Screening structure for duck feed treatment

A duck feed and screening technology, which is applied in the direction of separating solids from solids by air flow, sieving, solids separation, etc., can solve the problems of decreased production performance, insufficient intake of nutrients, affecting the taste of feed, etc. Impact, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

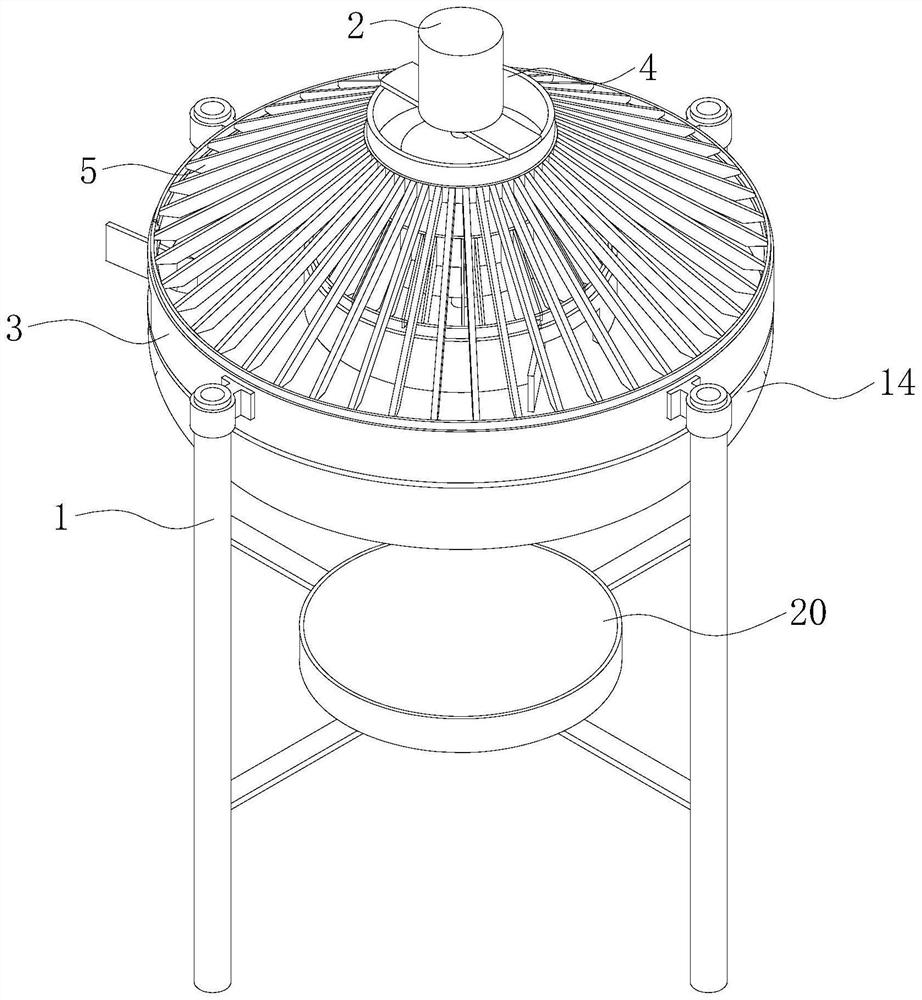

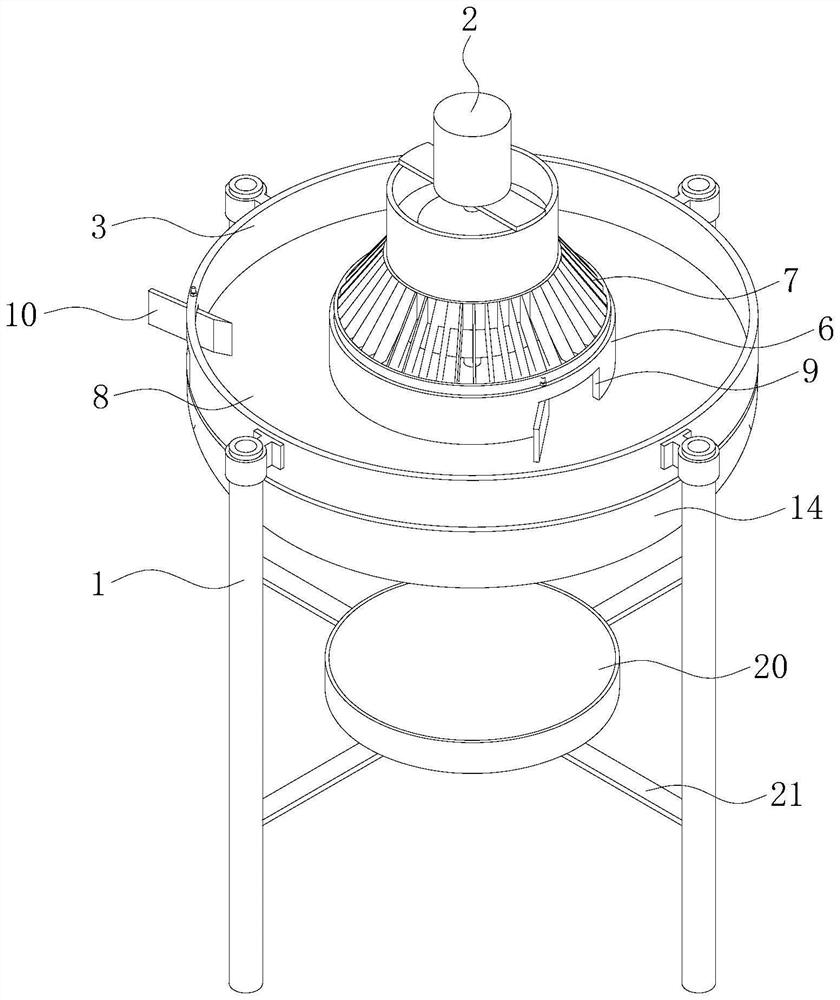

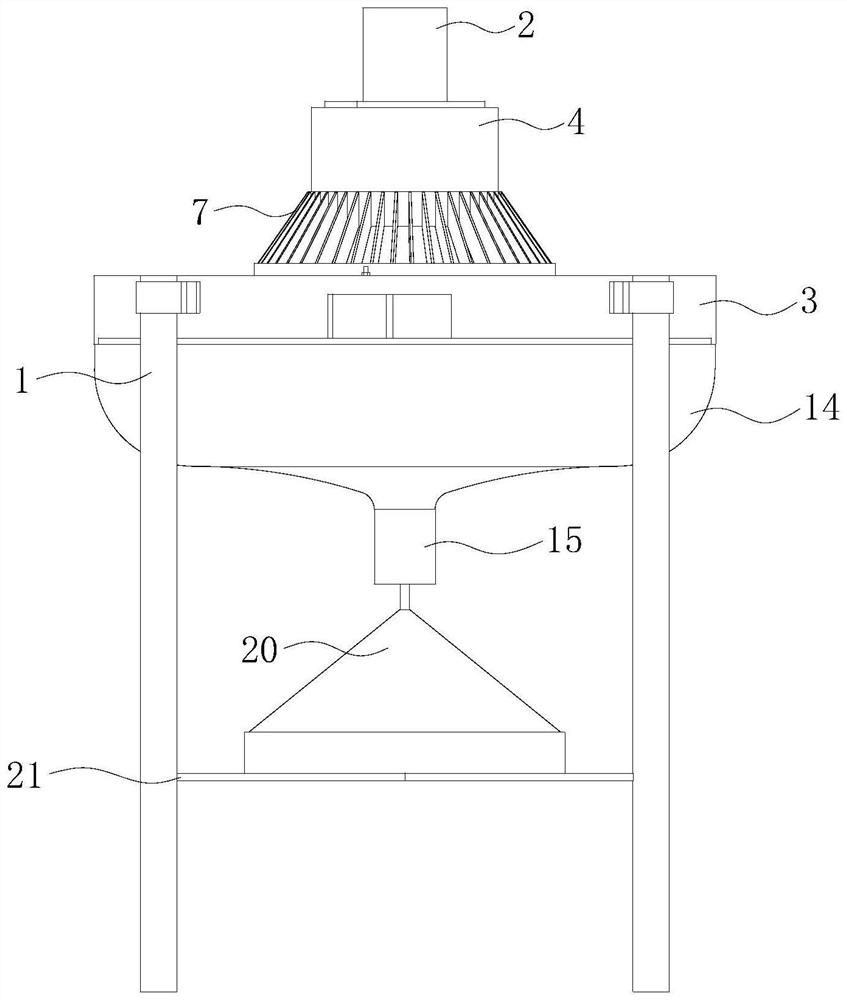

[0024] Such as Figure 1-6 As shown, a screening structure for duck feed processing includes four supports 1 and a motor 2, the motor 2 is located above the four supports 1, an outer ring 3 is arranged between the upper ends of the four supports 1, and the outer ring 3 There is a feeding cylinder 4 above, and the motor 2 is fixedly connected to the upper end of the feeding cylinder 4. The size of the motor 2 does not affect the feeding of the feeding cylinder 4, and the outer ring 3 and the circumferential surface of the feeding cylinder 4 are fixed by several baffles A5 The outer ring 3 is provided with an inner ring 6, and the inner ring 6 is fixedly connected to the circumferential surface of the feeding cylinder 4 through several baffles B7. The baffle B7 is located below the baffle A5. The feeding cylinder 4, the outer ring 3 and the inner ring 6 are arranged concentrically, and the baffle A5 and the baffle B7 are installed equidistantly. , the smaller aperture of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com