Integral die forging forming method for spherical shell of manned cabin of titanium alloy bathyscaph

A technology for deep submersibles and manned cabins, applied in metal processing equipment, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc. , hardness, low wear resistance, difficulty in meeting deep-diving strength and other issues, to achieve the effect of reducing welding risk, satisfying structure and performance, and reducing overall production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

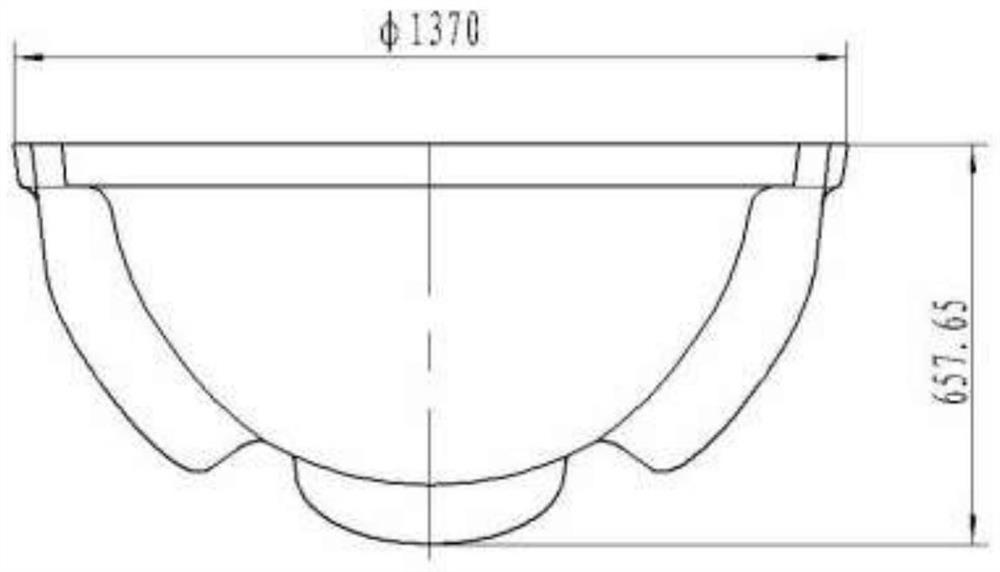

[0039] Design the forging drawing: on the basis of the part drawing, increase the machining allowance according to the shape, and the machining allowance on one side is 8mm. The design draft angle is 7°, so that the forging can be released from the mold smoothly. The outer contour size of the forging is 1370mm×1225mm×657mm, and the horizontal net projected area is 1.228m 2 , The forging weight is 890Kg.

[0040] Upsetting: Ti62A titanium alloy rod blanking, preheating the upper and lower anvils, the preheating time is 2 hours, the preheating temperature is 200°C, and the bar is heated to Tβ-(30~35°C), at Tβ-(30 ~35°C) temperature, holding time 0.8min / mm. Carry out 4-fire upsetting, the pressing amount of each fire upsetting is 40%, and the pressing speed is 20mm / s. The size of the blank after upsetting is φ1170mm×200mm, and the weight is 990Kg. When upsetting each fire, cover the upper and lower surfaces of the blank with insulation cotton to reduce the heat dissipation rat...

Embodiment 2

[0047] Design the forging drawing: on the basis of the part drawing, increase the machining allowance according to the shape, and the machining allowance on one side is 8mm. The design draft angle is 7°, so that the forging can be released from the mold smoothly. The outer contour size of the forging is 1370mm×1225mm×657mm, and the horizontal net projected area is 1.228m 2 , The forging weight is 890Kg.

[0048] Upsetting: Ti62A titanium alloy rod blanking, preheating the upper and lower anvils, the preheating time is 2 hours, the preheating temperature is 200°C, and the bar is heated to Tβ-(35~40°C), at Tβ-(35 ~40°C) temperature, holding time 0.9min / mm. Carry out 4-fire upsetting, the pressing amount of each fire upsetting is 35%, and the pressing speed is 20mm / s. The size of the blank after upsetting is φ1170mm×200mm, and the weight is 990Kg. When upsetting each fire, cover the upper and lower surfaces of the blank with insulation cotton to reduce the heat dissipation rat...

Embodiment 3

[0055] Design the forging drawing: on the basis of the part drawing, increase the machining allowance according to the shape, and the machining allowance on one side is 8mm. The design draft angle is 7°, so that the forging can be released from the mold smoothly. The outer contour size of the forging is 1370mm×1225mm×657mm, and the horizontal net projected area is 1.228m 2 , The forging weight is 890Kg.

[0056] Upsetting: Ti62A titanium alloy rod blanking, preheating the upper and lower anvils, the preheating time is 2 hours, the preheating temperature is 200°C, and the bar is heated to Tβ-(40~45°C), at Tβ-(40 ~45°C) temperature, holding time 1min / mm. Carry out 4-fire upsetting, the pressing amount of each fire upsetting is 30%, and the pressing speed is 15mm / s. The size of the blank after upsetting is φ1170mm×200mm, and the weight is 990Kg. When upsetting each fire, cover the upper and lower surfaces of the blank with insulation cotton to reduce the heat dissipation rate....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com