Plate burr removing device

A technology for removing burrs and plates, applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., can solve problems such as high labor intensity, and achieve the effect of reducing labor intensity and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

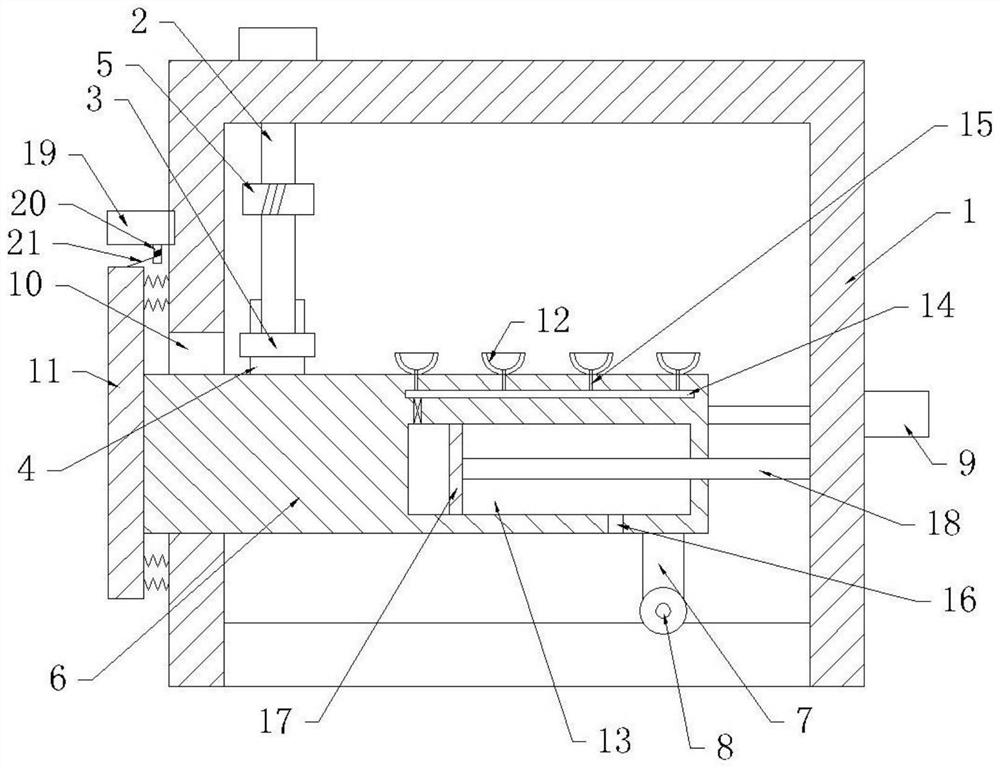

[0024] The reference signs in the drawings of the description include: mounting frame 1, rotating shaft 2, grinding disc 3, grinding roller 4, driving gear 5, support plate 6, moving rod 7, roller 8, cylinder 9, moving hole 10, buffer plate 11 , suction cup 12, gas storage channel 13, flow diversion channel 14, diversion hole 15, air filling hole 16, slide plate 17, push rod 18, dust collection box 19, rotating shaft 20, stay cord 21.

[0025] Plate burr removal device, the embodiment is basically as attached figure 1 As shown, a mounting frame 1 is included, and a driving part, a grinding part and a supporting part are sequentially arranged on the mounting frame 1 from top to bottom, and the driving part includes a driving motor. The grinding part includes a rotating shaft 2 fixed coaxially with the output shaft of the driving motor and a grinding disc 3 arranged at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com