Radioactive waste liquid glass curing method

A radioactive waste liquid and vitrification technology, applied in radioactive purification, nuclear engineering, etc., can solve the problems of economic feasibility, limited application of operability, high investment in vitrification technology equipment, restrictions on radioactive waste vitrification, etc., and achieve high application Prospects and socio-economic benefits, low-temperature safe and efficient vitrification treatment, and the effect of strong operability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

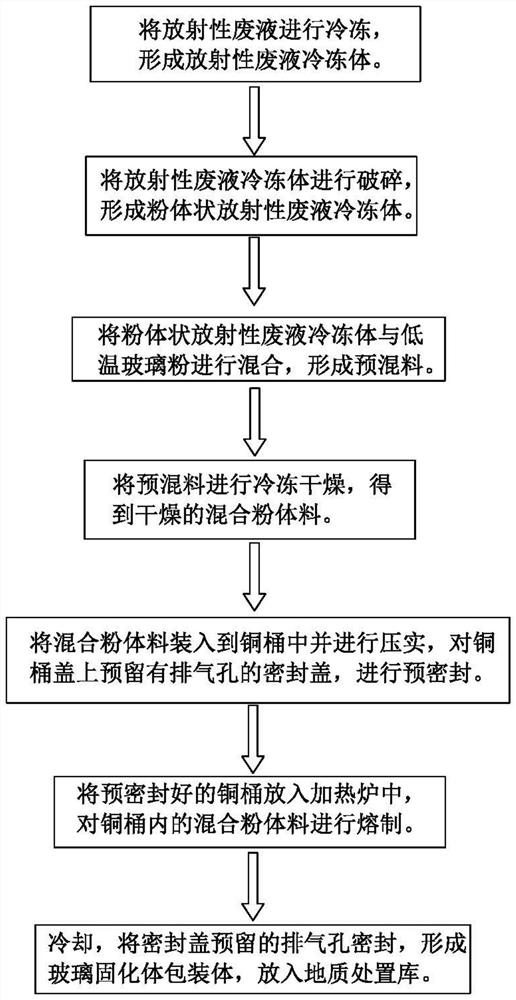

[0050] A method for vitrification of radioactive waste liquid, comprising the steps of:

[0051] S1. Freezing of radioactive waste liquid: After stirring the formed radioactive waste liquid evenly, it is frozen in a low temperature environment of -10°C to form a radioactive waste liquid frozen body;

[0052] S2. Frozen body crushing: the radioactive waste liquid frozen body formed in step S1 is crushed in a low temperature environment of 0° C., and crushed into a powder with a particle size ranging from 1 to 100 μm to form a powdery radioactive waste liquid frozen body;

[0053] S3. Mixing materials: mixing the powdery frozen radioactive waste liquid formed in step S2 with low-temperature glass frit (melting point is 300° C.) to obtain a premixed material;

[0054] S4. freeze-drying: the premix obtained in step S3 is 0.1~1×10 -3 Under Pa vacuum environment, first dry at below 0°C for about 10h, then control the temperature at 80°C, and continue drying for 10h to obtain a dry ...

Embodiment 2

[0059] A method for vitrification of radioactive waste liquid, comprising the steps of:

[0060] S1. Freezing of radioactive waste liquid: After stirring the formed radioactive waste liquid evenly, it is frozen at a low temperature of 0°C to form a radioactive waste liquid frozen body;

[0061] S2. Frozen body crushing: crush the radioactive waste liquid frozen body formed in step S1 at a low temperature of -10°C, and crush it into a powder with a particle size ranging from 1 to 100um to form a powdery radioactive waste liquid frozen body ;

[0062] S3. Mixing materials: mixing the powdery frozen radioactive waste liquid formed in step S2 with low-temperature glass frit (melting point is 600° C.) to obtain a premixed material;

[0063] S4. freeze-drying: the premix obtained in step S3 is 0.1~1×10 -3 Under a Pa vacuum environment, first dry at a temperature below 0°C for about 10 hours, then control the temperature at 30°C, and continue drying for 20 hours to obtain a dry mix...

Embodiment 3

[0068] A method for vitrification of radioactive waste liquid, comprising the steps of:

[0069] S1. Freezing of radioactive waste liquid: After stirring the formed radioactive waste liquid evenly, it is frozen in a low temperature environment of -5°C to form a frozen body of radioactive waste liquid;

[0070] S2. Frozen body crushing: crush the radioactive waste liquid frozen body formed in step S1 at a low temperature of -5°C, and crush it into a powder with a particle size ranging from 1 to 100um to form a powdery radioactive waste liquid frozen body ;

[0071] S3. Mixing materials: mixing the powdery frozen radioactive waste liquid formed in step S2 with low-temperature glass frit (melting point is 450° C.) to obtain a premixed material;

[0072] S4. freeze-drying: the premix obtained in step S3 is 0.1~1×10 -3 Under a Pa vacuum environment, first dry at a temperature below 0°C for about 10 hours, then control the temperature at 55°C, and continue drying for 15 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com