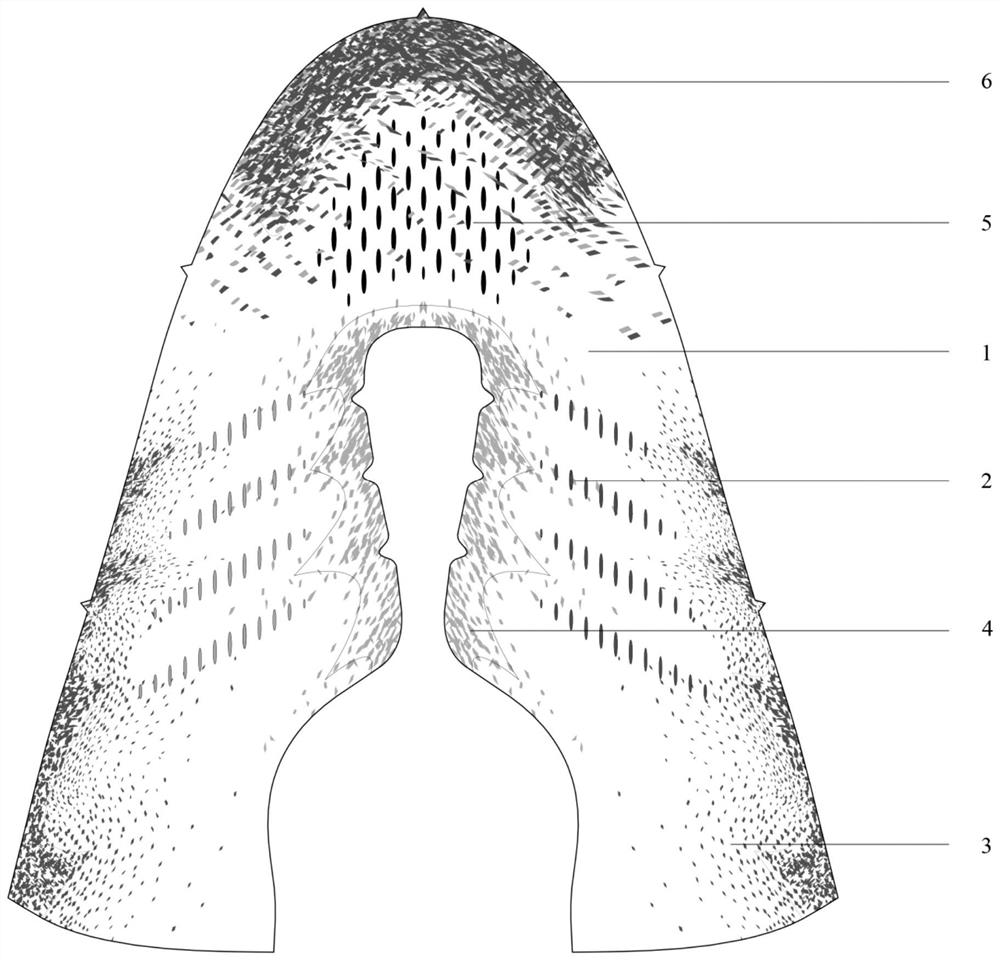

Four-color three-jacquard three-dimensional breathable warp-knitted two-needle bed vamp knitted fabric

A knitted fabric and double-needle bed technology, which is applied in warp knitting, knitting, footwear, etc., can solve the problems of jacquard weave and single color, etc., and achieve the effect of increasing the sense of shoe upper design, excellent three-dimensional effect, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

