Manufacturing technology of high-strength laminated wood

A manufacturing technology, glulam technology, applied in the field of high-strength glulam manufacturing, can solve the problems of large porosity, no effective improvement of glulam strength, and low wood elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below in conjunction with examples.

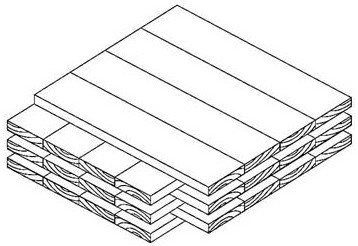

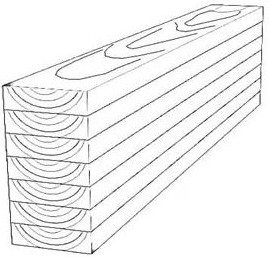

[0027] As described in the background art, existing glulams and cross-laminated lumbers are insufficient in strength. In order to solve the above-mentioned technical problems, the invention discloses a kind of manufacturing technology of high-strength glued wood, comprising the following steps:

[0028] Step S1, perform finger-joining treatment on the wood raw materials, wherein the finger-joining requirement is a butt-joint horizontal type, the length of the finger-tenon of the finger-joint is greater than 10mm, the inclination ratio of the finger-tenon slope is less than 1 / 7.5, and the width of the top of the tooth minus the width of the bottom of the tooth is greater than 0.1mm. Through the above treatment, the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com