Construction method for integrally and synchronously arranging multiple layers of large-tonnage inner supports in cofferdam

A construction method and large-tonnage technology, applied in infrastructure engineering, construction, etc., can solve problems such as long time consumption, and achieve the effects of shortening construction time, setting reasonable construction steps, and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following is attached Figure 1-8 The application is described in further detail.

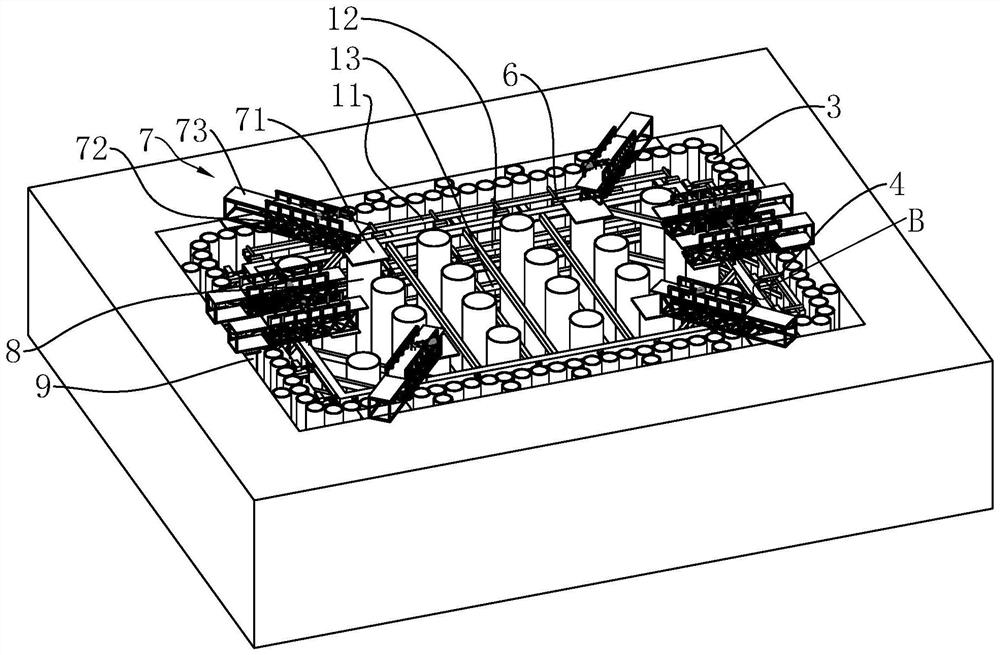

[0049] The embodiment of the present application discloses a construction method for the overall synchronous deployment of multi-layer and large-tonnage inner supports in the cofferdam, which is used for the arrangement of the inner support system inside the cofferdam of steel pipe piles 3 .

[0050] refer to figure 1 , the internal support system includes three layers of internal support structures arranged in sequence from top to bottom, and the order from top to bottom is the first internal support structure 11 , the second internal support structure 12 and the third internal support structure 13 .

