Photochromic lens and manufacturing method thereof

A technology of photochromic and photochromic lenses, which is applied in the field of lenses, can solve problems such as potential safety hazards, low light transmittance of lenses, and influence of drivers' vision, and achieve the effect of easy disassembly and reduction of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

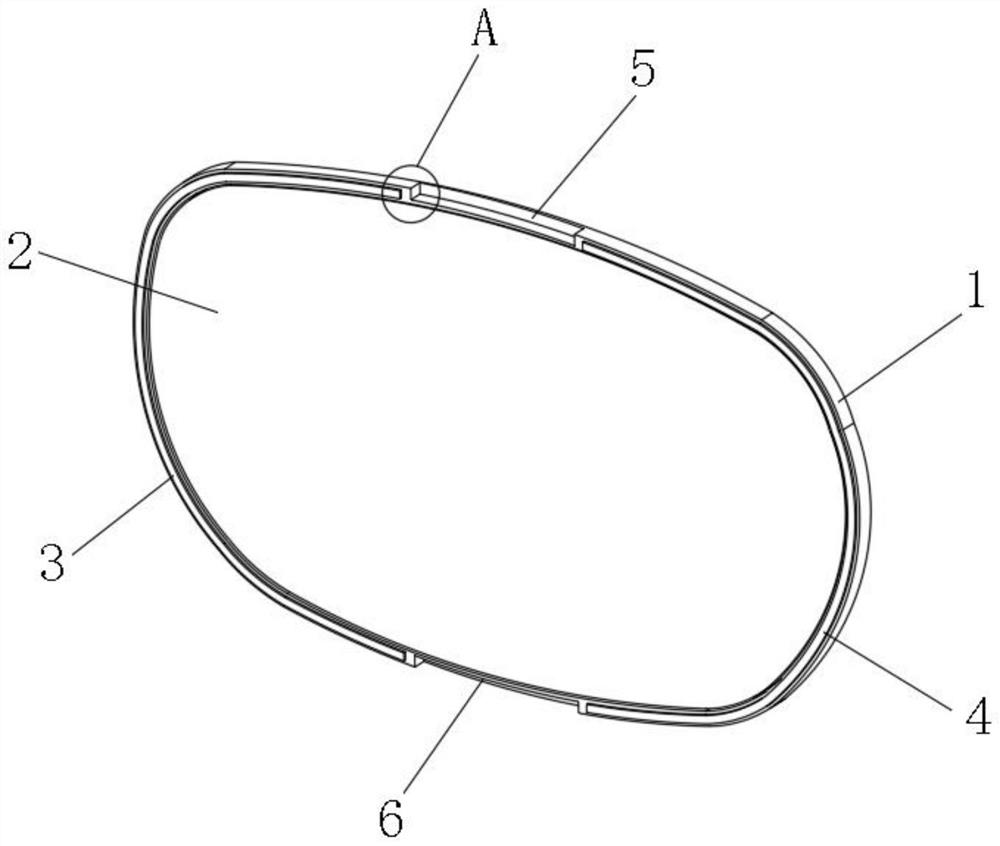

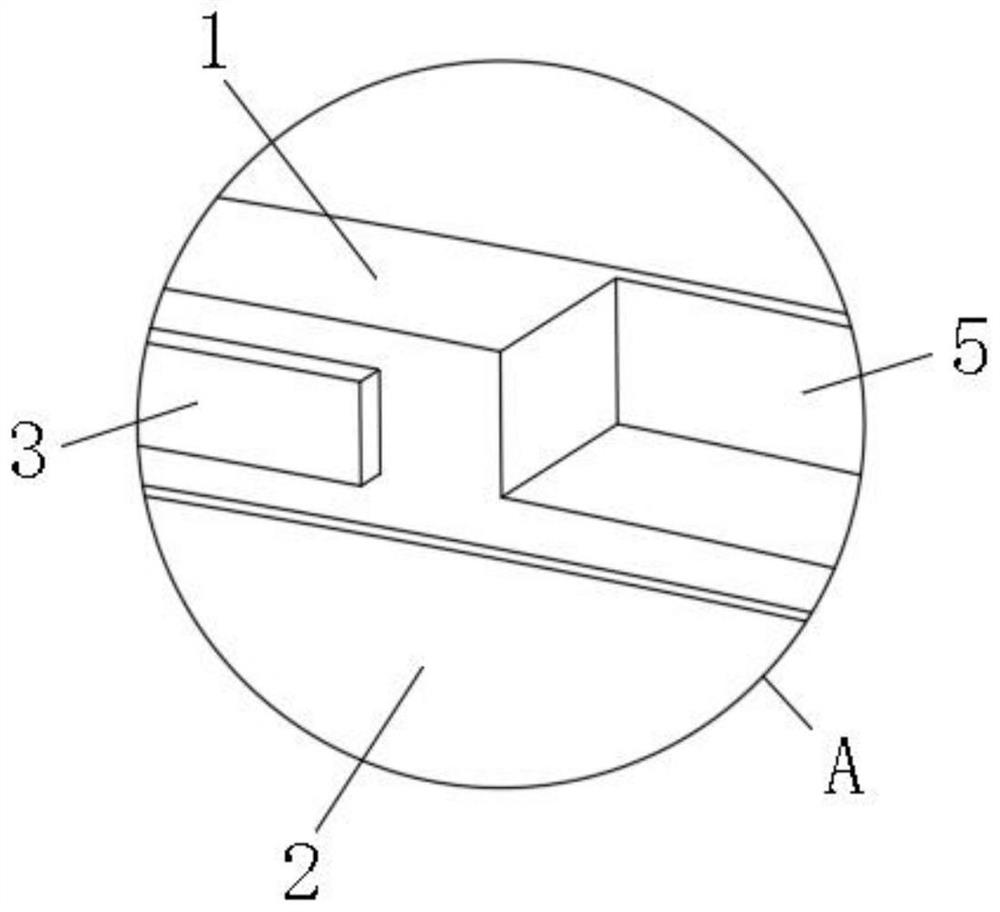

[0035] like Figure 1-3 As shown, the embodiment of the present invention provides a photochromic lens, which includes a photochromic lens body 2 installed in the center of the lens frame 1, and the photochromic lens body 2 is fitted and fixed to the inner wall of the lens frame 1, which can not only realize a tight connection and fixation , it can also be quickly replaced when the photochromic lens body 2 is broken or damaged; the photochromic lens body 2 is a flat lens, by using a flat lens, it will not affect the function and characteristics of normal glasses, but also can play a normal color changing effect;

[0036] The two sides of the inner surface of the lens frame 1 are respectively provided with a first magnetic strip 3 and a second magnetic strip 4; the first magnetic strip 3 and the second magnetic strip 4 are bonded and fixed with the lens frame 1, and the first magnetic strip The strip 3 and the second magnetic strip 4 are fixed on the inner side of the lens fram...

Embodiment 2

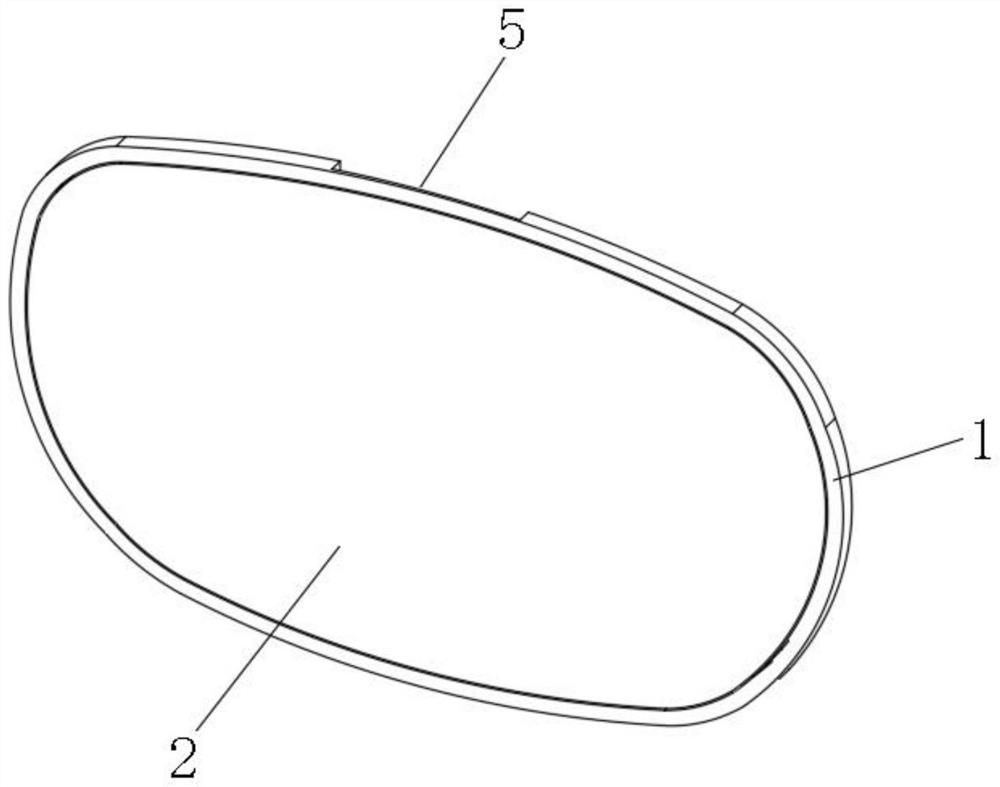

[0045] like Figure 4 As shown, this embodiment is based on the first embodiment: the lens frame 1 is made of a magnetic metal material, and the photochromic lens body 2 is fitted and fixed to the inner wall of the lens frame 1. When in use, it can be directly adsorbed and positioned on the metal frame. .

