Coal face lower section gas treatment method

A technology for coal mining face and working face, which is applied in the fields of gas emission, mining equipment, earth-moving drilling, etc., can solve the problems affecting the development of the coal industry, etc., to reduce the difficulty of gas management, reduce the intake gas, and reduce the gas The effect of governance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

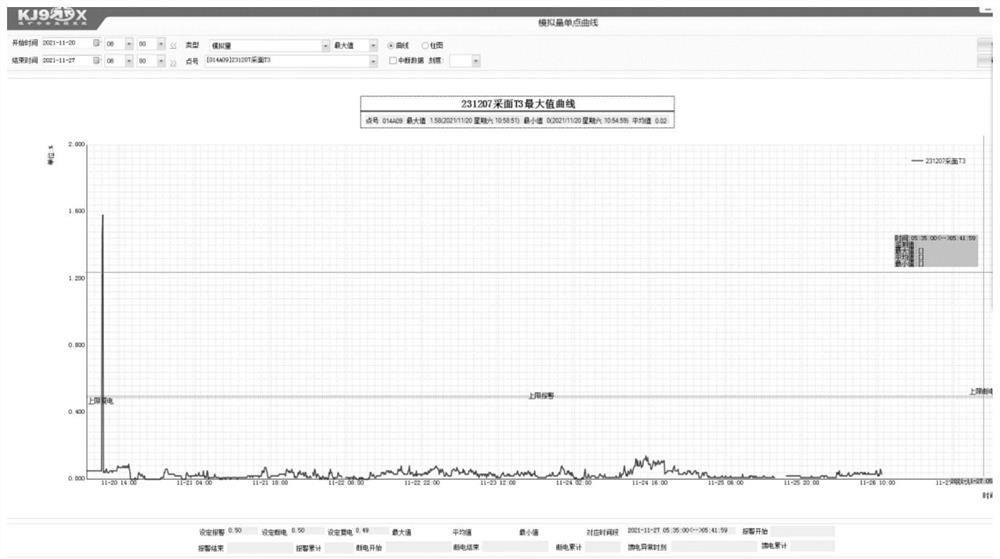

[0021] In order to ensure that the gas in the 231209 working face of the lower section will be controlled in advance, the gas control efforts in the mining working face of the lower section will be reduced. At the same time to reduce the air intake gas of the 231207 mining face, this embodiment adopts a gas control method for the section below the coal mining face. The coal seam gas in the lower section is pre-drained, and the gas in the 12# coal seam in the lower section is extracted through the long borehole in the construction section of the lower side of the 231207 roadway.

[0022] In this embodiment, further, the distance between the long boreholes in the section is 1.0 m to 3.0 m, and the diameter of the boreholes is φ94 mm.

[0023] In this embodiment, further, the end hole of the long borehole in the section is controlled along the inclination of the coal seam to 15.0m outside the contour line of the lower side of the transportation roadway in the working face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com