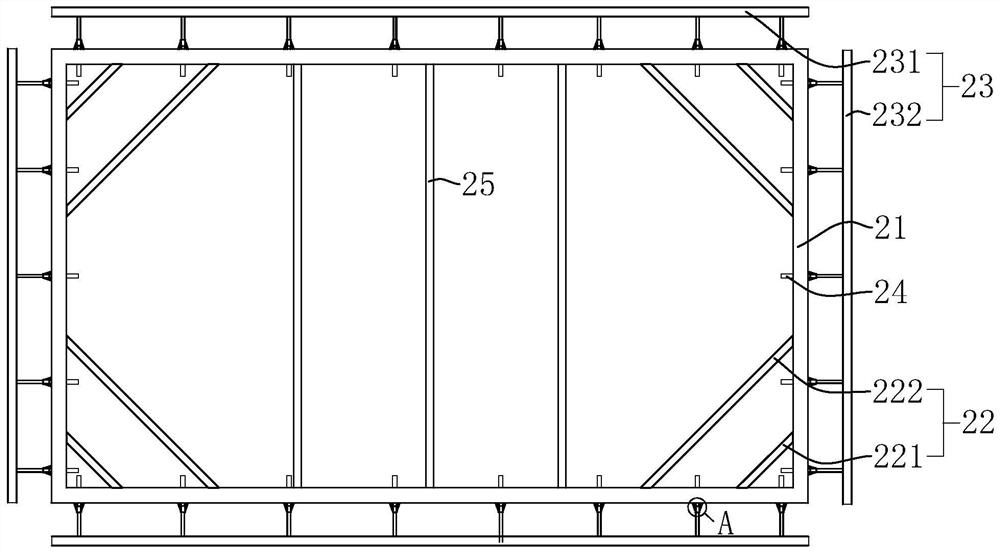

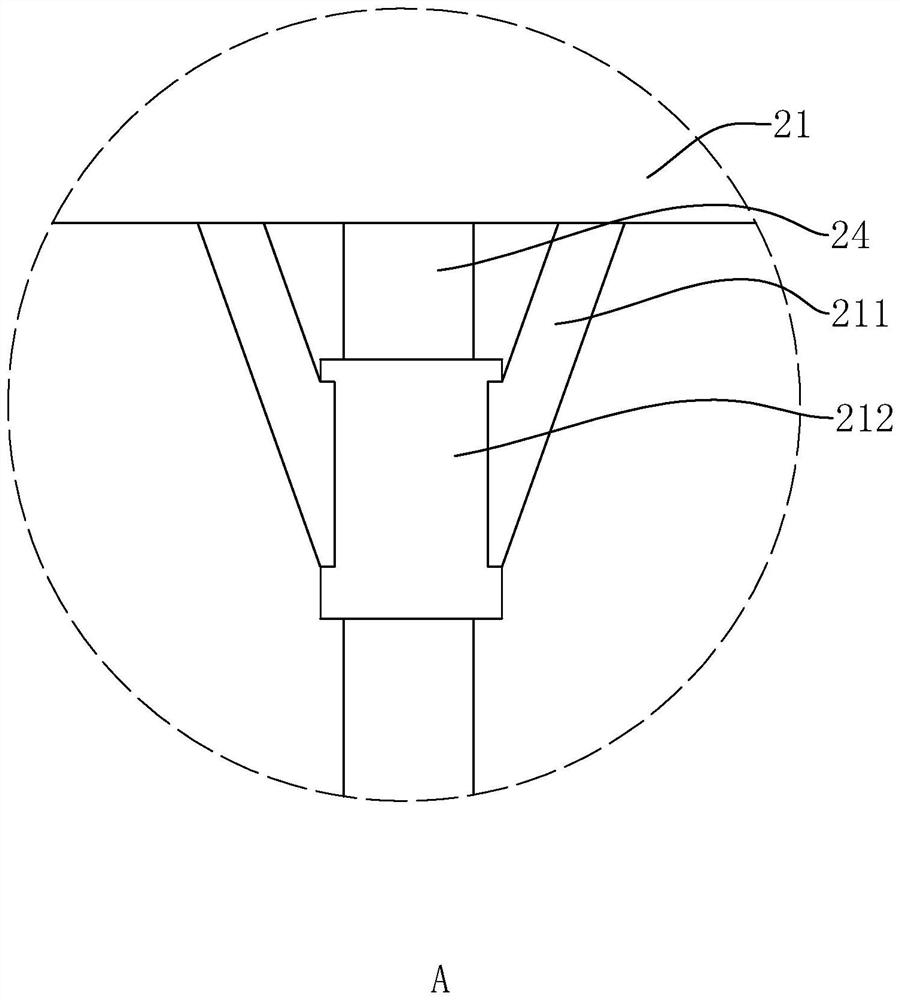

[0051] combine figure 1 with figure 2 , the inner support structure includes a rectangular inner purlin 21, a diagonal brace 22 fixed on the inner side of the inner purlin 21, a cross brace 25 fixed on the inner side of the inner purlin 21, and a movable beam 23 arranged around th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com