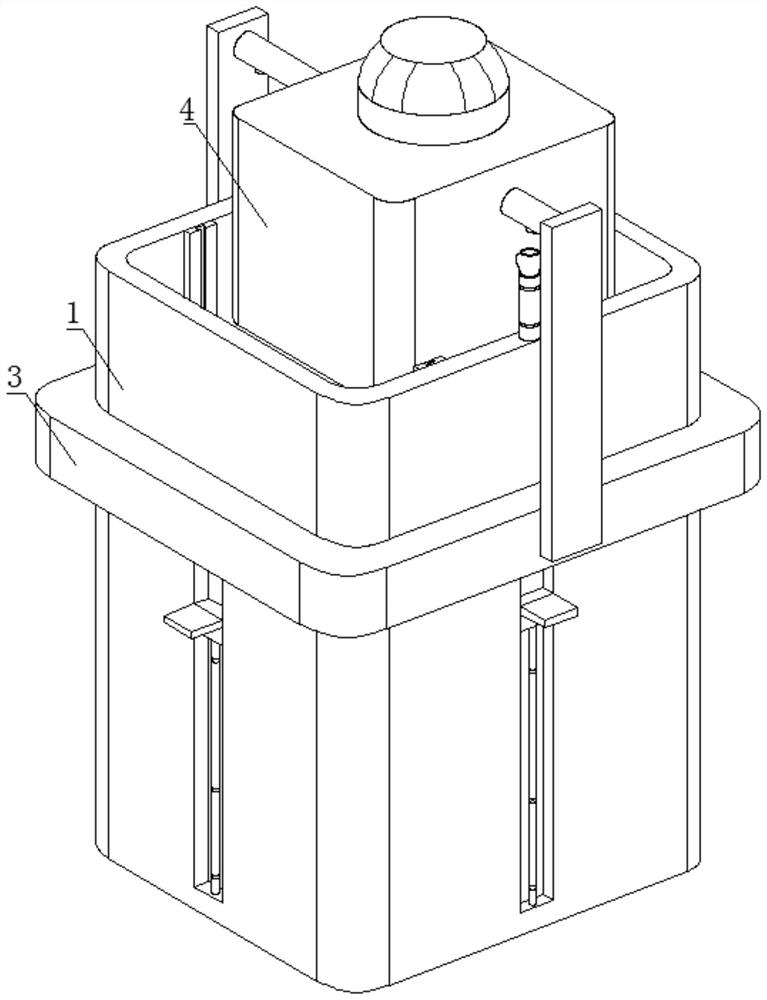

Uniform mixing device and method for high-concentration uniform nitro-compound fertilizer

A nitro compound fertilizer, high-concentration technology, applied in chemical instruments and methods, mixers with rotary stirring devices, mixers, etc. effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

