Method and system for identifying reading of pointer instrument in inspection scene

A technology of meter reading and digital recognition, applied in the field of intelligent robots, can solve problems such as difficult requirements, difficult to effectively identify, and poor practical application, and achieve the effect of ensuring the success rate and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

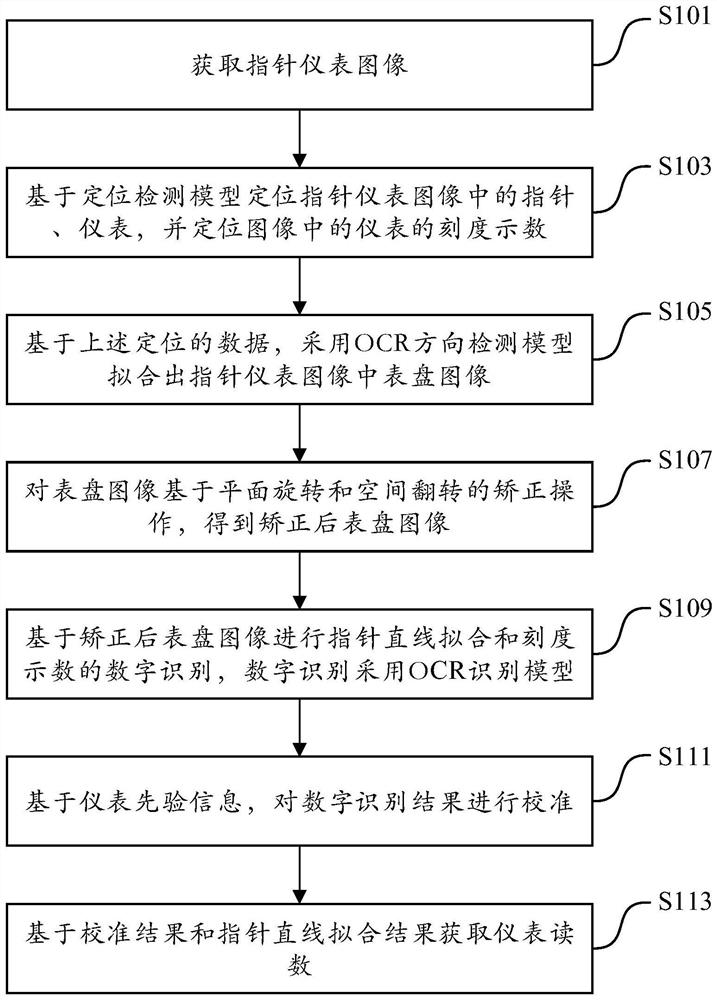

[0063] Such as figure 1 As shown, the embodiment of the present invention provides a method for identifying pointer instrument readings in an inspection scene, including the following steps:

[0064] Step S101, acquiring the pointer instrument image;

[0065] Step S103, locating pointers and meters in the pointer meter image based on the positioning detection model, and locating the scale indication of the meter in the image;

[0066] Step S105, based on the above positioning data, use the OCR direction detection model to fit the dial image in the pointer instrument image; wherein, the position detection model and the OCR direction detection model are trained by using N sample images with target instruments collected in history;

[0067] Step S107, correcting the dial image based on plane rotation and space flipping to obtain the corrected dial image; specifically, it may include:

[0068] Obtain the horizontal rotation direction of the scale indication based on the OCR dire...

Embodiment 2

[0086] On the basis of the foregoing embodiments, this embodiment may also include the following:

[0087] The OCR direction detection model of the embodiment of the present invention is a classification model composed of a Mobilnet network. There are two types of methods in OCR recognition: one is an end-to-end learning method, and the other is a non-end-to-end method. End-to-end refers to using a network (model) to input pictures and output text recognition results. The non-end-to-end network is composed of multiple networks (models) or parts, specifically: text detection model (ie OCR detection model, output text position result), text direction detection model (ie OCR direction detection model, output text angle result), text recognition model (that is, OCR recognition model, output final text result).

[0088] The OCR direction detection model in the embodiment of the present invention refers to the text direction detection model in the above-mentioned non-end-to-end me...

Embodiment 3

[0093] On the basis of the foregoing embodiments, this embodiment may also include the following:

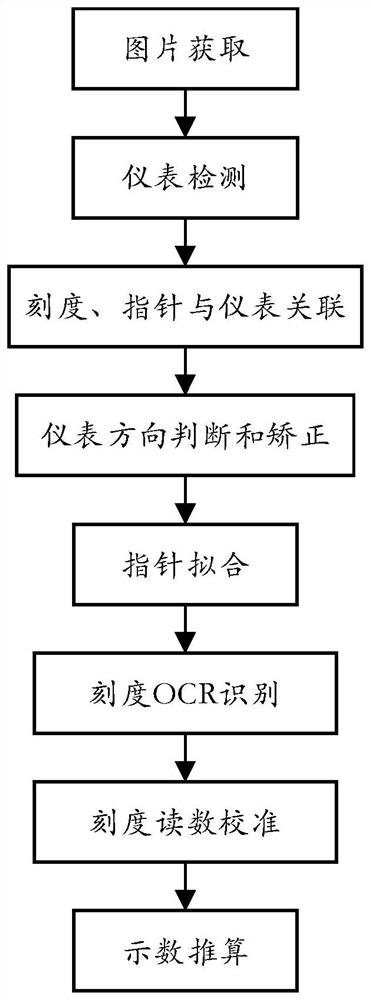

[0094] In order to facilitate the understanding of the technical solution of this embodiment, this implementation provides a method for identifying pointer instrument readings in an inspection scene in combination with actual application scenarios, so as to describe in detail, as follows figure 2 As shown, the method may include the following steps:

[0095] Step (1) image acquisition, this step is to collect N sample images with target instruments at the inspection site, obtain image data sets after labeling, and divide training sets and test sets for subsequent positioning detection models and OCR models (including OCR direction detection model and OCR recognition model) training, and algorithm testing.

[0096] Step (2) instrument detection, this step includes the detection of the surface of the instrument panel, the detection of the scale indication of the instrument and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com