Electrical equipment vibration isolation anti-impact device

An electrical equipment and vibration isolation technology, applied in non-rotational vibration suppression and other directions, can solve the problems of poor economy, lack of adaptability research and design, unable to meet the design requirements of marine electrical equipment, etc., and achieve the effect of high-efficiency vibration isolation and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

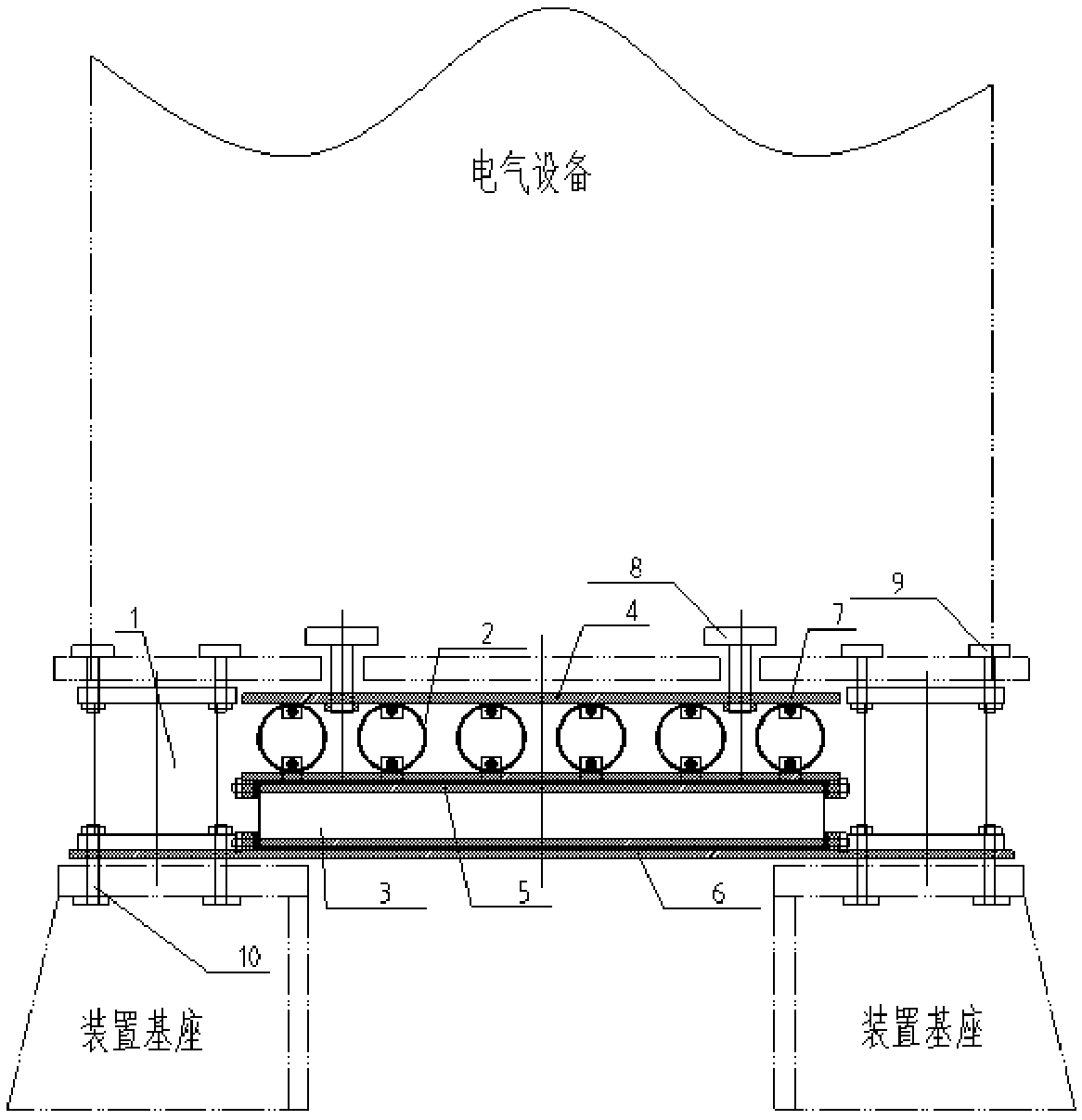

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

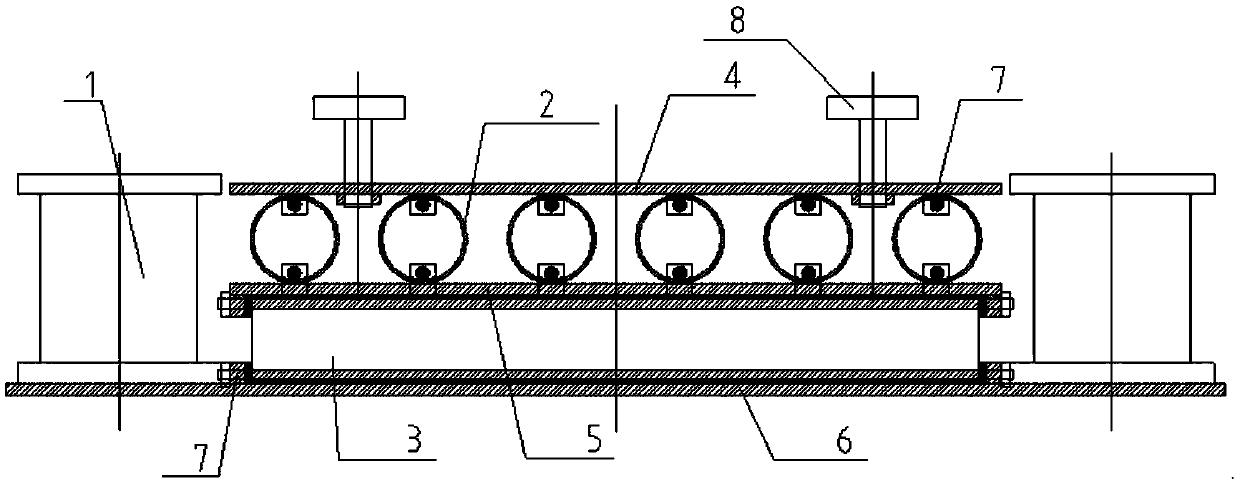

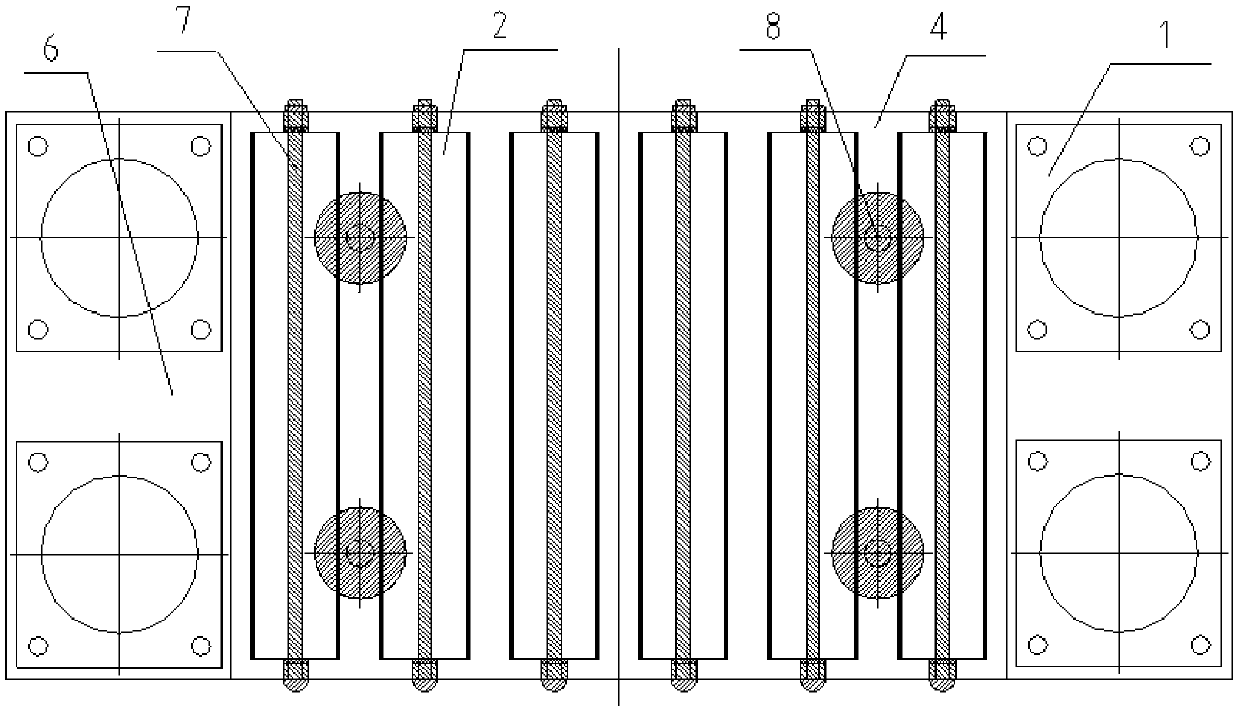

[0021] as attached figure 1 and 2 As shown, the present invention provides a vibration isolation and anti-shock device for electrical equipment,

[0022] GF1100A type composite damping vibration isolator 1 is connected to the lower mounting panel 6 (made of titanium alloy TC4 plate, thickness 16mm, size 1000mm*500mm) through bolts and nuts; the lower cylindrical shell 3 (made of TiNi alloy, wall thickness 1.0mm, diameter 80mm) , length 650mm) through the fixed connecting rod 7 (composed of vulcanized rubber vulcanized 1mm outside the stainless steel rod with a diameter of 10mm) and the lower installation panel 6 and the middle partition 5 (using titanium alloy TC4 plate, thickness 16mm, size 690mm*500mm ) is fixed; the upper cylindrical shell 2 (made of TiNi alloy, wall thickness 1.0mm, diameter 80mm, length 465mm) is connected with the upper mounting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com