Platinum-rhodium alloy bushing plate

A platinum-rhodium alloy and bushing technology, applied in the field of platinum-rhodium alloy bushings, can solve problems such as cost increase, and achieve the effects of improving production efficiency, reducing production costs, and stabilizing high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

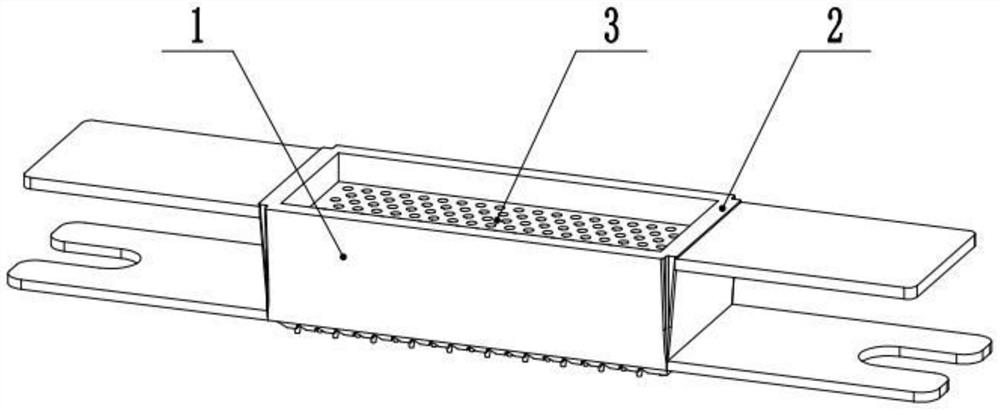

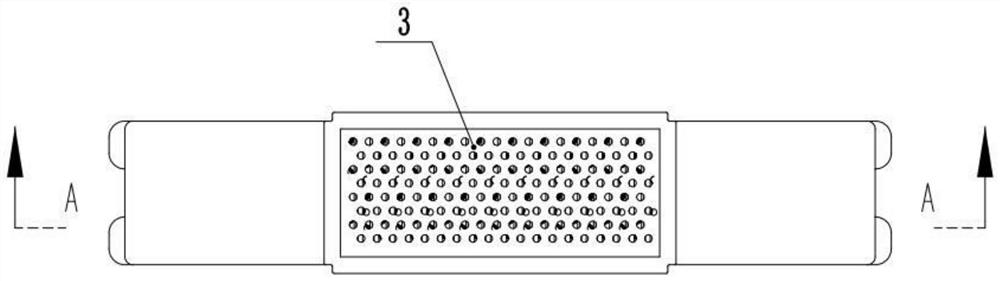

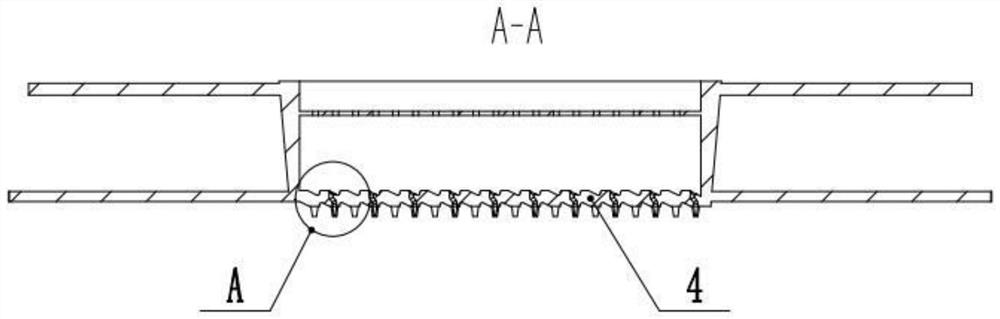

[0032] Such as figure 1 Shown in -7, a kind of platinum-rhodium alloy leak plate provided by the present invention includes a leak plate body, and the leak plate body includes a box body 1 and a screen plate 3 arranged in the box body 1, outside the box body 1 The edge is provided with flanging 2, the bottom of the box body 1 is provided with a bottom plate 4, and the bottom of the bottom plate 4 is provided with a number of nozzles 401, and the bottom plate 4 is provided with a number of channels 402 corresponding to the positions of the nozzles 401. One side of body 1 is provided with AB thermocouple wire;

[0033] The top surface of the bottom plate 4 is provided with a plurality of diversion step grooves 403, and the length direction of the diversion step grooves 403 is perpendicular to the length direction of the box body 1, and the vertical cross-sectional shape of the diversion step grooves 403 is a right triangle, And the two right-angled sides of the right-angled tri...

Embodiment 2

[0041] Such as Figure 8As shown in -10, the present embodiment is basically the same as Embodiment 1, the only difference being that a guide edge 405 is arranged on the outside of the guide port 404, and the guide edge 405 is in a vortex shape, and the pitch of the vortex line is equal to that of the guide port. 1 / 2 of the diameter of 404, the number of turns of the spiral line is 3 turns. The vertical section of the guide edge 405 is an equilateral triangle, and the length of the side of the triangle is equal to 1 / 4 of the diameter of the guide opening 404 . The purpose of setting the guide edge 405 is to make the molten glass form a small vortex at the guide port 404 and accelerate the molten glass entering the channel 402 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com