Fabricating fault tolerant non-linear waveguide cones

A nonlinear waveguide technology, applied in the design and manufacture of tapered waveguide, heterogeneous transition field, can solve the problem of increased light propagation loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

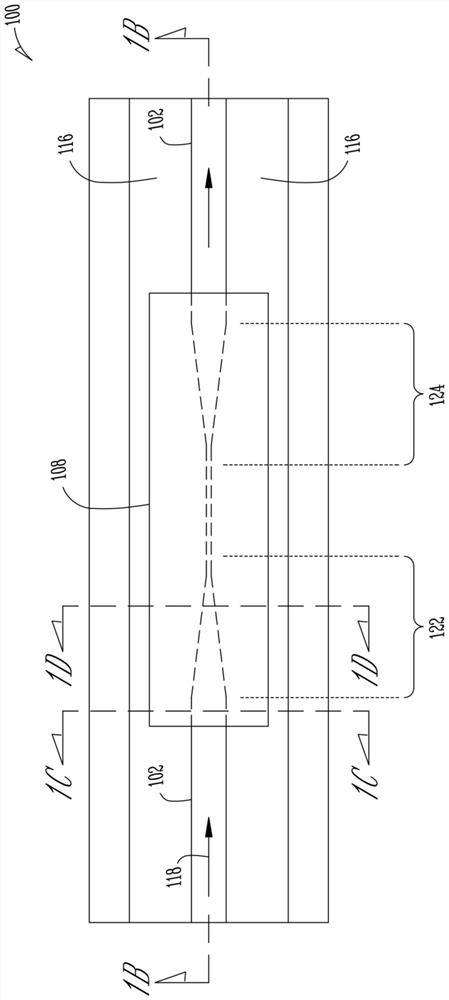

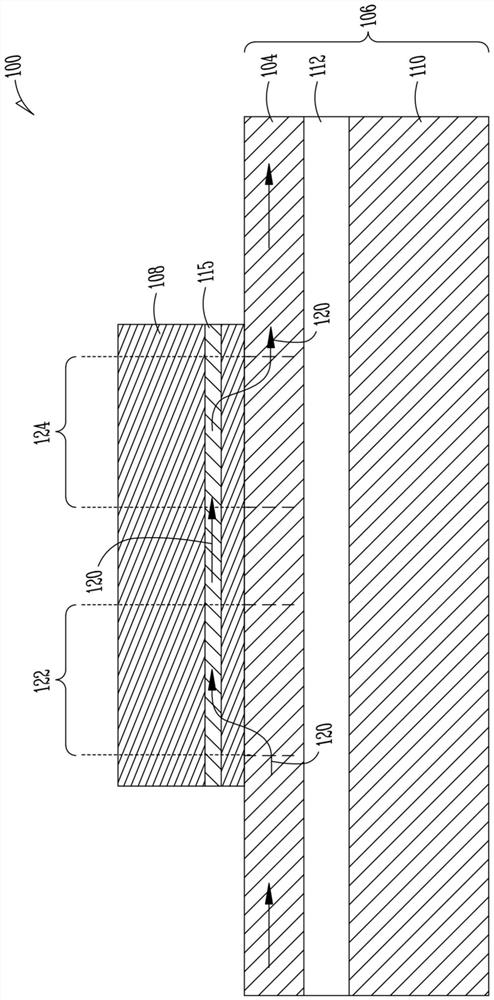

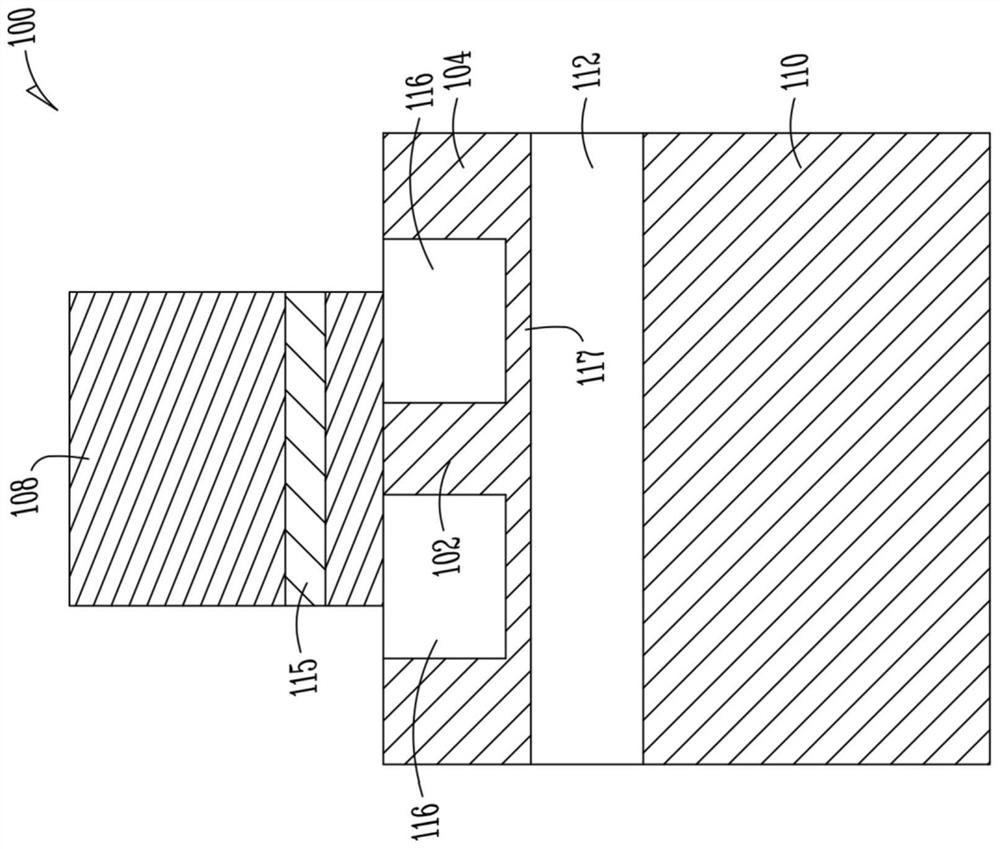

[0019] This paper describes a method for designing an optical waveguide transition with one or more nonlinear waveguide tapers that optimizes the trade-off between taper length and scattering loss. In a nonlinear waveguide cone, the cone profile (understood herein as the change in waveguide width as a function of length along the waveguide cone) is non-linear. For a given change in waveguide width with respect to a given cone length, a suitable nonlinear waveguide cone profile can achieve lower losses than a linear waveguide cone profile, or conversely, for a given limit on acceptable scattering losses, the nonlinear The waveguide cone can be designed shorter.

[0020] The precise cone profile for optimal performance depends on the scattering rate, which is a function of the waveguide width. The width-dependent scattering rate in turn depends on the design parameters of the waveguide transition, such as the fabricated dimensions (eg layer thickness) and material properties (e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com