Automatic stacking equipment for anaerobic water stop copper sheets

An automatic technology for water-stop copper sheets, which is applied to the parts and packaging of strapping machines, can solve the problem of uneven placement of water-stop copper sheets, easy loosening and slipping of water-stop copper sheets, and difficulty in stacking and neatly placing water-stop copper sheets Putting and other problems, to save space and manpower, neatly placed, to prevent slipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

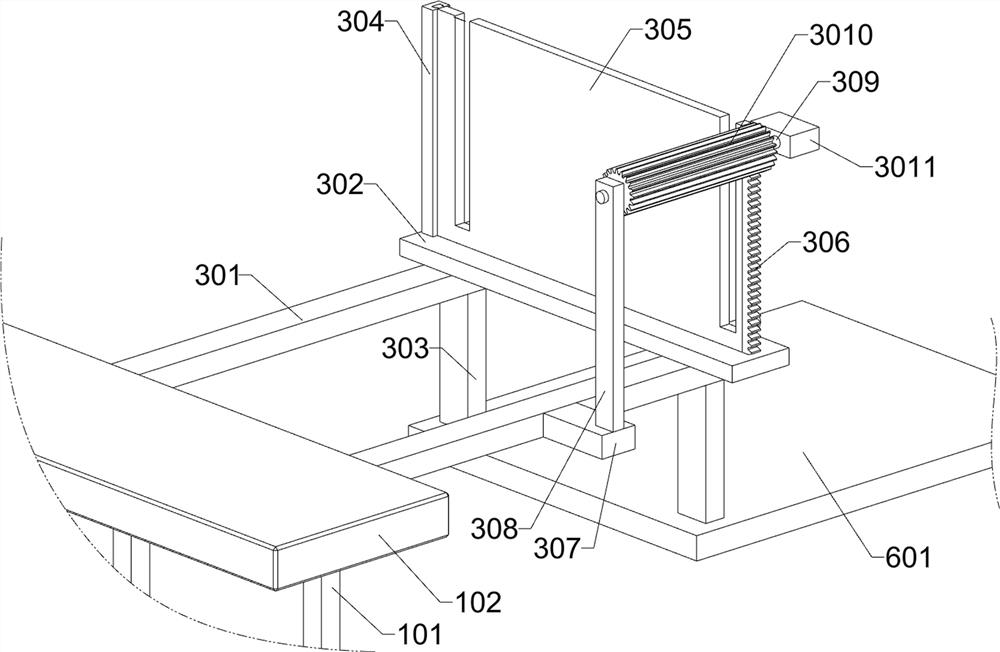

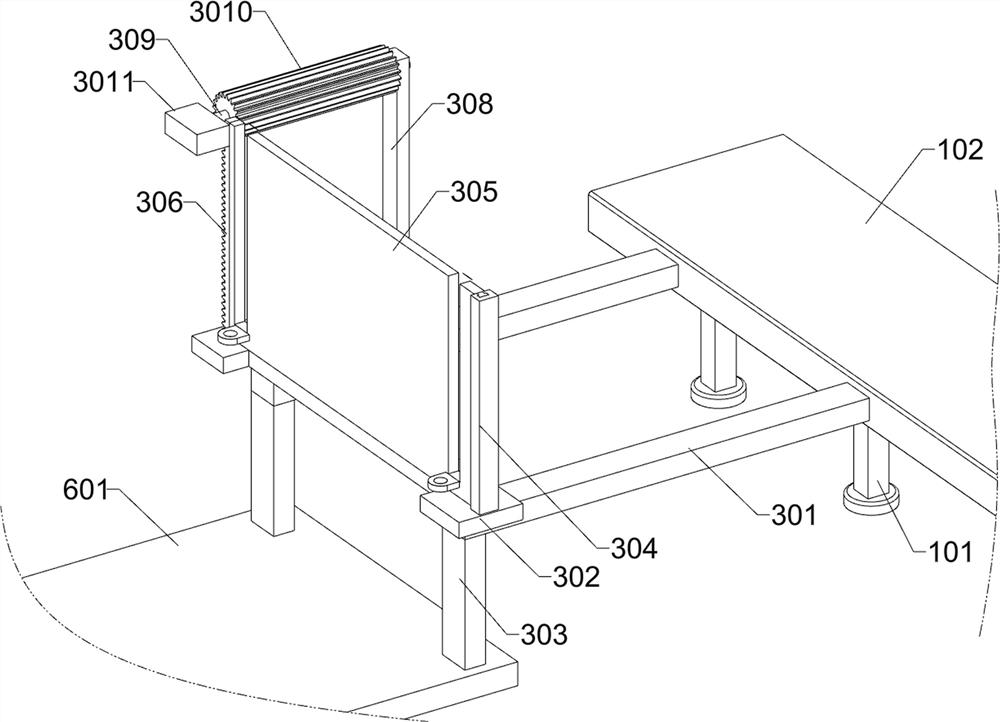

[0032] An automatic stacking device for oxygen-free water-stop copper sheets, such as Figure 1-11 As shown, it includes a transmission control system 1, a material clamping system 2, a material barrier system 3, a material holding system 4, and a loading discharge system 6; the left part of the transmission control system 1 is connected to the material clamping system 2; the transmission control system A material blocking system 3 is installed on the left rear of the system 1; a material holding system 4 is installed on the left side of the material blocking system 3; a loading discharge system 6 is installed under the material holding system 4.

