Laminated slab for fabricated building and construction method

A laminated slab and assembled technology, which is applied in the processing of building materials, construction, building components, etc., can solve the problems of laminated slabs not forming effective connections, support system instability, systemic instability, etc., to reduce plant facilities The effect of investment, improvement of bending resistance, and improvement of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

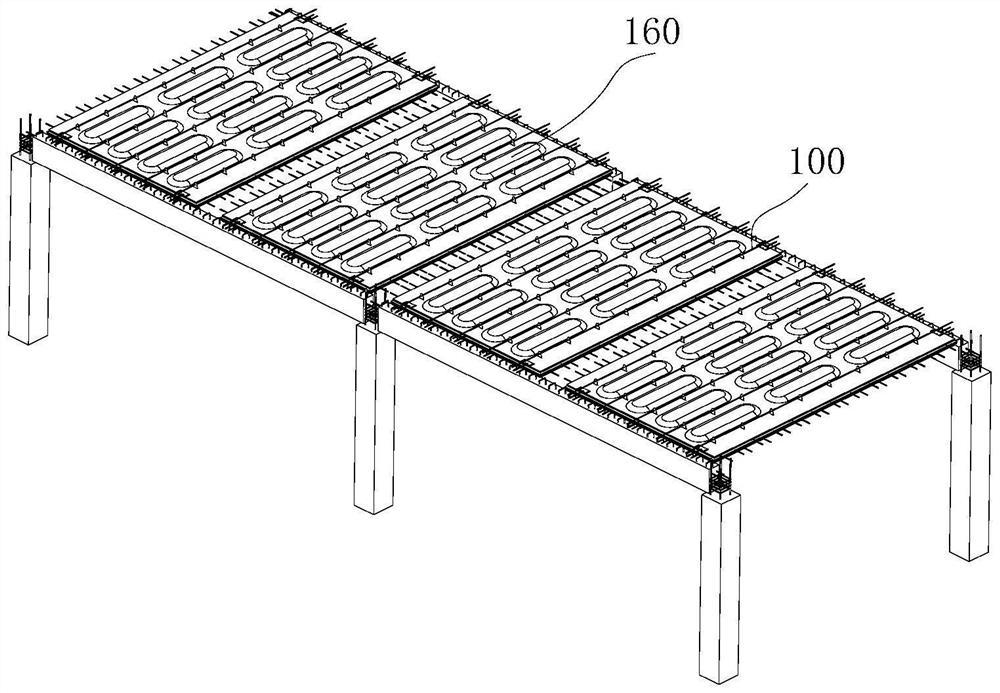

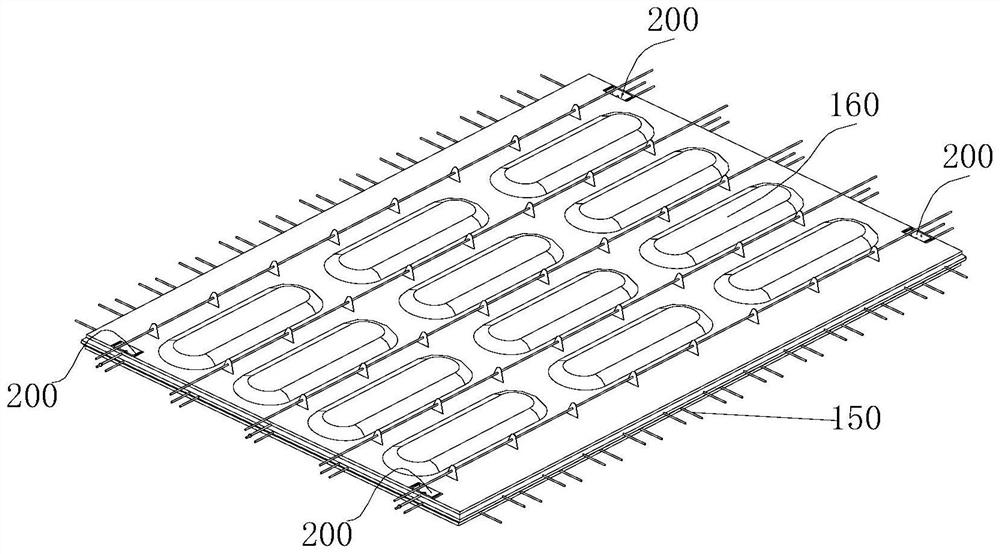

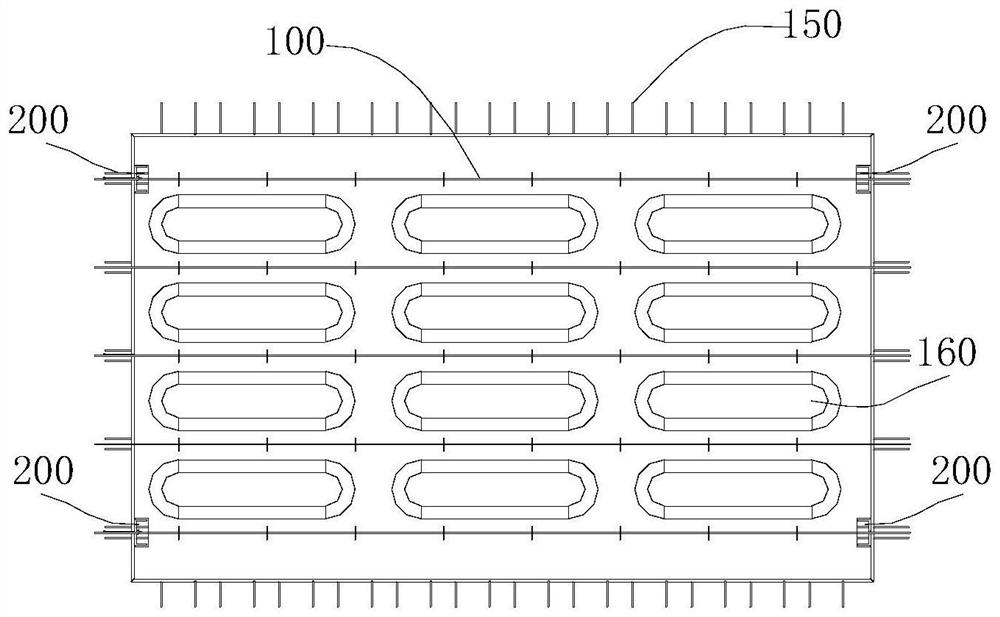

[0061] see Figure 1 to Figure 12 , an embodiment of the present invention provides a laminated slab for a prefabricated building, which includes a steel mesh and precast concrete partially poured on the steel mesh;

[0062] The reinforcement mesh includes several reinforcement frames 100 arranged side by side;

[0063] The steel bar frame 100 includes three straight bars 110 arranged in the shape of "品", a number of supporting pieces 120 that are respectively matched with the three straight bars 110 and evenly arranged along the centerline direction of the straight bars 110, and correspondingly located on the straight bars 110. Two connectors 140 at both ends;

[0064] The straight ribs 110 include a top straight rib 101 at the top of the "pin" shape, and two foot straight ribs 102 at the bottom of the "pin" shape;

[0065] The connectors 140 are matched with the two leg straight ribs 102 respectively;

[0066] The top of the support sheet 120 and the top straight bars 101...

Embodiment 2

[0089] On the basis of embodiment 1, the others are the same as embodiment 1, and the difference from embodiment 1 is: the top straight rib 101 is set as angle steel or channel steel, and the contour of the corresponding first perforation 121 in the supporting sheet 120 is corresponding to it. corresponding, see attached Figures 12 to 14 .

[0090] Or the top straight bar 101 is set as a steel pipe, round steel pipe or square steel pipe can be used, and high-strength concrete is poured in the steel pipe, so that the steel pipe forms a solid structure, which can further improve the bending strength of the laminated slab, especially can make the laminated slab It has strong bending resistance, and the contour of the corresponding first perforation 121 in the supporting sheet 120 corresponds to it, see the attached Figure 15 , 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com