Preparation method of POY/FDY polyester-polyester composite yarn

A composite yarn and polyester technology, applied in the field of polyester fiber, can solve the problems of low weaving processing efficiency, low shrinkage in boiling water, and difficulty in controlling the fiber aggregate structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

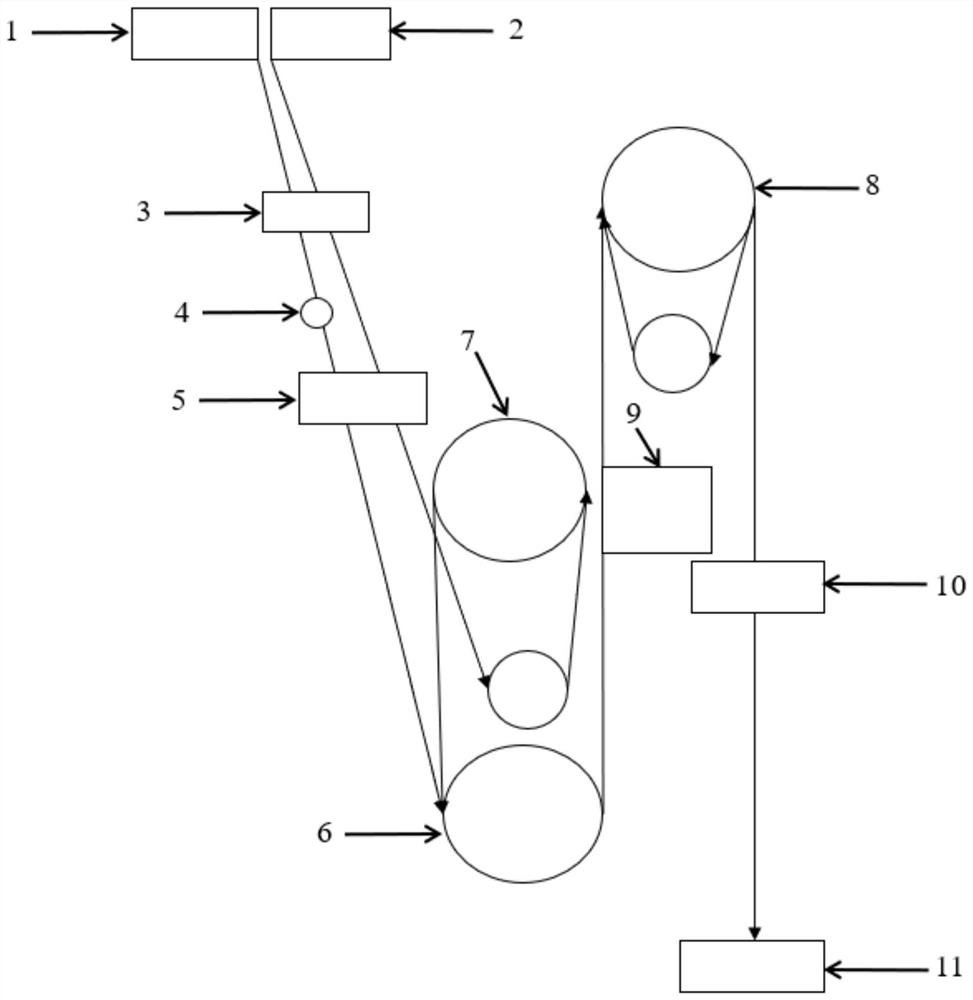

[0034] Such as figure 1 As shown, a preparation method of POY / FDY polyester composite yarn, the polyester POY yarn with a monofilament fineness of 1dtex is sequentially cooled, oiled, guided and pre-networked, and the polyester FDY yarn with a monofilament fineness of 1dtex is sequentially processed. After the processes of cooling, oiling, pre-internetting and the first hot roller GR1 7, the polyester POY yarn and the polyester FDY yarn are plied in the godet SR1 6 to form a composite tow, and the composite tow is wound on the composite tow by using the ply network device 9. network, and successively pass through the process of the second hot roller GR2 8 and the main network (the main network device used in the main network process is 10 in the figure), and then enter the winding device 11 for winding molding to obtain POY / FDY polyester Polyester composite yarn; wherein, the output of polyester POY yarn and polyester FDY yarn is independently controlled by their respective me...

Embodiment 2

[0041] A preparation method of POY / FDY polyester composite yarn, the polyester POY yarn with a monofilament fineness of 1.2dtex goes through the processes of cooling, oiling, guide wire and pre-network successively, and the polyester FDY yarn with a monofilament fineness of 1.2dtex goes through successively After the processes of cooling, oiling, pre-internetting and the first hot roller GR1, polyester POY yarns and polyester FDY yarns are plied in the godet SR1 to form composite tows, and the composite tows are networked on the composite tows with a ply networker, and sequentially After the process of the second hot roller GR2 and the main network, it enters the winding device for winding and forming to obtain POY / FDY polyester composite filaments; wherein, the output of polyester POY filaments and polyester FDY filaments is determined by their respective melts The metering pump is controlled separately; the godet roller used in the guide wire process is set below the oiling p...

Embodiment 3

[0045] A preparation method of POY / FDY polyester composite yarn, the polyester POY yarn with a monofilament fineness of 1.2dtex goes through the processes of cooling, oiling, guide wire and pre-network successively, and the polyester FDY yarn with a monofilament fineness of 1.2dtex goes through successively After the processes of cooling, oiling, pre-internetting and the first hot roller GR1, polyester POY yarns and polyester FDY yarns are plied in the godet SR1 to form composite tows, and the composite tows are networked on the composite tows with a ply networker, and sequentially After the process of the second hot roller GR2 and the main network, it enters the winding device for winding and forming to obtain POY / FDY polyester composite filaments; wherein, the output of polyester POY filaments and polyester FDY filaments is determined by their respective melts The metering pump is controlled separately; the godet roller used in the guide wire process is set below the oiling p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com