3D printing manufacturing method of vibration isolation shoe midsole based on absolute zero-stiffness structure

A technology of 3D printing and manufacturing method, which is applied in the field of midsoles of vibration-isolated shoes, can solve the problems of lower bearing capacity of the sole, lack of theoretical guidance, weak bearing capacity, etc., and achieve simplified structure, changeable application occasions, and strong material compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] A 3D printing manufacturing method for the midsole of a vibration-isolation shoe based on an absolute zero stiffness structure, comprising the following steps:

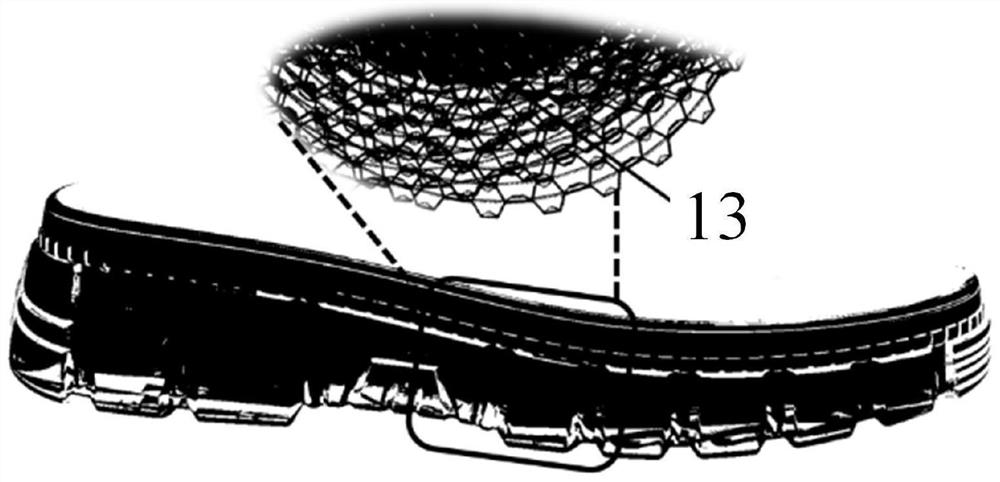

[0038] 1) Determine the load-bearing level of the midsole of the shoe according to the weight range of the user; in order to reduce the overall weight of the shoe, the midsole of the shoe adopts a hollowed-out lattice structure, and the arrangement of the lattice units is planned according to its overall size to ensure that the size of the lattice units does not vary. more than 1cm;

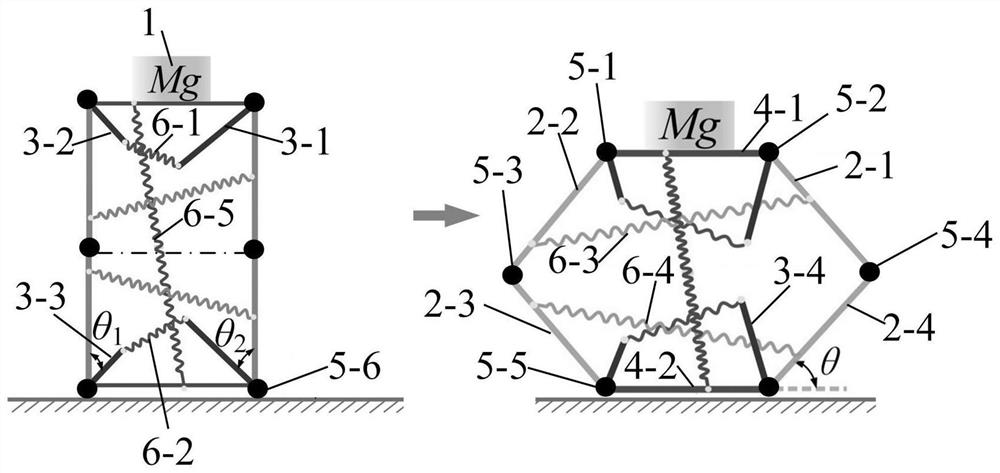

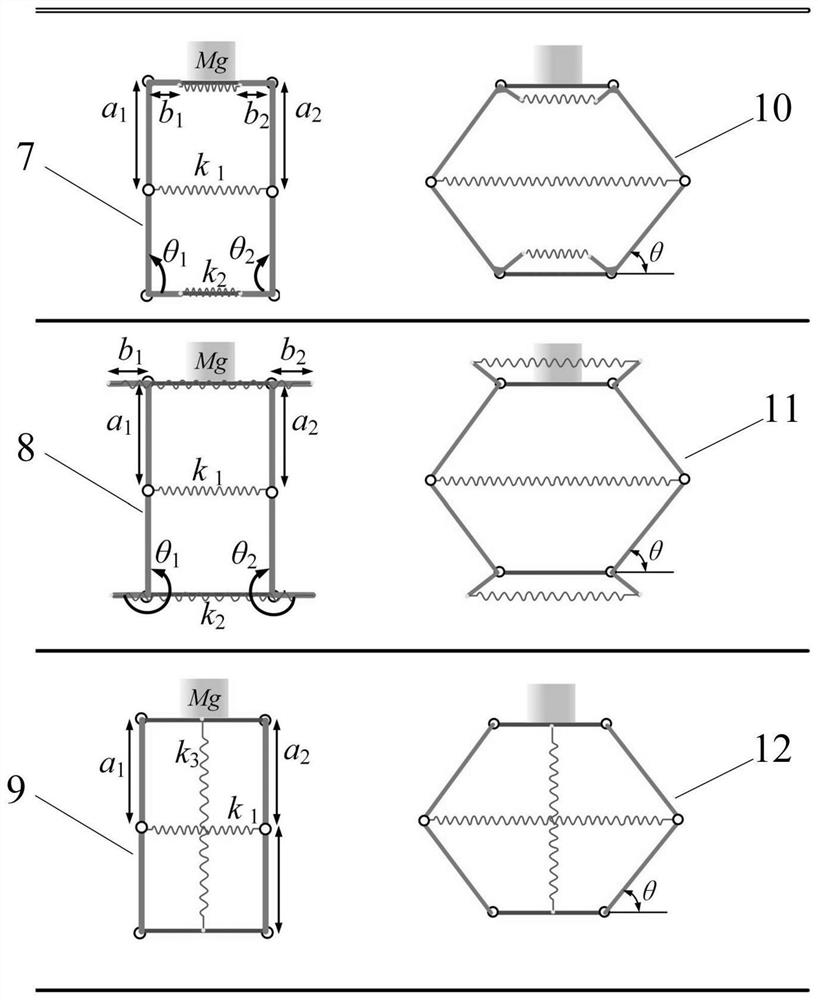

[0039] 2) Set an initial configuration for the lattice unit, such as figure 1As shown, the lattice unit includes an upper rigid arm 4-1, and the two ends of the upper rigid arm 4-1 are respectively connected to the first main rigid arm 2-1 and one end of the second main rigid arm 2-2 through the first fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com