Patents

Literature

36results about How to "Less investment in facilities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

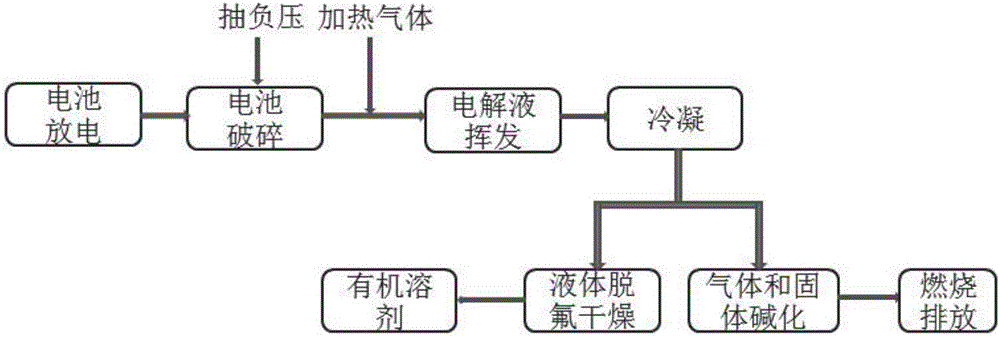

Recovery method for electrolyte of waste lithium ion battery

ActiveCN106684487ALow costPrevent leakageWaste accumulators reclaimingBattery recyclingRecovery methodOrganic solvent

The invention discloses a method for safe dismantling of a waste lithium ion battery and green recovery of an internal electrolyte. The method mainly comprises the steps of (1) performing short-circuit discharging on a waste battery; (2) performing dismantling and smashing on the battery in a negative pressure space; (3) blowing drying hot gas to battery fragments smashed in the negative pressure space to volatilize the electrolyte; and (4) performing condensing, filtering and alkali adding and fluorine removing on volatile components to obtain a relatively pure organic solvent, and performing innocent treatment on the residual gas and solid-state granules. According to the method, the battery is dismantled by the negative pressure environment, a contact area with the battery fragments can be enlarged by hot air flow, so that air flow with high stability is formed, the electrolyte solvent is recycled effectively and simply, and the advantage of low cost is realized; and meanwhile, the harmful substances in the electrolyte are subjected to the innocent treatment, so that environment friendliness and industrial recovery and utilization can be realized.