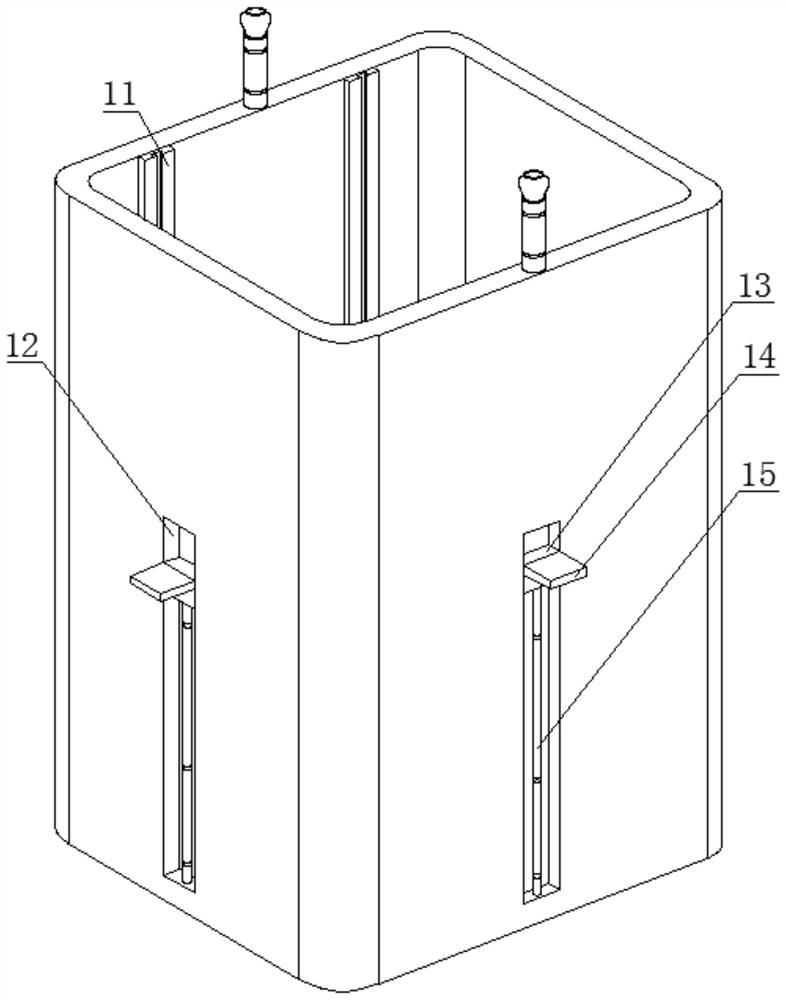

[0051] For further better explanation above-mentioned embodiment, the present invention also provides a kind of embodiment, a kind of implementation method of the mixing device of high-concentration uniform nitro compound fertilizer, comprises the following steps:

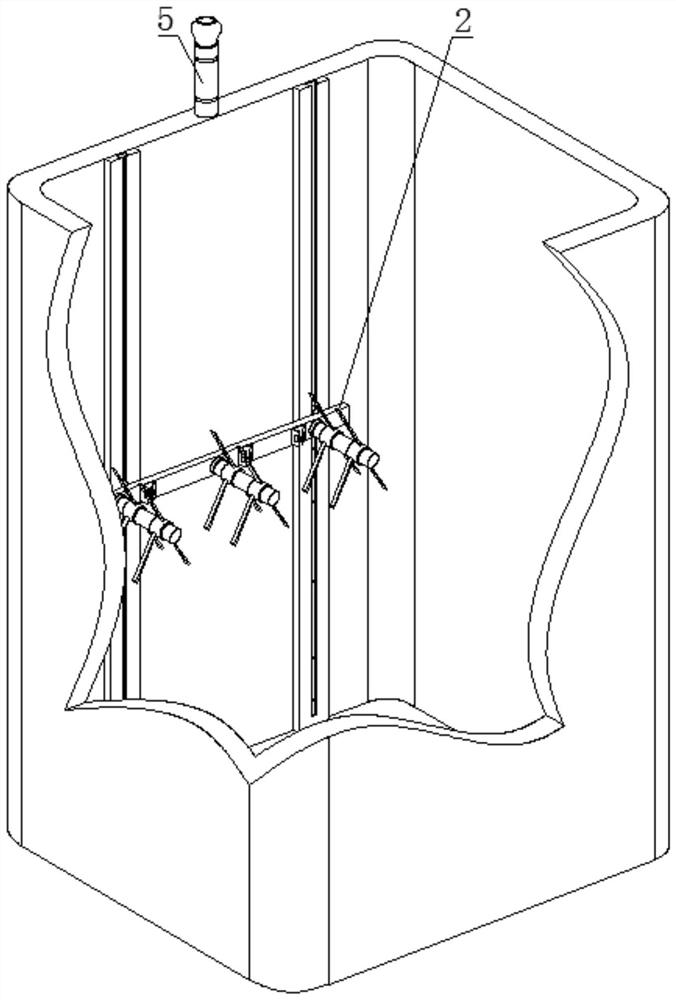

[0052] Step 1: Put the nitro compound fertilizer inside the main box 1 and mix it with the agitating paddle 261. During the mixing process, continuously change the position of the agitating paddle 261 by using the electric push rod 23;

[0053] Step 2: When agitating the surface of the paddle 261 with a lot of nitro compound fertilizer remaining, disconnect the current of the electromagnetic insert A213 and the electromagnetic insert B223 to make the magnetism disappear, so that the main connecting plate 21 rotates at a certain angle, and the movable door panel 25 is opened under the influence of gravity, and the airflow produced by the fan blade 263 will be ejected from the air outlet groove 24, and the agitating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com