Multifunctional sewage treatment equipment

A kind of sewage treatment equipment and multi-functional technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical/physical process, etc. filtration efficiency and other issues, to avoid the generation of sediment, reduce labor intensity, and reduce time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A multifunctional sewage treatment equipment, such as Figure 1-Figure 2 As shown, it includes a bottom plate 1, a first slide bar 2, a pressing plate 3, a first spring 4, a filter plate 5, a stirring mechanism 6 and a discharge mechanism 7, and the top left and right sides of the bottom plate 1 are rotatably provided with a first slide bar. 2. The number of the first sliding rods 2 is two, and the first springs 4 are set on the two first sliding rods 2. The inner ends of the slide bars 2 are fixedly connected with a pressure plate 3, the number of the pressure plate 3 is two, and a filter plate 5 is connected between the two pressure plates 3, the number of the filter plate 5 is two, and the bottom plate 1 is equipped with a stirring mechanism 6 , The upper part of the stirring mechanism 6 is provided with a discharge mechanism 7, and the filter plate 5 is located above the discharge mechanism 7.

[0026] When a worker needs to process sewage, the worker first pours t...

Embodiment 2

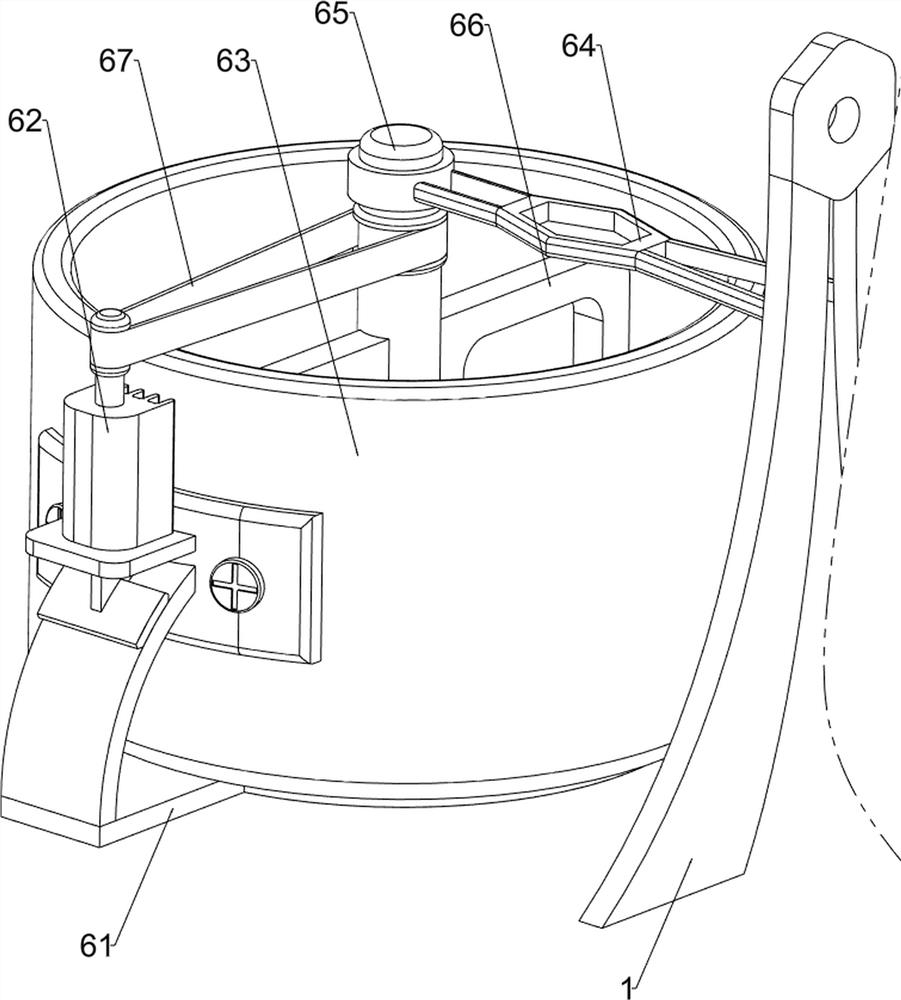

[0028] In a preferred embodiment of the present invention, as Figure 3-Figure 8 As shown, the stirring mechanism 6 includes a first support frame 61, a motor 62, a first water tank 63, a second support frame 64, a rotating rod 65, a stirring rod 66 and a belt 67, and the front portion above the bottom plate 1 is provided with a first support frame 61, the motor 62 is installed on the first support frame 61, the first support frame 61 is provided on the lower part of the bottom plate 1, the first water tank 63 is placed on the first support frame 61, and the motor is fixed on the upper part of the front side of the first support frame 61 through bolts 62, a second support frame 64 is connected between the inner lower part of the base plate 1, the second support frame 64 is located above the first water tank 63, the middle part of the second support frame 64 is rotatably provided with a rotating rod 65, and the lower part of the rotating rod 65 is provided with a stirring rod 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com