Embedded type hot die forging piston die

A hot die forging and mosaic technology, which is applied in the field of die forging, can solve problems such as die failure, easy cracking, and failure to increase production capacity, and achieve the effect of reducing the force on the die, reducing stress, and increasing the life of the die

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

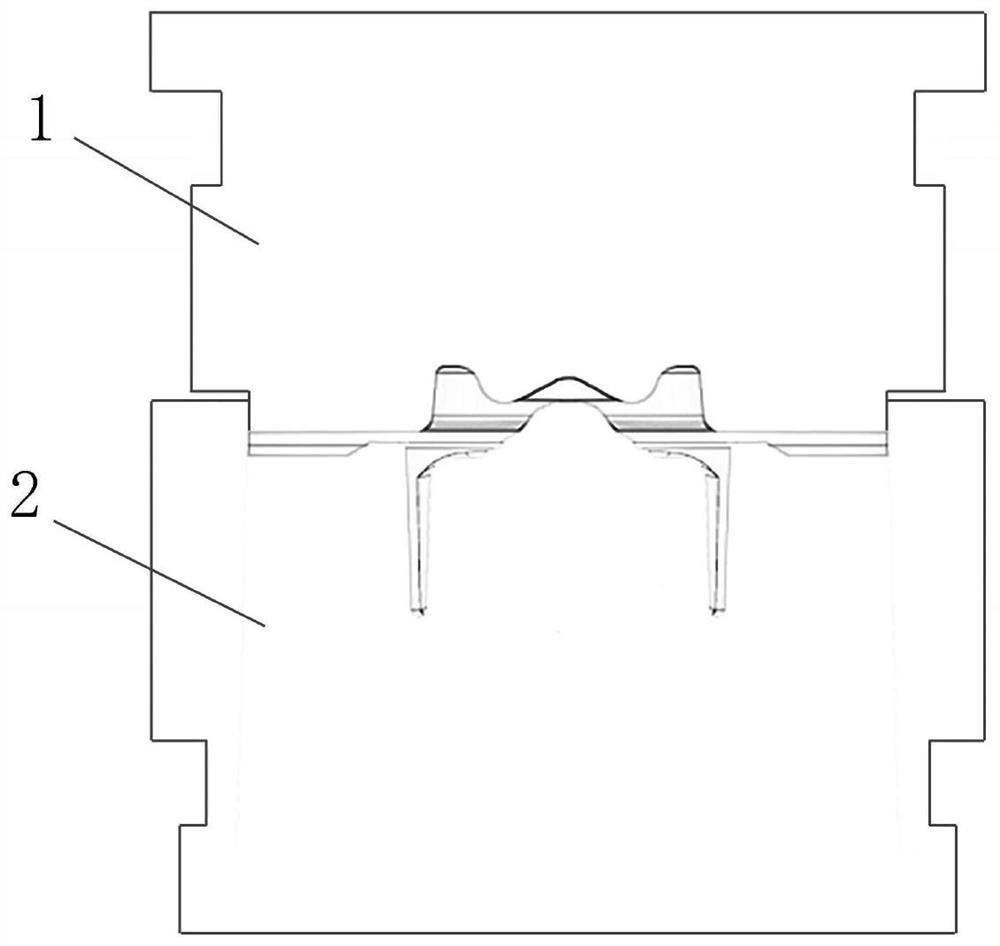

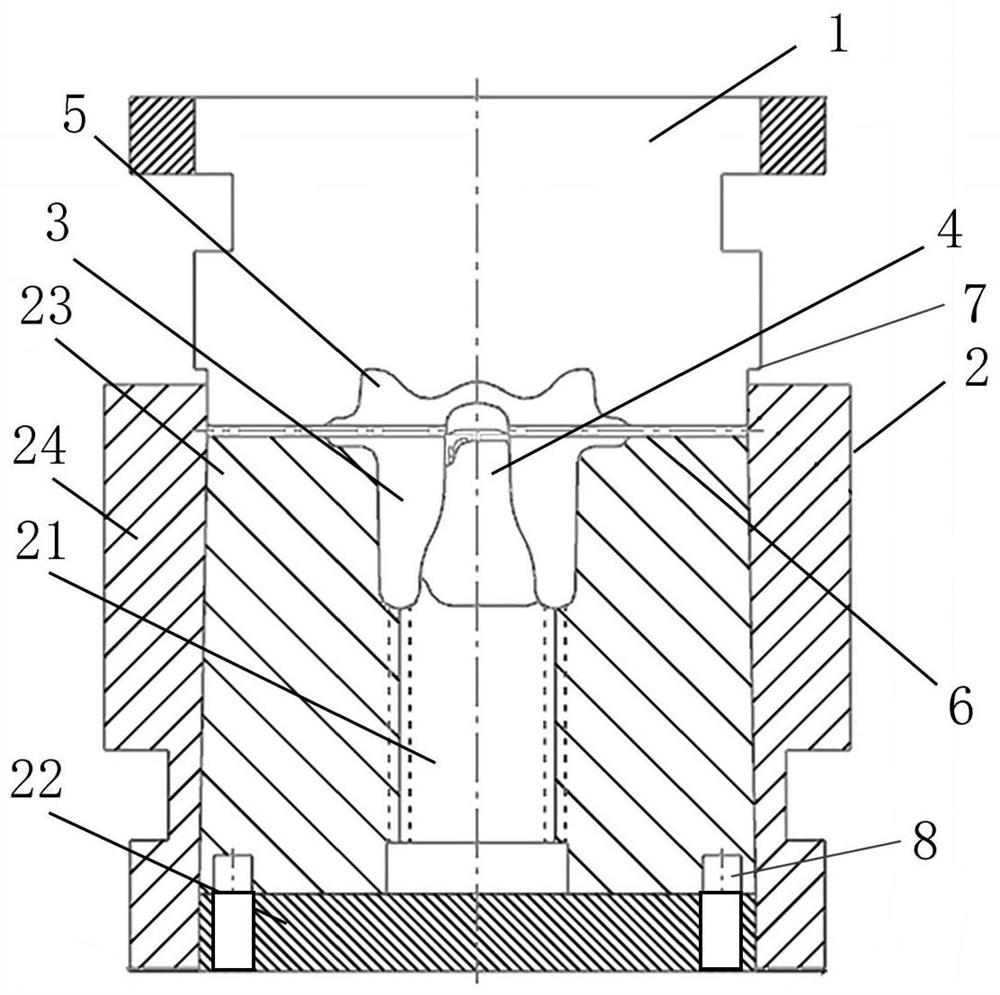

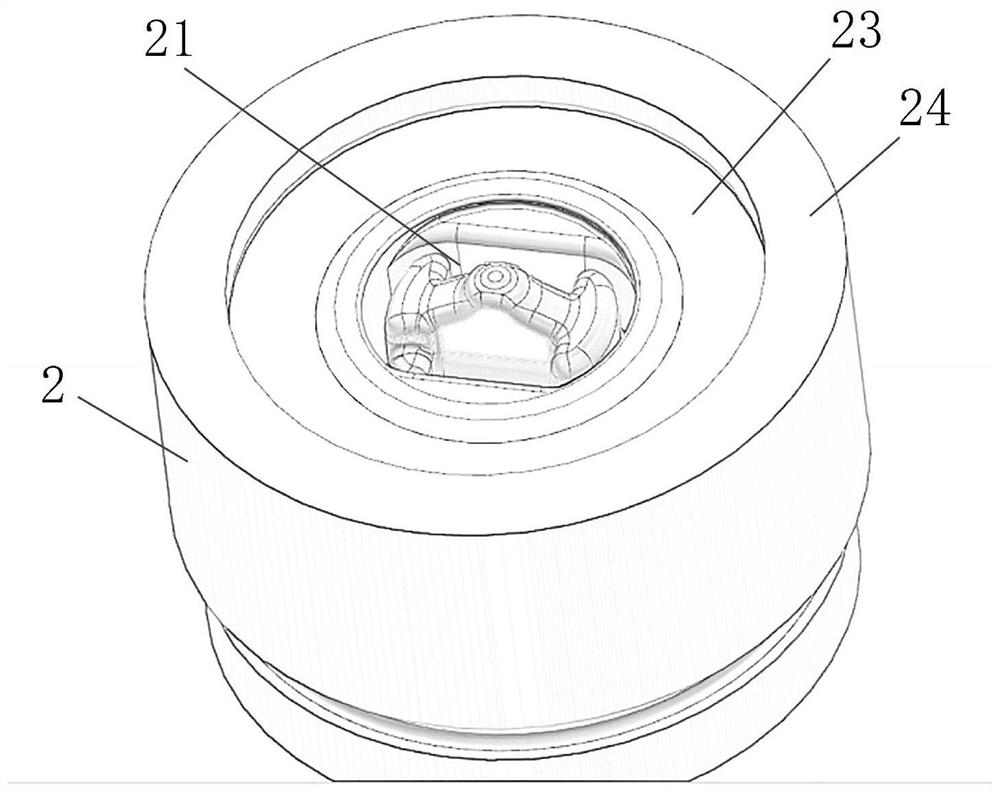

[0038] Embodiment 1, a kind of embedded hot forging piston die, as Figure 1-3 As shown, it includes two parts, upper mold 1 and lower mold 2.

[0039] The lower mold 2 includes four parts: core 21, inner ring 23, outer ring 24 and base 22. The four parts are embedded together. The inner ring 23 and base 22 are nested in the outer ring 24 from top to bottom, and the core 21 is nested Inside the inner ring 23 , the base 22 is located directly below the inner ring 23 and the core 21 . This split method can select different materials according to the stress of different parts, which can effectively reduce the stress of the part of the mold that is prone to cracking, and is also convenient for mold production; the contact surfaces between the core 21, the inner ring 23, the outer ring 24 and the base 22 Interference fit, which can avoid drilling burrs at the split position; a certain length of straight section needs to be set on the joint surface, which can play the role of anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com