A method for improving the physical properties of fennel stalk flake substrate by beating enzyme treatment

A technology of physical properties and pulping enzymes, applied in the treatment of tobacco, food science, tobacco, etc., can solve the problems of wasting raw materials, occupying a lot of warehouses, and high production costs, achieving the effects of easier removal, more cross-linking points, and improved physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

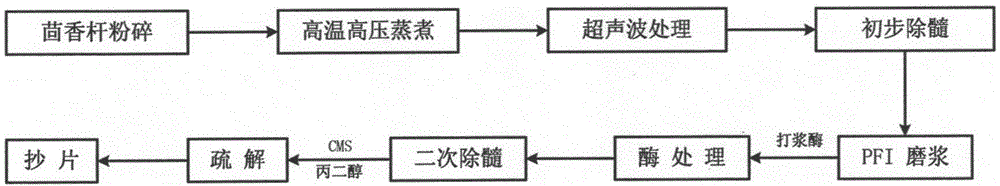

[0030] Such as figure 1 As shown, the beating enzyme treatment of the present invention improves the method for the physical properties of the fennel stalk flake substrate, specifically:

[0031] (1) After pulverizing the fennel stalks with a plant grinder, add water to prepare a mixed solution with a material-to-liquid ratio of 1:9, cook it in an electric rotary cooking pot at 120°C and 0.2MPa for 4 hours, and filter off the waste liquid. Perform ultrasonic treatment in water for 1 hour, take it out, repeatedly wash the pulp and remove pith through a 60-mesh cloth bag, and dry it with a dehydrator to balance the water to obtain the slurry;

[0032] (2) Take a certain amount of beating enzyme and prepare a 5% concentration of beating enzyme aqueous solution for subsequent use; add the enzyme solution to the slurry (containing 30 g of dry pulp), add water to prepare a slurry with a concentration of 10%, and The content of beating enzyme in the material is 0.02% of the weight o...

Embodiment 2

[0038] Such as figure 1 As shown, the beating enzyme treatment of the present invention improves the method for the physical properties of the fennel stalk flake substrate, specifically:

[0039] (1) After pulverizing the fennel stalks with a plant grinder, add water to prepare a mixed solution with a material-to-liquid ratio of 1:8, cook it in an electric rotary cooking pot at 120°C and 0.3MPa for 5 hours, and filter off the waste liquid. Perform ultrasonic treatment in water for 1.5 hours, take it out, repeatedly wash pulp and remove pith through 80-mesh cloth bag, and dry it with a dehydrator to balance the water to obtain slurry;

[0040] (2) Take a certain amount of beating enzyme and prepare a 5% concentration of beating enzyme aqueous solution for subsequent use; add the enzyme solution to the slurry (containing 30 g of dry pulp), add water to prepare a slurry with a concentration of 10%, and The content of beating enzyme in the feed is 0.03% of the weight of the dry p...

Embodiment 3

[0046] Such as figure 1 As shown, the beating enzyme treatment of the present invention improves the method for the physical properties of the fennel stalk flake substrate, specifically:

[0047] (1) After pulverizing the fennel stalks with a plant grinder, add water to prepare a mixed solution with a material-to-liquid ratio of 1:10, cook it in an electric rotary cooking pot at 140°C and 0.3MPa for 4 hours, and filter off the waste liquid. Perform ultrasonic treatment in water for 1.5 hours, take it out, repeatedly wash pulp and remove pith through 80-mesh cloth bag, and dry it with a dehydrator to balance the water to obtain slurry;

[0048] (2) Take a certain amount of beating enzyme and prepare a 5% concentration of beating enzyme aqueous solution for subsequent use; add the enzyme solution to the slurry (containing 30 g of dry pulp), add water to prepare a slurry with a concentration of 10%, and The content of beating enzyme in the feed is 0.04% of the weight of the dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com