Automobile air conditioner compressor assembly system and assembly process

An assembly system and automobile air-conditioning technology, which is applied in the direction of manipulators, manufacturing tools, hand-held tools, etc., can solve the problems of piston falling off, high labor intensity, and low production efficiency, and achieve precise installation, reduce labor intensity, and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

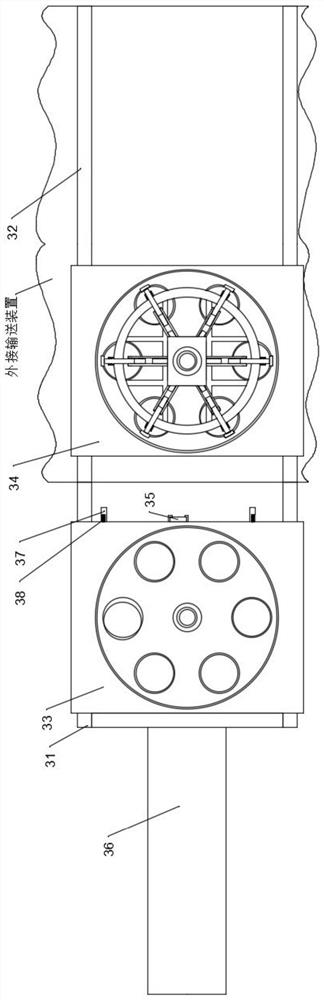

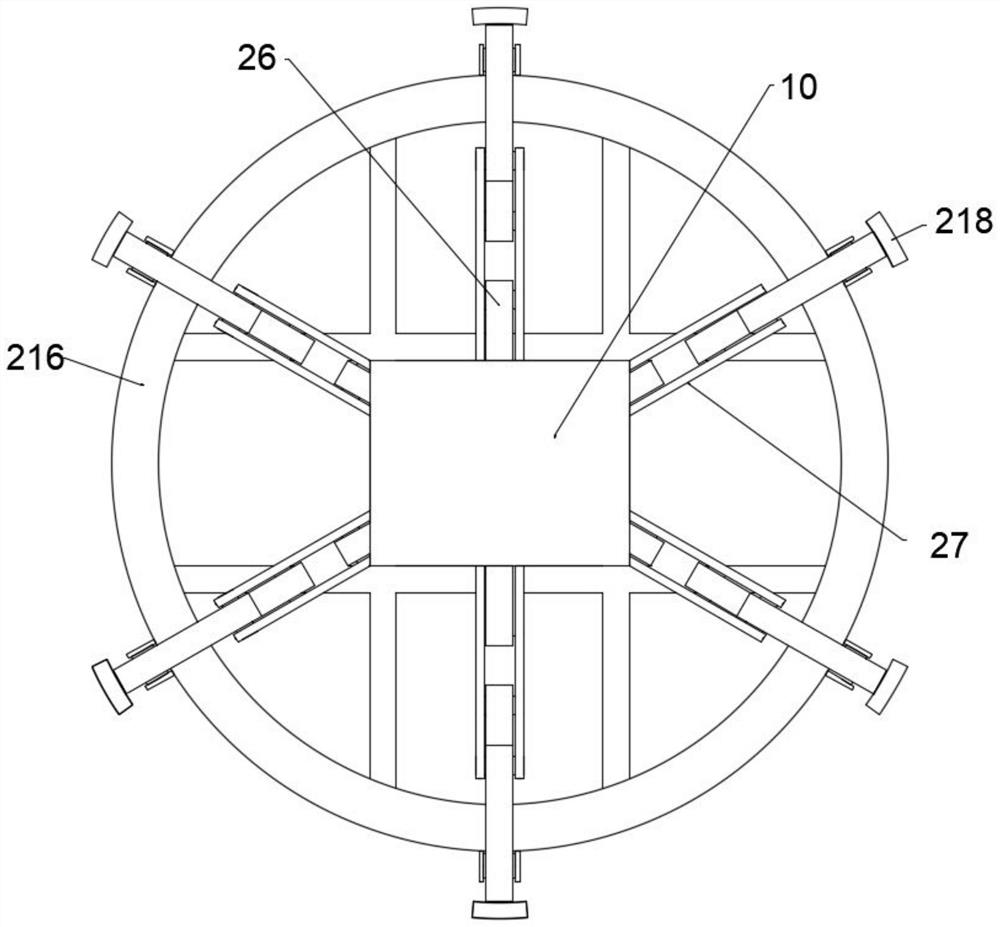

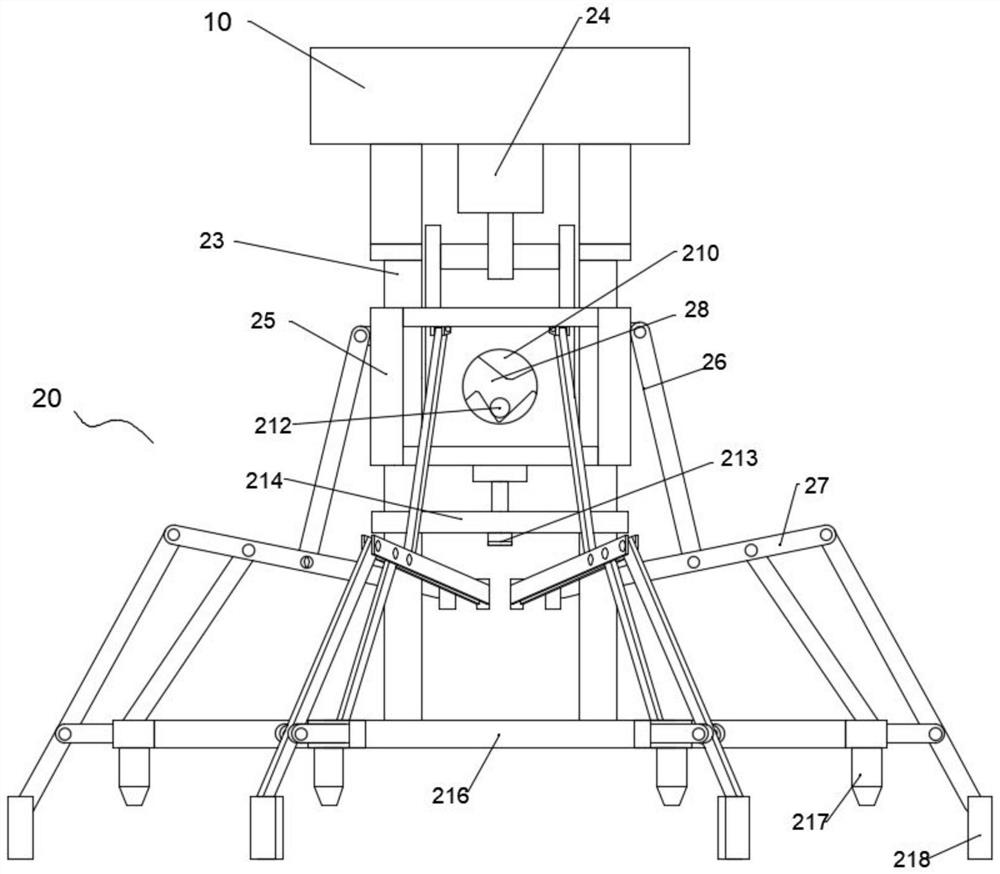

[0035] Embodiment 1: as Figure 1 to Figure 8As shown, an automobile air-conditioning compressor assembly system includes a manipulator 10 installed above the assembly station of the swash plate assembly of the external conveying equipment, a positioning fixture 20 installed on the manipulator 10, and a cylinder body-profiling cylinder body quick change assembly 30 and the controller that controls the manipulator 10 and the cylinder body-profiling cylinder quick change assembly 30 to switch the positions of the cylinder body and the profiling cylinder body, the positioning fixture 20 includes a vertical guide rail 23 and a cylinder one 24 installed on the manipulator 10, A positioning assembly is provided on the guide rail 23, and the positioning assembly includes a frame body 216 installed at the bottom of the vertical guide rail 23, a plurality of positioning rods 217 mounted on the frame body 216 at equal intervals and adapted to the reserved holes at the top of a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com