[0046] The specific steps of the production method of the photochromic lens are as follows:

[0047] S201. According to the size and structure of the mirror frame, use a casting mold and a magnetic metal material to cast a magnetic lens frame 1, remove surface burrs and excess waste after demolding, and polish the surface of the lens frame 1;

[0048] S202. Cut the photochromic lens raw material into the photochromic lens body 2;

[0049]S203. Fit the photochromic lens body 2 after cutting in S202 to the inner wall of the lens frame 1 in S201.

Embodiment 3

[0051] like Figure 5 As shown, this embodiment is based on the first embodiment: the center of the top of the lens frame 1 is fixedly connected with a positioning cover plate 7, the positioning cover plate 7 is a detachable structure, the upper frame is made of plastic material, and the lower frame is made of metal material By fixing and connecting the positioning cover 7 at the center of the top of the lens frame 1, the upper part of the lens can be hung on the top of the plastic frame, while the middle and lower parts of the lens are still attached to the metal frame.

[0052] The specific steps of the production method of the photochromic lens are as follows:

[0053] S301. According to the size and structure of the mirror frame, design a corresponding casting mold, use the casting mold to cast the lens frame 1, remove the surface burrs and excess waste after demolding, and polish the surface of the lens frame 1;

[0054] S302. Cut the photochromic lens raw material into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com