Swivel structure mass balance automatic adjusting system and application thereof

An automatic adjustment and structural quality technology, applied in the direction of measuring devices, erecting/assembling bridges, instruments, etc., can solve problems such as high labor intensity, long weighing cycle, and cumbersome weighing process, so as to improve safety and stability, Save construction time and cost, and the weighing process is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with the examples, but it should not be interpreted as a limitation of the present invention. The protection scope of the present invention is based on the contents recorded in the claims. protection scope of the present invention.

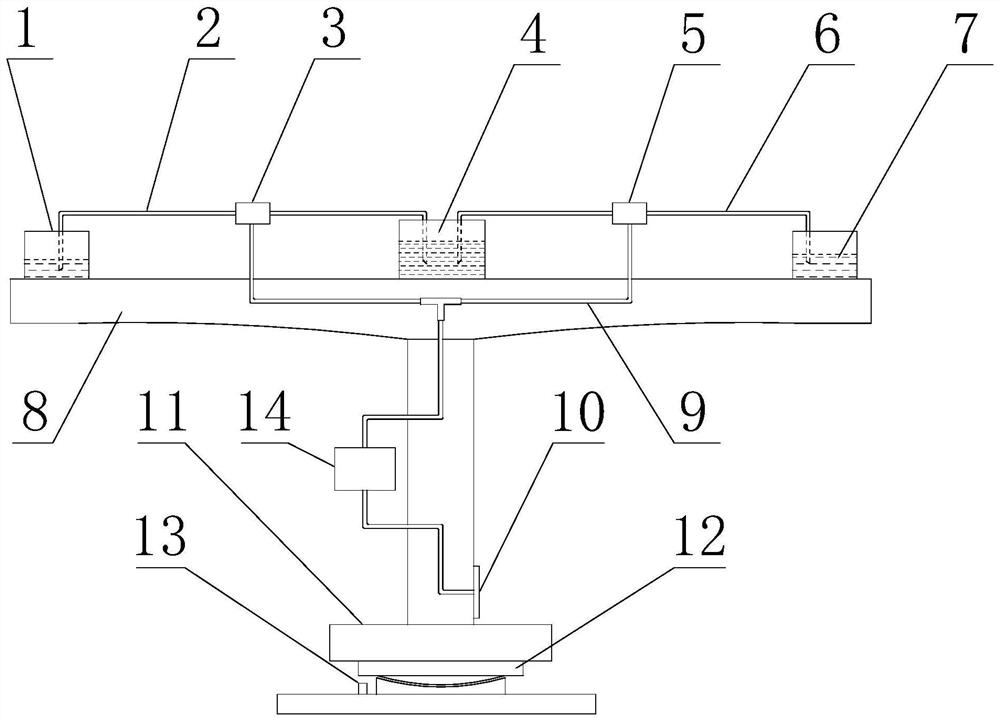

[0077] The overall concept of the maintenance system in this embodiment is as shown in the figure, and the automatic adjustment system for the mass balance of the swivel structure includes an action actuator and a control mechanism, wherein:

[0078] The action actuator includes a water supply tank 4 arranged on the swivel structure 8, a first counterweight water tank 1 and a second counterweight water tank 7 respectively arranged at both ends of the swivel structure 8, the first counterweight water tank 1 and the second counterweight The water tank 7 communicates with the water supply tank 4 through a pipeline and a high-pressure pump respectively;

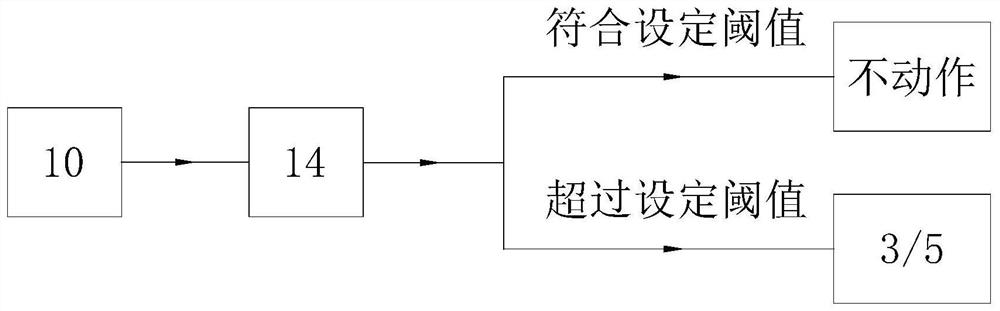

[0079] The control m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com