[0033] When the water-stop copper sheet needs to be packaged, the operator turns the water-stop copper sheet into the material clamping system 2, controls the material clamping system 2 to clamp and fix the water-stop copper sheet, and first turns the water-stop copper sheet over a hundred times. Eighty degrees, make the flat surfac...

Embodiment 2

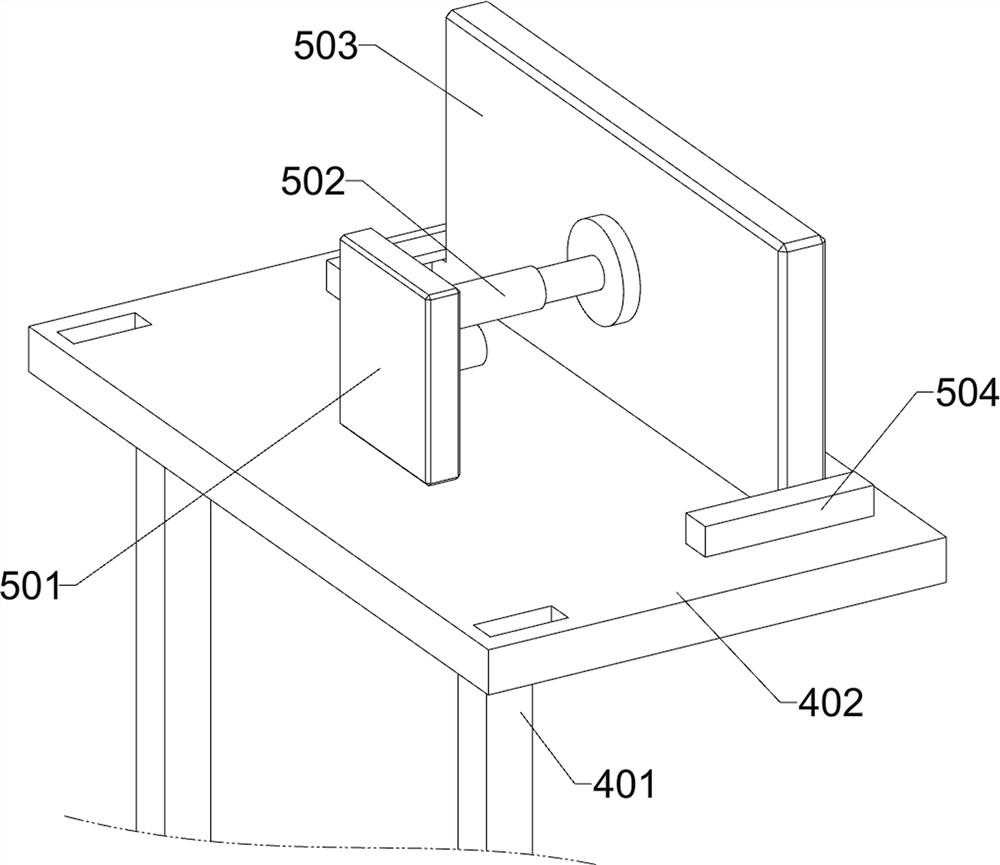

[0044] On the basis of Example 1, such as figure 1 and Figure 12 As shown, a material pushing system 5 is also included, and a material pushing system 5 is installed on the rear part of the upper side of the material holding system 4. The material pushing system 5 includes a twelfth mounting plate 501, a third electric push rod 502, The material push plate 503 and the limit block 504; the twelfth installation plate 501 is installed in the middle of the upper side of the ninth installation plate 402; the third electric push rod 502 is fixedly connected to the right side of the twelfth installation plate 501; the third electric push rod The telescopic end of 502 is fixedly connected with a material push plate 503; the upper side of the ninth mounting plate 402 is fixedly connected with two limit blocks 504, and the two limit blocks 504 are respectively located on the front and rear sides of the material push plate 503; the two limit blocks 504 is slidingly connected with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com