Material mixing machine for processing cooked beef food

A material mixer and cooked food technology, applied in mixers, mixers with rotary stirring devices, post-processing of mixtures, etc., can solve the problems of not being able to continue stirring for a long time, reducing the mixing uniformity of materials, and increasing labor intensity, etc. Achieve the effect of ensuring uniformity, improving efficiency and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

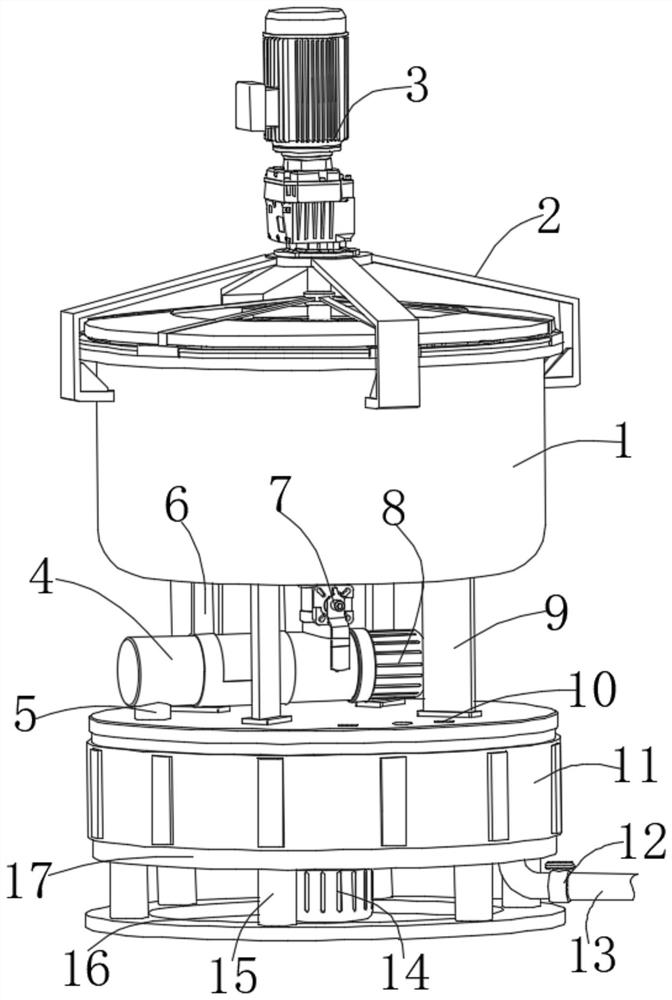

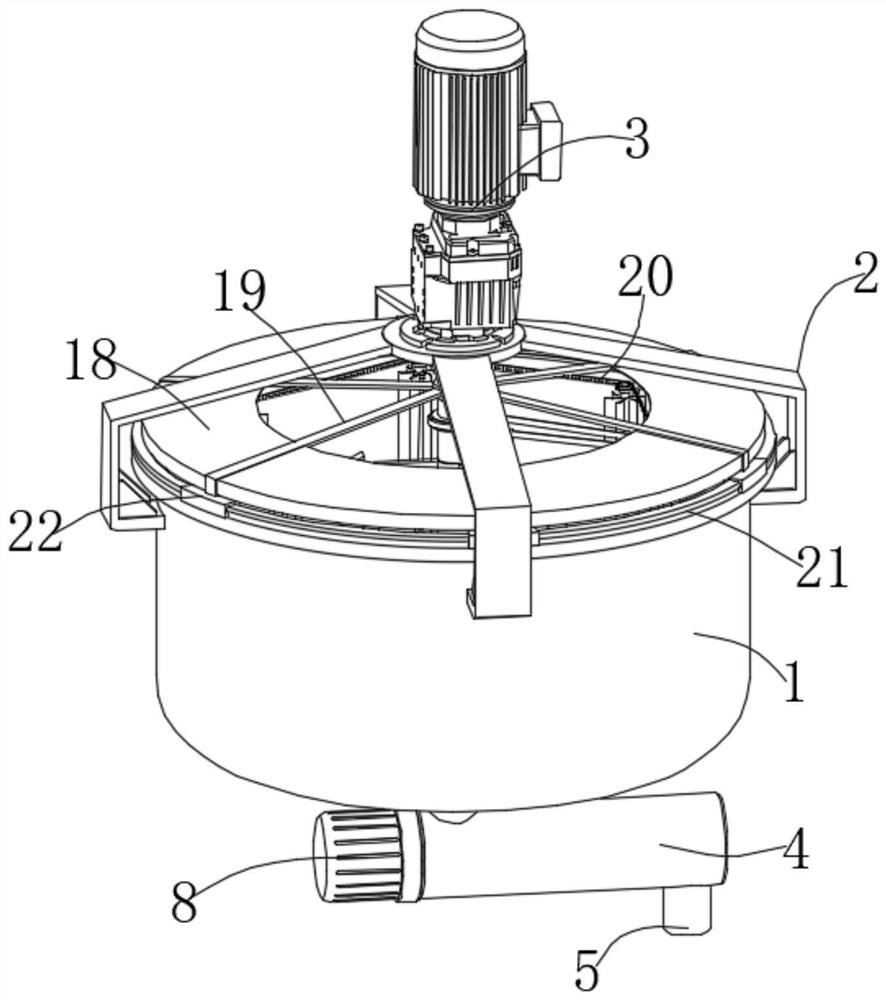

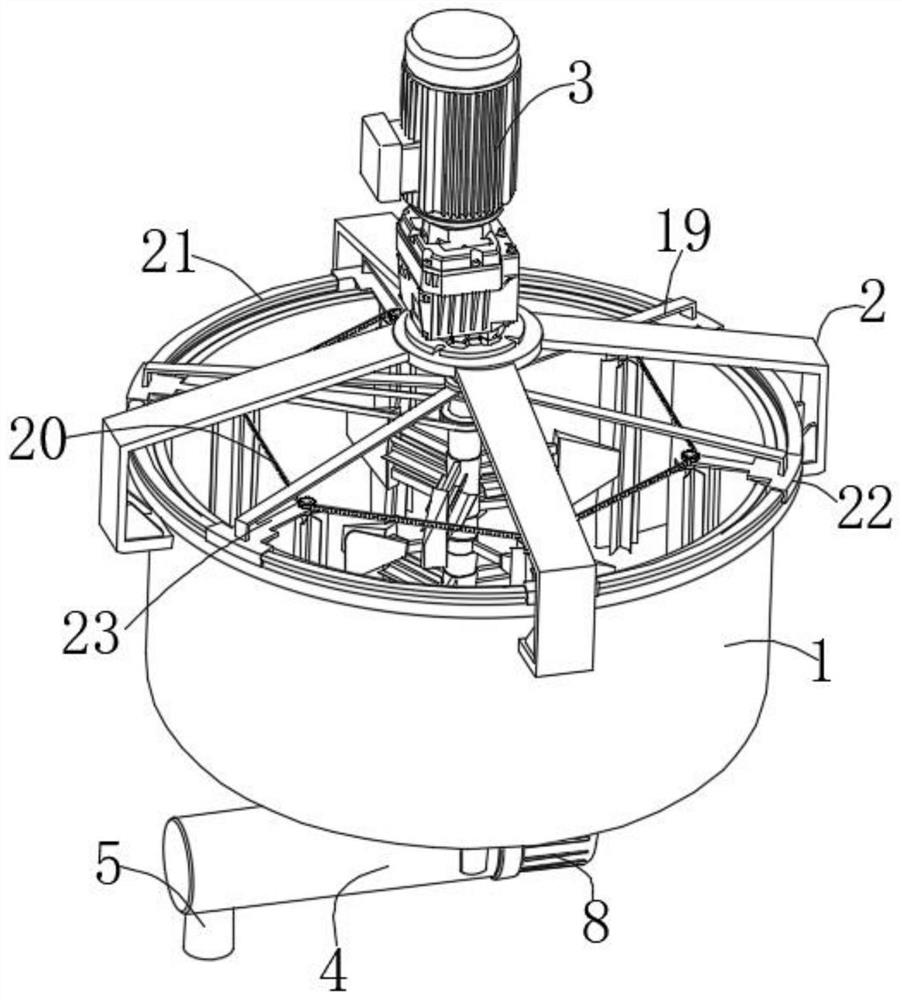

[0028] Such as Figure 1-Figure 8 The shown material mixer for beef cooked food processing includes a mixing cylinder 1 with an open top, and a mixing element is arranged inside the mixing cylinder 1, and the mixing element includes an upper motor fixed on the top of the mixing cylinder 1 through a motor frame 2 3. The output shaft of the upper motor 3 runs through the motor frame 2 and the end is vertically connected to the first drive shaft 30. The first drive shaft 30 extends to the inside of the mixing cylinder 1 and is fixedly sleeved with two second shaft sleeves 38 on the outside. A plurality of second mixing boards 36 are installed on the outside of the shaft sleeve 38 through the connecting frame 37, and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com