Steel structure stiff frame column and over-limit beam connecting structure and construction method thereof

A technology for connecting structures and frame columns, applied in structural elements, building components, building structures, etc., can solve problems such as inability to guarantee construction quality, forming effect, and inability to ensure effective connection, and achieve small errors, convenient construction, and high bearing capacity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

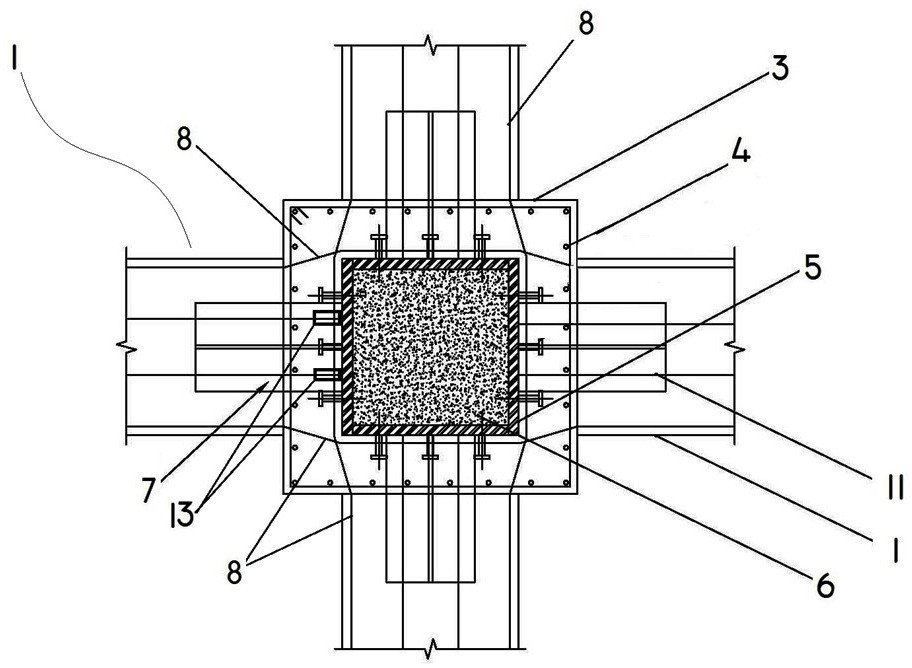

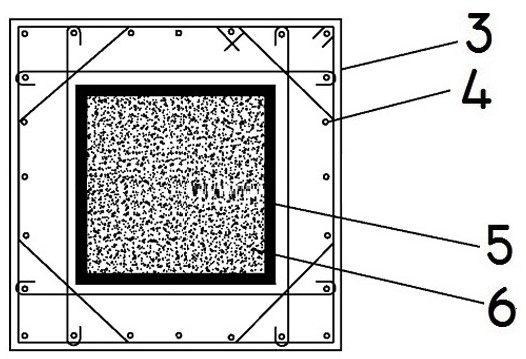

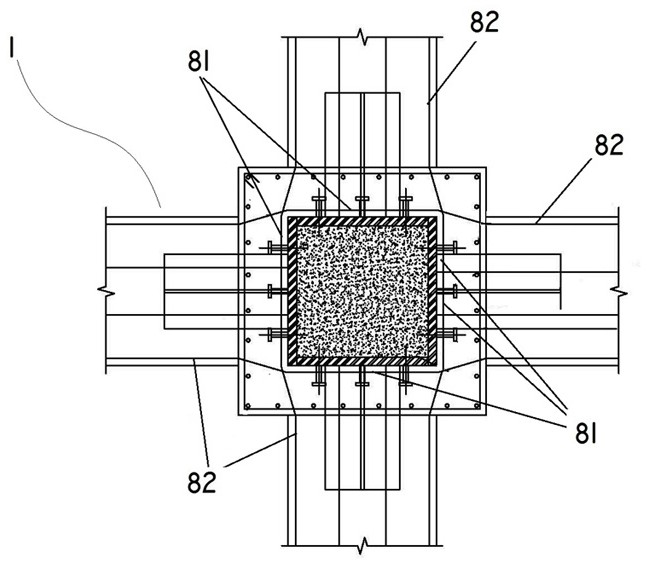

[0048] see Figure 1-Figure 6As shown, the present invention provides a connection structure between a steel structure stiff frame column and an overrunning beam, comprising a steel structure stiff frame column with a cross section of 1000*1000 mm, and overrun beams arranged on four sides of the steel structure stiff frame column 1 and fill the concrete layer arranged at the connection node between the steel structure stiff frame column and the overrun beam 1, the steel structure stiff frame column includes a rectangular frame column body 3, a column body fitting arranged on the inner surface of the frame column body 3 Rib 4 , square steel column core member 5 arranged in the center of frame column body 3 , C40 high-strength non-shrinkage CGM grouting filler 6 and limit fastening rib 8 filled in square steel column core member 5 . The limiting fastening rib 8 is Ω-shaped, including an intermediate limiting portion 81 and a fixed portion 82 symmetrically arranged at both ends o...

Embodiment 2

[0066] Embodiment 2, a connection structure of stiff frame columns and overrunning beams of a steel structure and its construction method are the same as in Embodiment 1, except that the upper longitudinal reinforcement 11 includes a first longitudinal reinforcement 101 and a second longitudinal reinforcement 102; see Figure 7 and 8 shown.

[0067] The short side of the horizontal connecting plate 7 is fixedly connected to the outer surface of the frame column body 3, the upper end surface of the horizontal connecting plate 7 is fixedly connected to the lower end surface of the first longitudinal rib 101, and the first longitudinal rib 101 is close to the outer surface of the frame column body 3. There is a gap between one side and the outer surface of the frame column body 3, and there is no sleeve outside the end of the first longitudinal rib 101; there are two second longitudinal ribs 102 and are symmetrically arranged on the outer side of the long side of the horizontal ...

Embodiment 3

[0068] Embodiment 3, a steel structure stiff frame column and overrunning beam connection structure and its construction method, is the same as Embodiment 1, and no sleeve is provided at the end of the upper longitudinal reinforcement 11 . It also includes a rectangular horizontal receiving plate 10 arranged directly below the horizontal connecting plate 7, one side of the short side of the horizontal receiving plate 10 is fixedly connected with the frame column body 3, and the upper end surface of the horizontal receiving plate 10 is fixedly connected with the lower end surface of the lower longitudinal rib 12; A vertical connecting plate 14 is also arranged between the receiving plate 10 and the horizontal connecting plate 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com