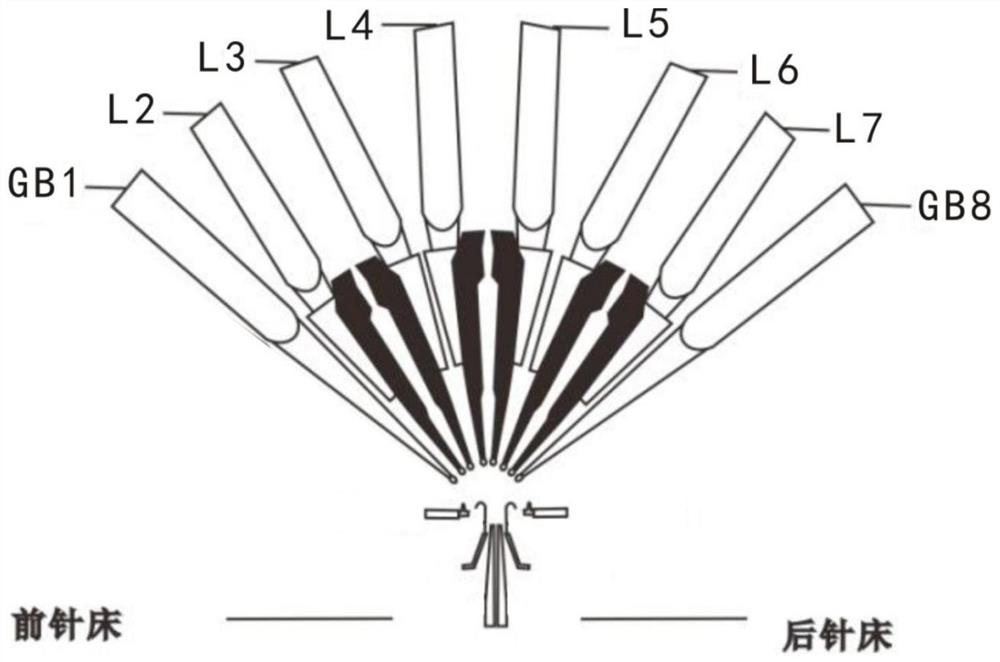

[0025] The four-color three-jacquard three-dimensional air-permeable double-needle-bar warp-knitted shoe upper fabric described in this embodiment is woven by a GE296 double-needle-bar warp knitting machine. The weaving equipment has 3 jacquard combs, 2 ground combs, and 8 traverse working lines. Adopt full-through weaving, the gauge is E22 (ie 22 needles / inch), and the knitting density is 13wpc (ie 13 wales / cm).

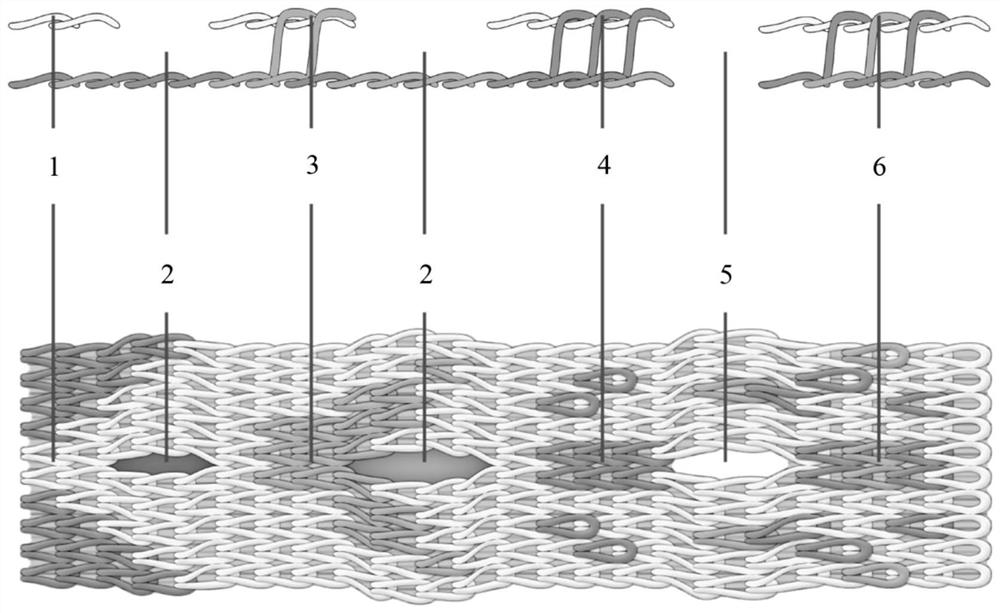

[0026] Specifically, the ground comb weave of the body, the lapping yarn number and the Jacquard basic weave are respectively:

[0027] Ground comb GB1: 0-1-1-1 / 1-0-0-0 / /

[0028] Jacquard Comb L2: 0-1-1-1 / 2-1-1-1 / /

[0029] Jacquard Comb L3: 0-1-1-1 / 2-1-1-1 / /

[0030] Jacquard Comb L4: 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com