CTC battery system pressure detection device and use method thereof

A battery system and detection device technology, which is applied to electromagnetic measuring devices, measuring devices, testing electrical devices in transportation, etc., can solve the problem of reduced insulation resistance of the whole vehicle, reduced creepage distance and electrical gap, and battery cell leakage and other issues to achieve the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

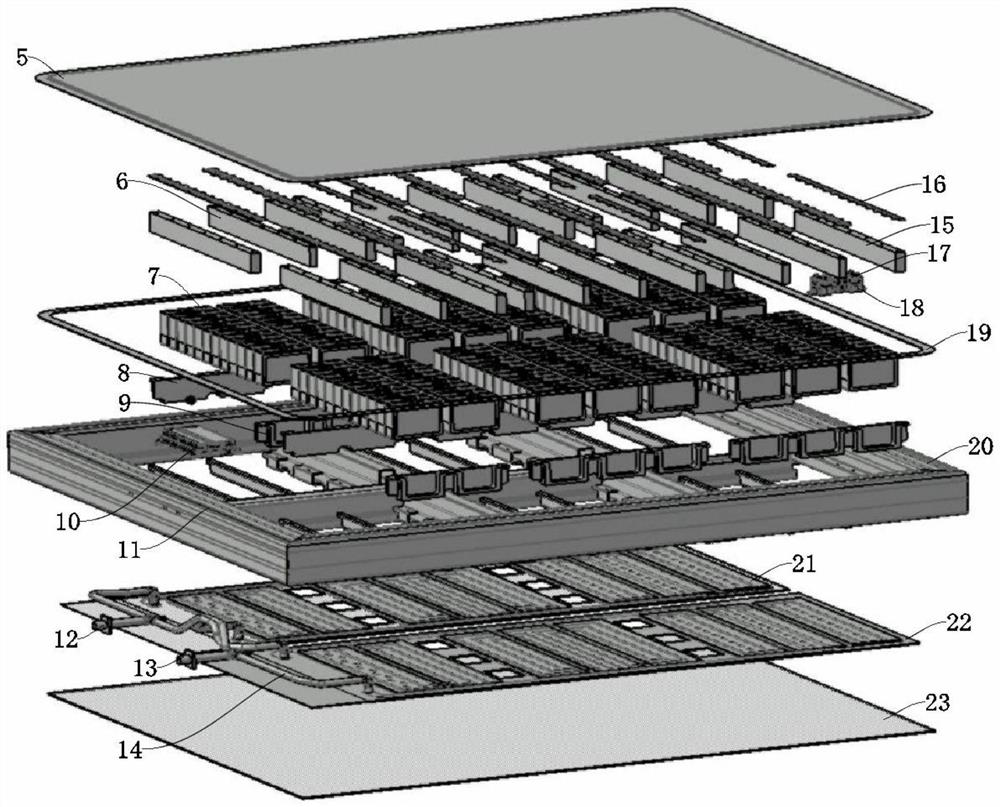

[0034] Example 1, reference Figure 1-5 : A CTC battery system pressure detecting device, including:

[0035] The upper cover 5 is provided at the bottom;

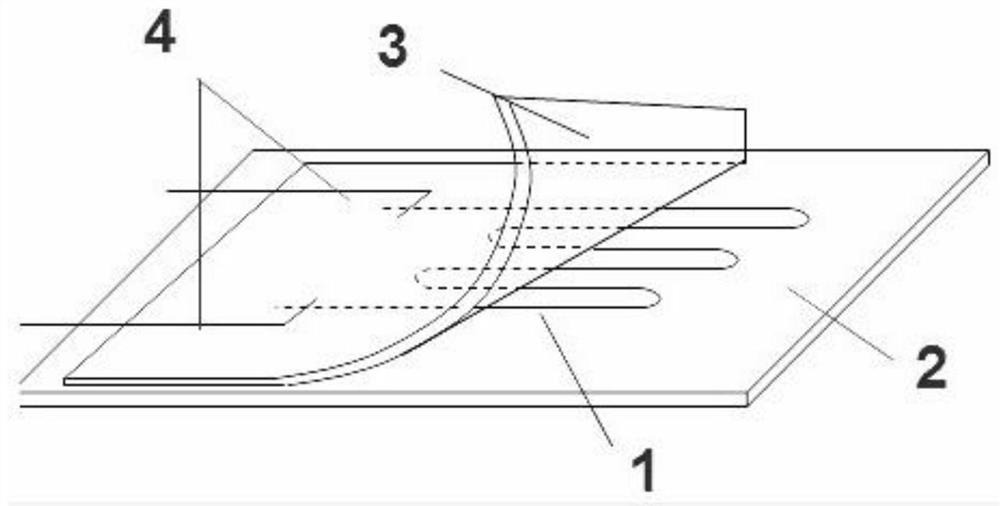

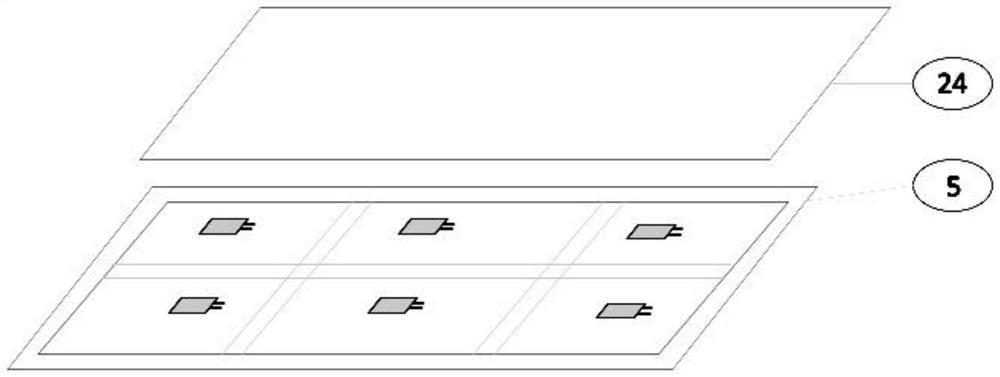

[0036] The strain sheet mechanism is provided with a plurality of groups, and the multi-group strain chip mechanism is uniformly mounted on the upper cover 5, wherein each group of strain chip mechanisms comprise a radial wire sensitive gate 1, a substrate 2, a cover layer 3, two The lead 4 and the mica plate 24, the substrate 2 mounted to the upper surface of the upper cover 5, and the resistor wire sensitive gate 1 is mounted at the upper surface of the substrate 2, and the cover layer 3 is mounted on the upper surface of the substrate 2. The two leads 4 are respectively disposed at both ends of the resistance wire sensitive gate 1, and the mica plate 24 is mounted on the upper surface of the upper cover 5;

[0037] The cooling mechanism is provided on the bottom plate 23, and the heat dissipation cooling of the CTC battery i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com