A dynamic and synchronous berth planning method for an automated terminal with side-by-side loading and unloading

An automated terminal and berth technology, which is applied in the field of dynamic synchronous berth planning of an automated terminal loading and unloading along the shore, can solve the problem that the loading and unloading transportation capacity of a container terminal cannot meet the requirements of large-scale and short-term container import and export operations, and the berth operation plan is not considered. Coordinated scheduling with operating equipment, inability to move or equip on demand, etc., to reduce the time for mobile layout of locked stations, improve the utilization rate of berths, and improve the ability of rapid operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

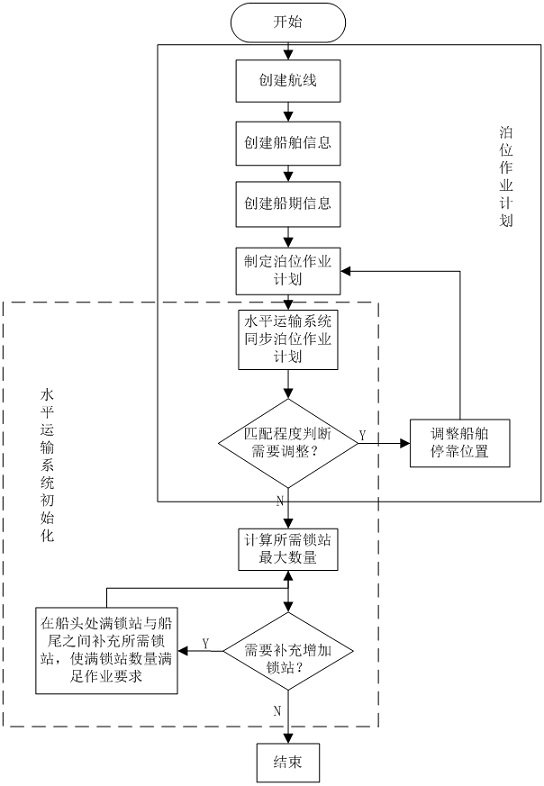

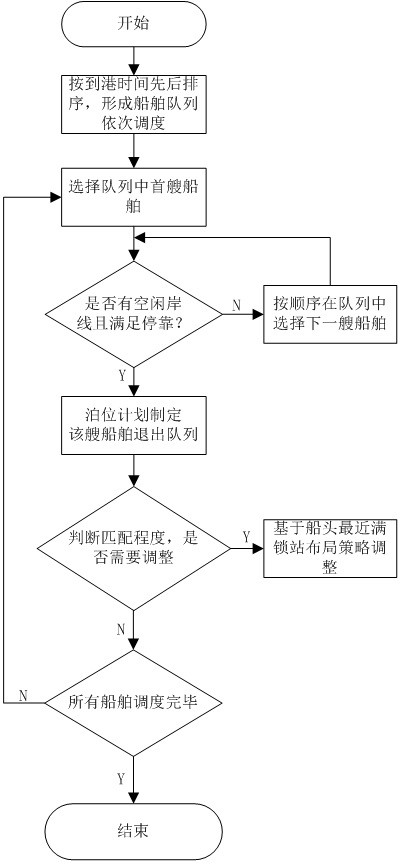

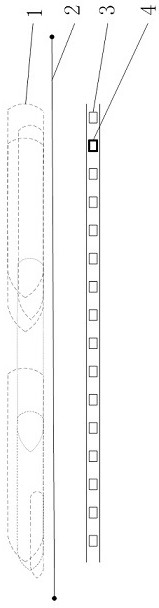

[0034] The invention selects a planned berth for the ship based on the FCFS (first come first service) berth allocation strategy of dynamic lock station configuration, and then perfects the berth operation plan based on the layout strategy of the nearest full lock station at the bow. The ship entry schedule in the berth operation plan includes the initial berthing time of container ships in the coming week, the ship operation sequence, etc., to provide a detailed berth operation sequence for the horizontal transportation system and coordinate the horizontal transportation system. The horizontal transportation system arranges the lock station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com