Automatic opening and closing clamp for aluminum product machining

A technology for automatic opening and closing of aluminum products, applied in the field of aluminum product processing, which can solve the problems of increasing manufacturing costs, waste, and increasing the cost of fixture production, and achieve the effect of reducing costs and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

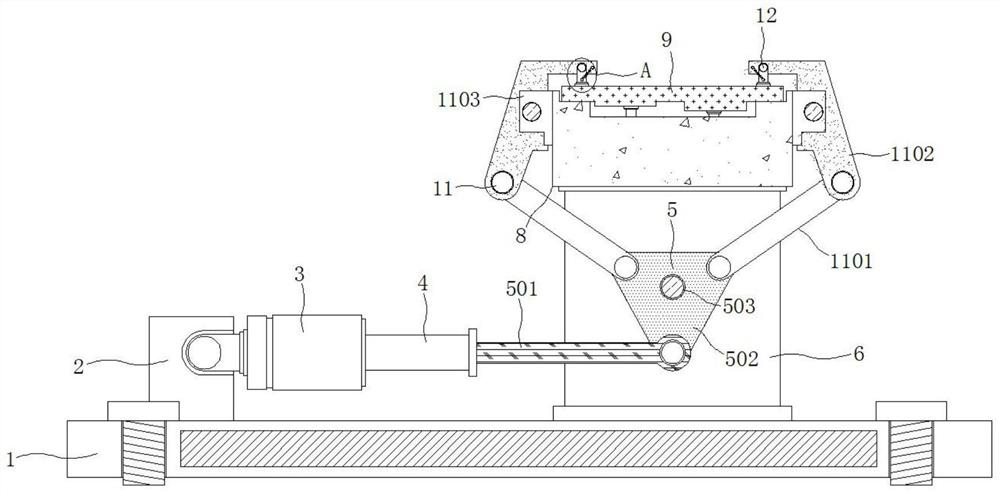

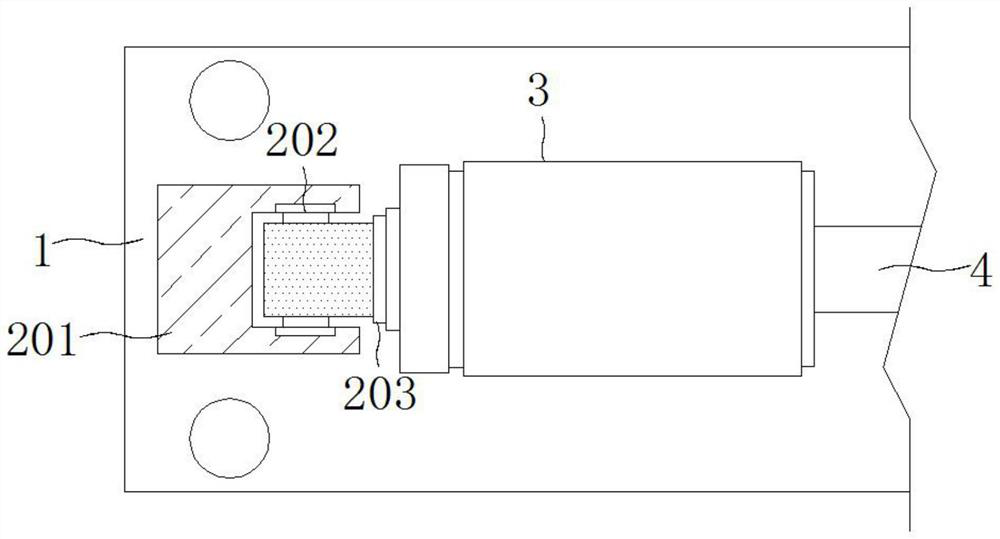

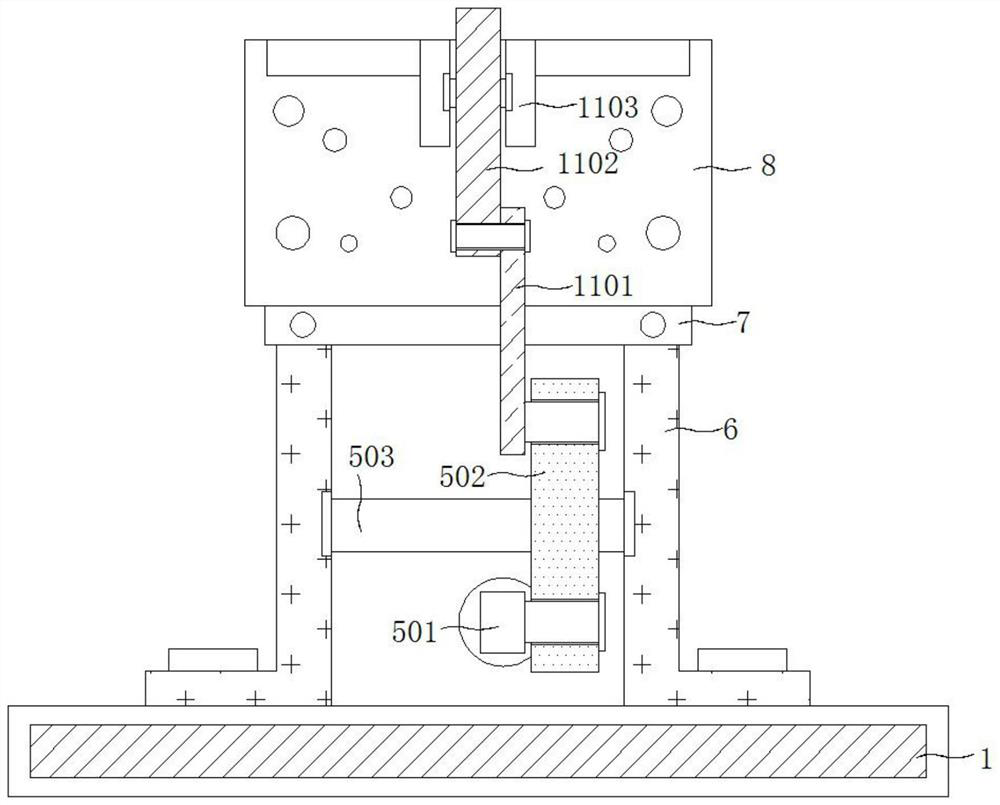

[0035] The specific implementation method is: when clamping and fixing the special-shaped aluminum product body 9, first place the special-shaped aluminum product body 9 on the top of the reference block 8, at this time, the bottom side of the special-shaped aluminum product body 9 and the top of the pressure-bearing mechanism 102 Contact and squeeze the internal parts of the pressure-bearing mechanism 102, through the contact between the special-shaped aluminum product body 9 of different thickness and the internal parts of the pressure-bearing mechanism 102, the movement range of the internal parts of each group of pressure-bearing mechanisms 102 is inconsistent, and each group The inconsistent movement of the internal parts of the pressure-bearing mechanism 102 can be balanced under the action of the internal parts of the balance mechanism 103, so that the top surface of the special-shaped aluminum product body 9 remains parallel to the horizontal plane, which is convenient f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com