Injection molding machine with material conveying function

A material transmission and injection molding machine technology, which is applied in the filtration of dispersed particles, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of difficult to ensure product quality, difficult to control the number and position of air bubbles, product hollowing, etc., to ensure product quality. Quality, reduce the time required, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

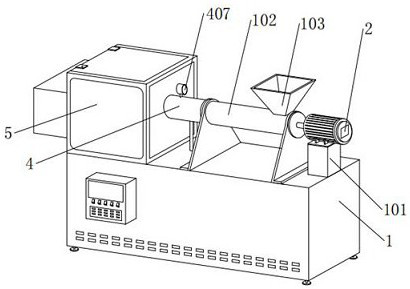

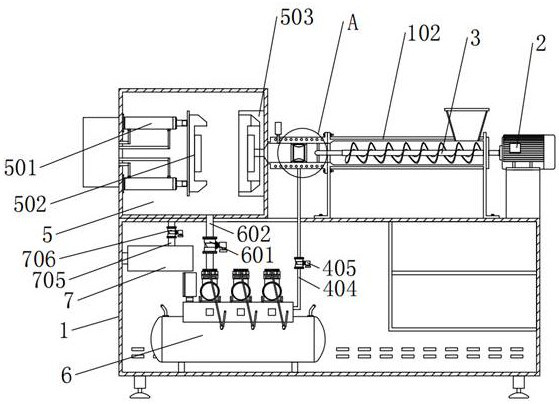

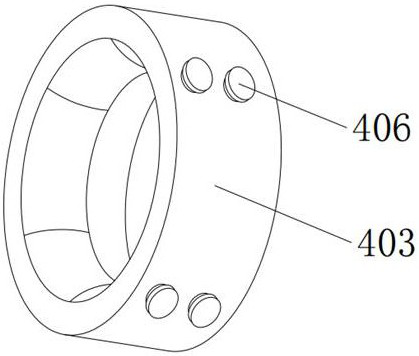

[0045] An injection molding machine with a material transmission function, comprising a box body 1, the upper end of the box body 1 is a working table, the front is an operating position, the top right side of the box body 1 is fixed with a motor bracket 101, and the top of the motor bracket 101 is equipped with a servo The motor 2, the casing 102 is fixedly installed in the middle position of the top of the box body 1, the top right side of the casing 102 is fixedly connected with the feed hopper 103, the inside of the casing 102 is embedded with an auger 3, and the left side of the casing 102 A heating bush 4 is fixedly connected through a flange, and a dustproof box 5 is fixed on the left side of the top of the box body 1;

[0046] Two pairs of hydraulic cylinders 501 are fixedly installed on the inner left side wall of the dustproof box 5, and a movable mold 502 is installed on one side of the hydraulic cylinder 501, and a fixed mold 503 is fixedly installed on the inner ri...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is: one end of the auger 3 is fixedly connected to the output end of the servo motor 2, the auger 3 and the bushing 102 are rotationally connected through a sealed bearing, and the end of the auger 3 is far away from the servo motor 2 provided with a circular opening;

[0052]One end of the heating rod 401 is embedded in the inside of the auger 3, and the heating rod 401 is closely attached to the auger 3;

[0053] The casing 102 communicates with the heating bush 4;

[0054] The auger 3 is sleeved on the outside of the heating rod 401. The auger 3 can fully exchange heat with the heating rod 401. The heating rod 401 conducts heat to the auger 3, and the raw material is heated by the auger 3 and its outer spiral blades. Preheating to increase the temperature of the raw material, and make the raw material heated evenly through the extrusion force of the auger 3 on the raw material;

[0055] The auger 3 transports ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com