Automatic pressing device for insulation board production

A technology of pressing device and thermal insulation board, applied in the field of thermal insulation board, can solve problems such as displacement of thermal insulation board, replacement of positioning device, thermal insulation board does not meet process requirements, etc., to achieve the effect of increasing the scope of application and preventing glue from solidifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

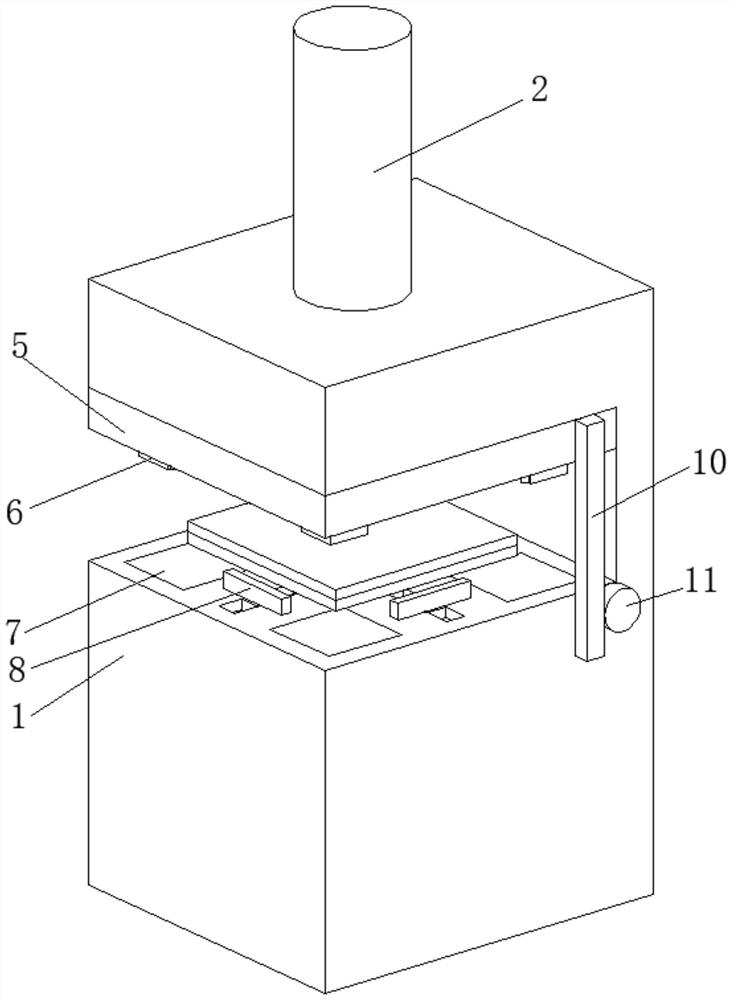

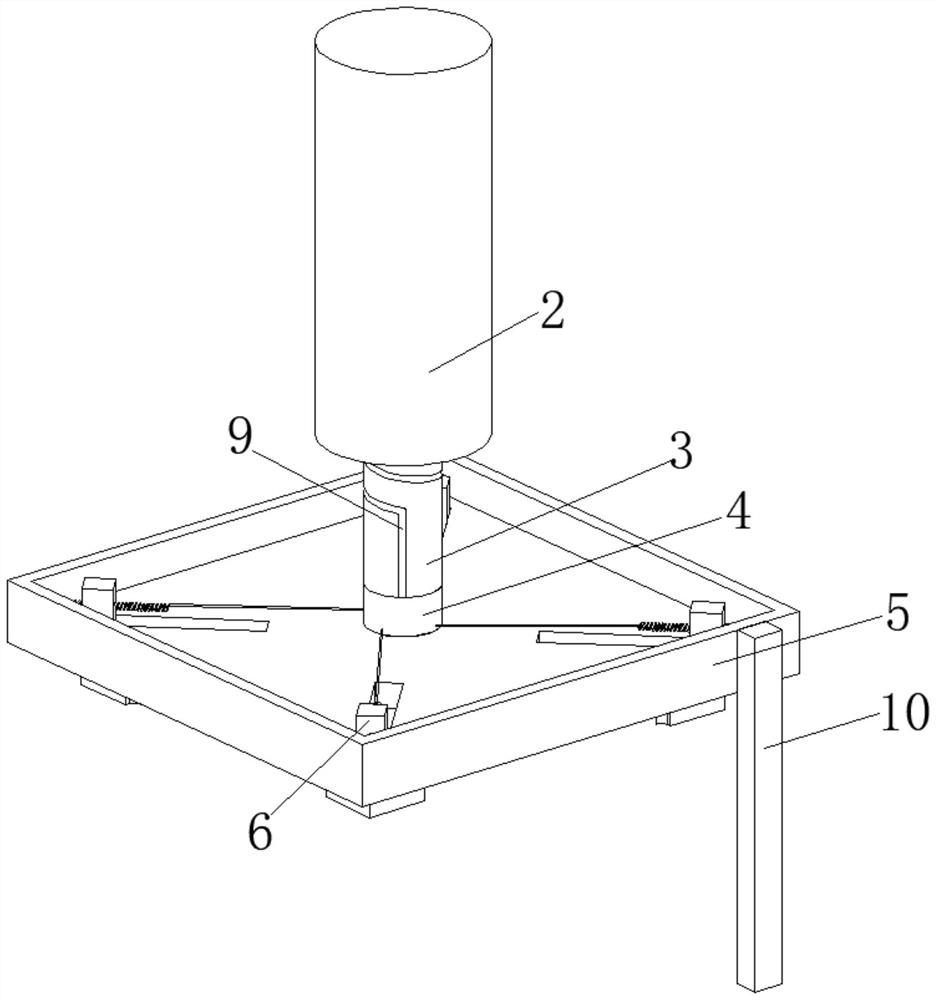

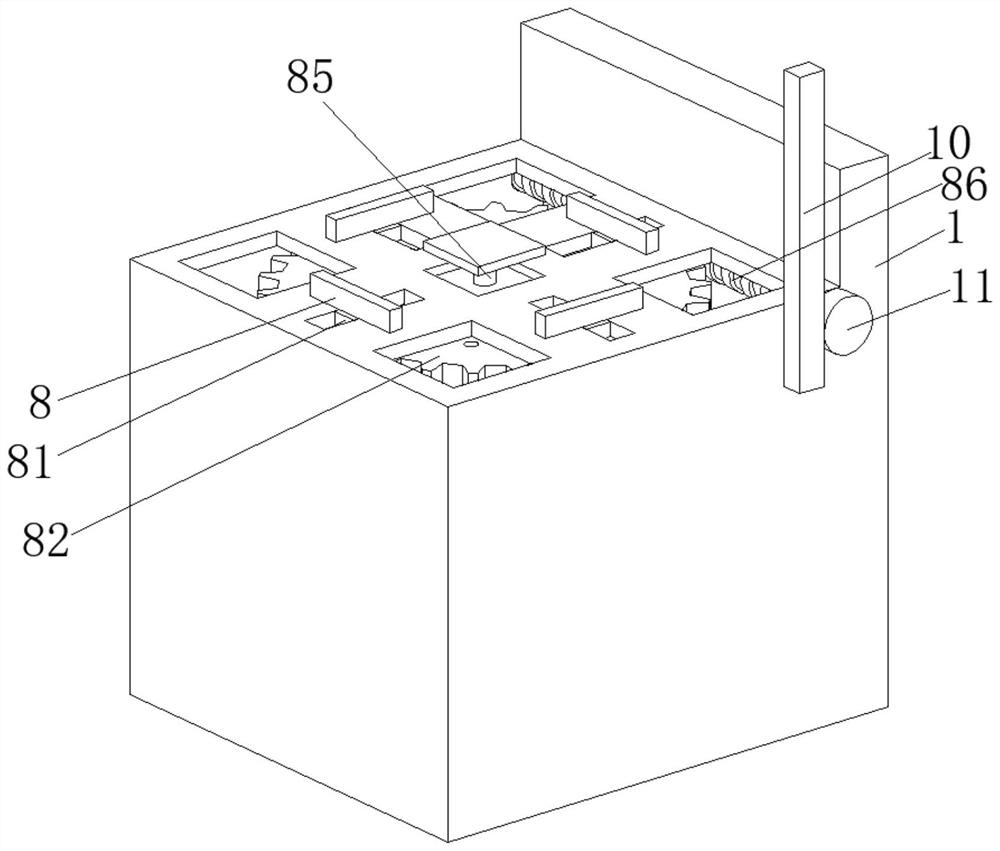

[0028] An automatic pressing device for the production of insulation boards, such as Figure 1-Figure 8 As shown, it includes the body 1, the top of the body 1 is fixedly connected with the oil cylinder 2, the output end of the oil cylinder 2 is fixedly connected with the pressure rod 3, the inner wall of the pressure rod 3 is slidably connected with the inner rod 4 through the spline and the spring, and the inner rod 4 The bottom end is fixedly connected with a pressure plate 5, and the front part of the pressure plate 5 is fixedly connected with a friction plate 10. The surface of the friction plate 10 and the surface of the friction disc 11 are in contact with each other. The inner wall of the body 1 is connected with a worm wheel 82 in rotation. A chute 83, the inner wall of the chute 83 is movably connected with a slider 81 through a connecting rod, the top of the slider 81 is fixedly connected with a splint 8, the inner wall of the worm wheel 82 is slidably connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com