Cable cover surface heat flux density and pressure measuring device and application method thereof

A heat flux density and measuring device technology, applied in measuring devices, force/torque/power measuring instruments, measuring heat, etc., to achieve the effects of wide measurement range, simple installation and disassembly, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

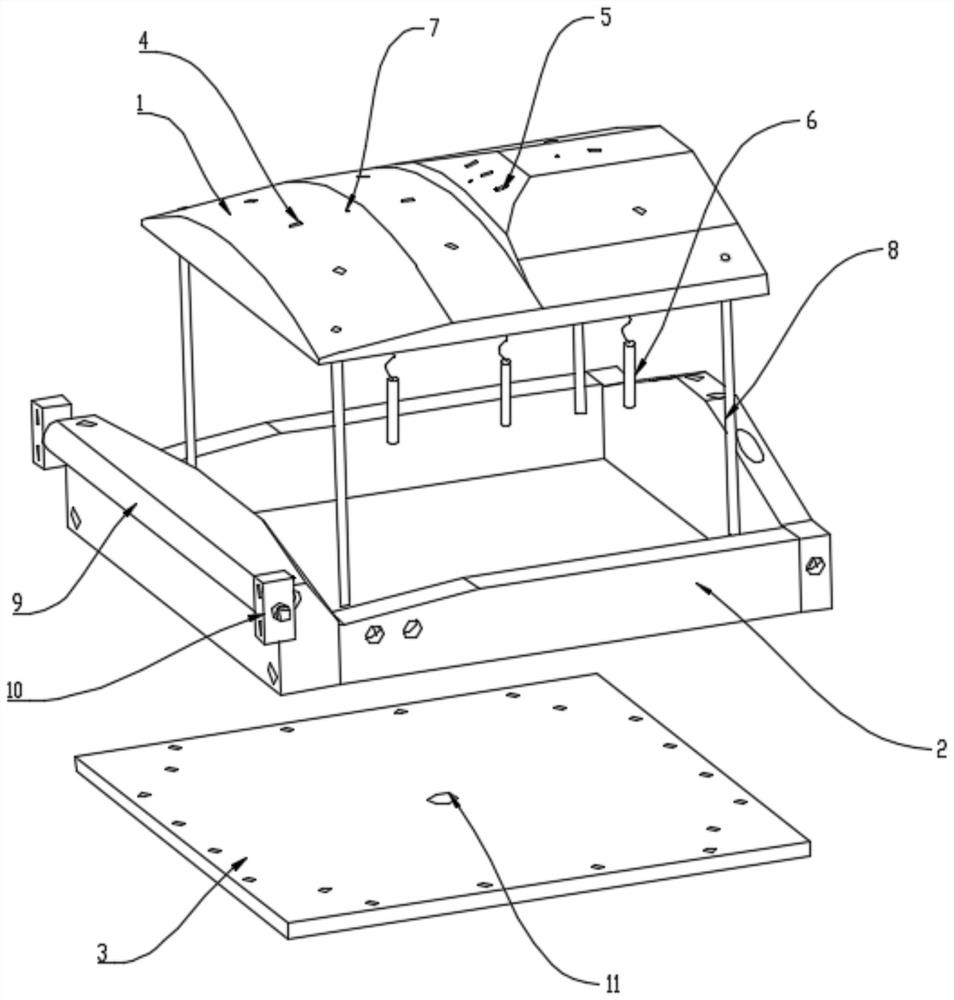

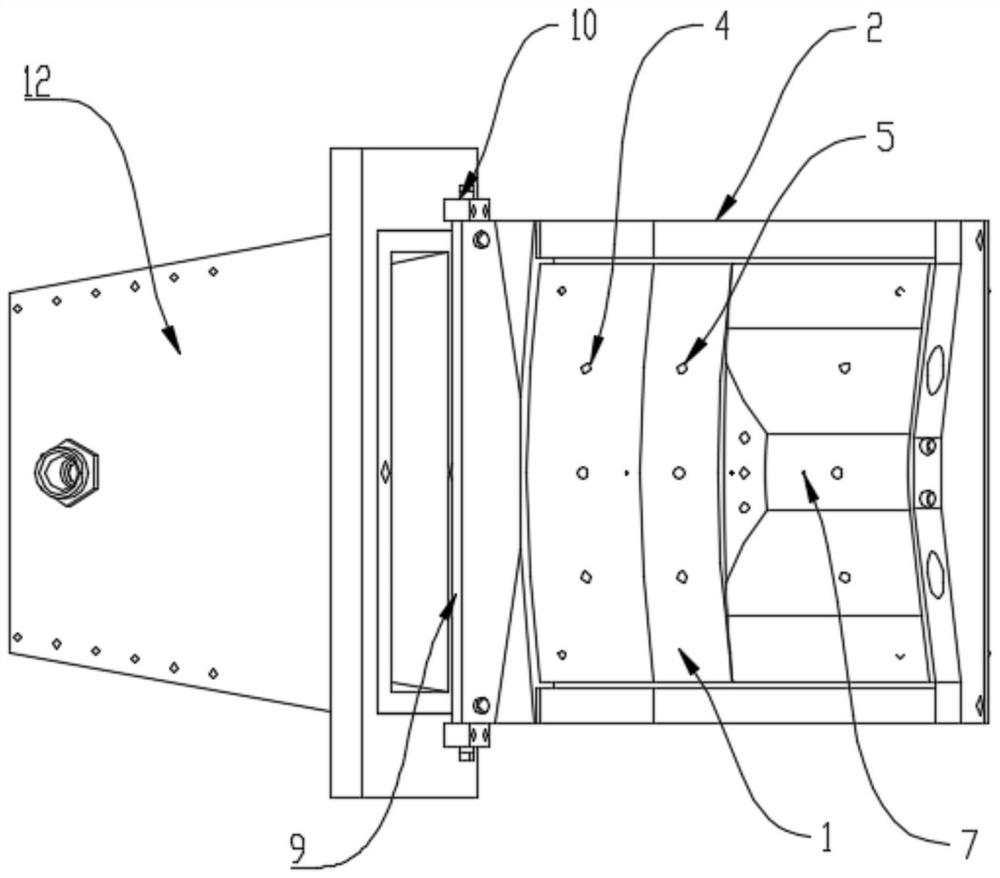

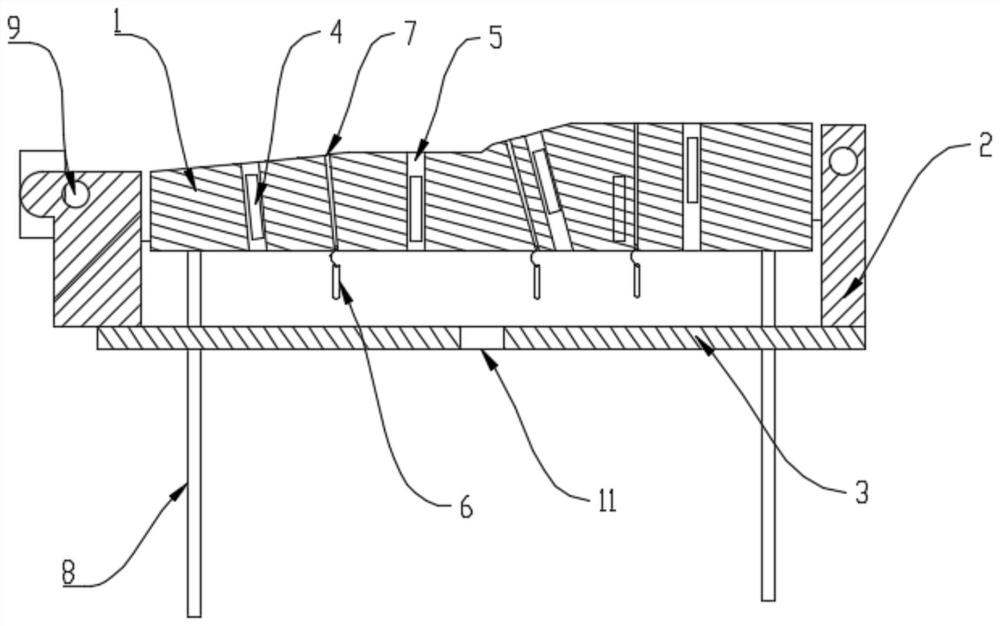

[0032] like figure 1 and figure 2 As shown, a device for measuring heat flux density and pressure on the surface of a cable cover includes an arc-shaped raised probe 1, a bracket 2 and a bottom plate 3; the arc-shaped raised probe 1, the bracket 2, and the bottom plate 3 are sequentially connected to form an airtight casing;

[0033] The arc surface on the upper surface of the arc convex probe 1 is consistent with the arc surface of the aircraft on which the cable cover is installed; the arc convex probe 1 has a plurality of connection holes, and the connection holes include a plurality of heat flow measurement holes for installing the heat flow sensor 4 5 and a plurality of pressure measuring holes 7 for connecting the pressure sensor 6.

[0034] The bracket 2 is fixedly installed on the external nozzle pipe so that the airflow direction of the nozzle pipe is parallel to the upper surface of the raised probe 1 on the arc surface; the bottom plate 3 is provided with wiring h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com