Synchronous stripping device for multiple strands of wires and cables

A technology for multi-strand wires and cables, applied in the field of wires and cables, can solve the problems of unfavorable wire core recycling, increased processes, and inability to transmit wires of different diameters, etc., to achieve the effect of facilitating cutting processing, improving processing efficiency, and avoiding residual skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

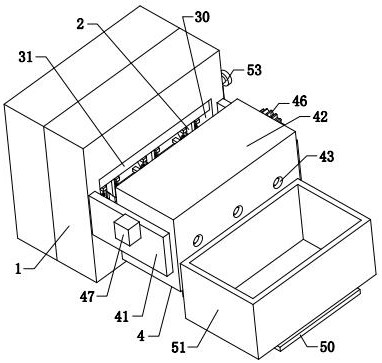

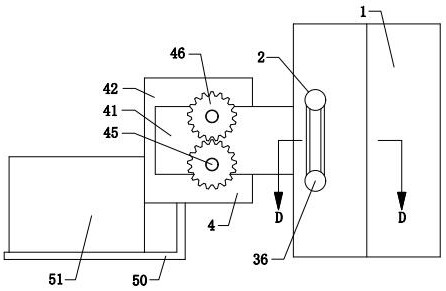

[0034] refer to figure 1 and figure 2 , a multi-strand wire and cable synchronous stripping device, comprising a processing box 1, a peeling part 2 and a wire core conveying part 4, the left end of the processing box 1 is provided with feeding ports 11 at equal intervals along its front and rear directions, and the feeding ports 11 The diameter of its left end is larger than the diameter of its central part; it is convenient to guide the electric wire 6 to be processed, and it is convenient for the electric wire 6 to be inserted into the feeding port 11; Components, the processing box 1 is provided with a peeling part 2, and the right end of the processing box 1 is equipped with a wire core delivery part 4.

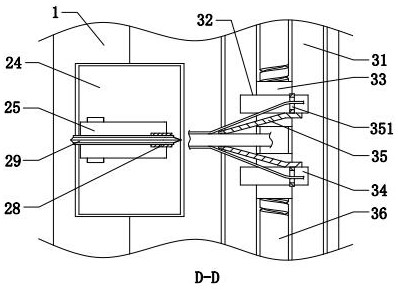

[0035] refer to image 3 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com