Owner:CENT SOUTH UNIV

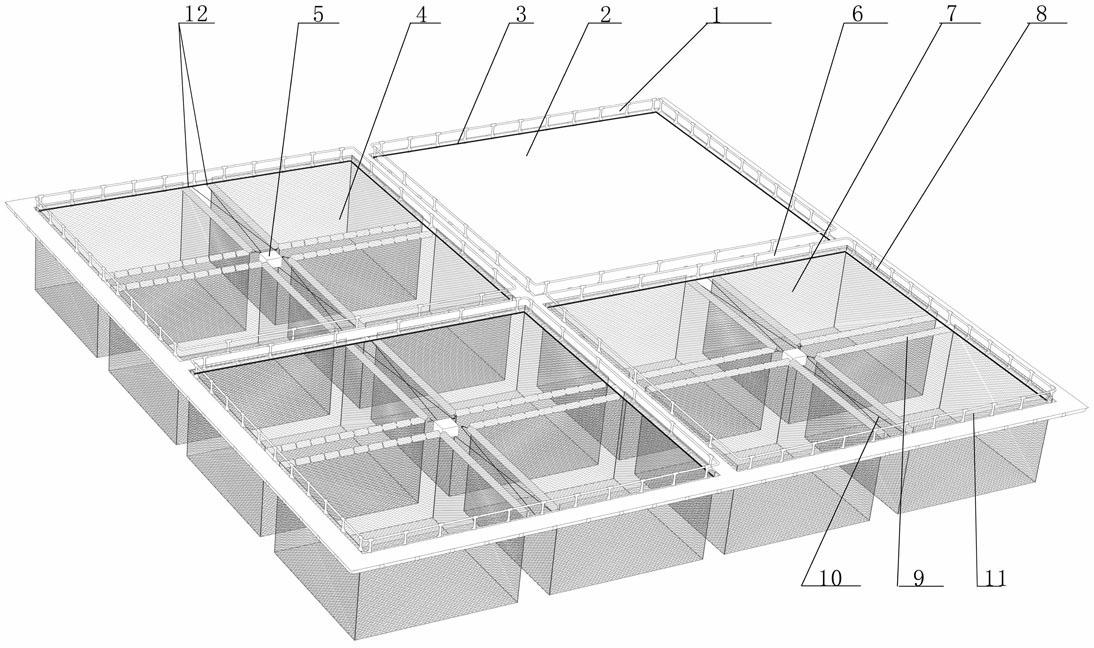

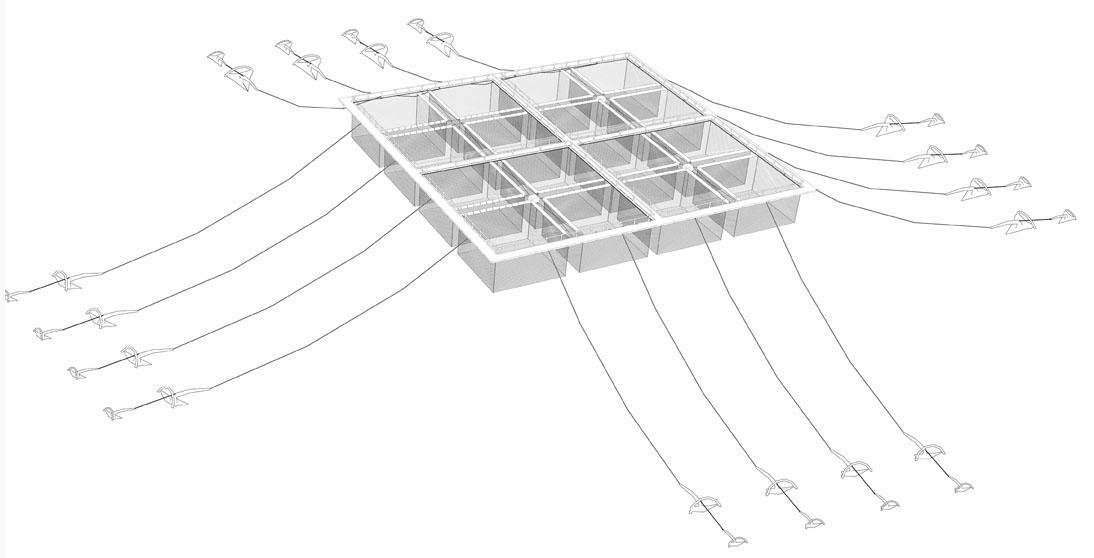

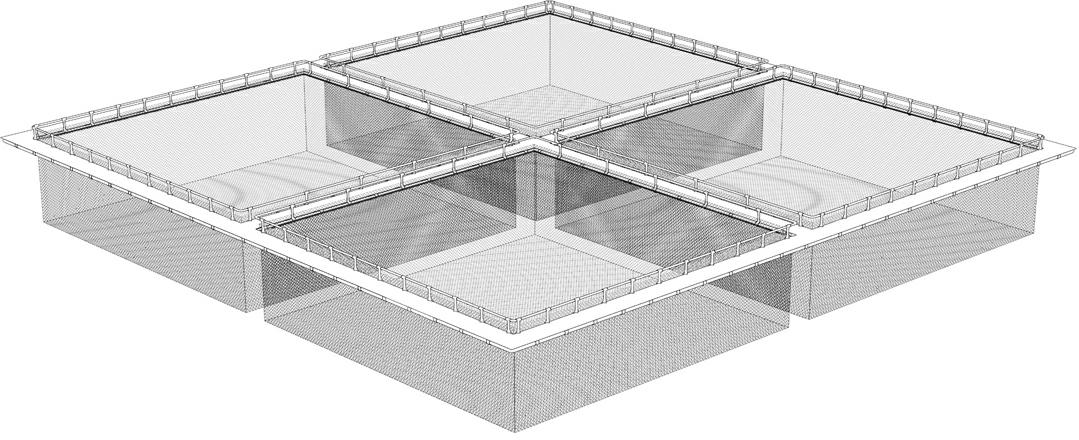

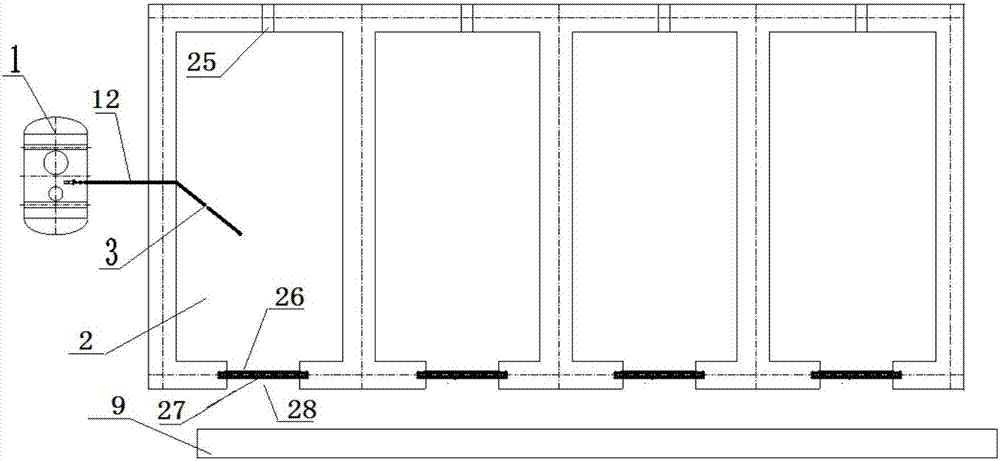

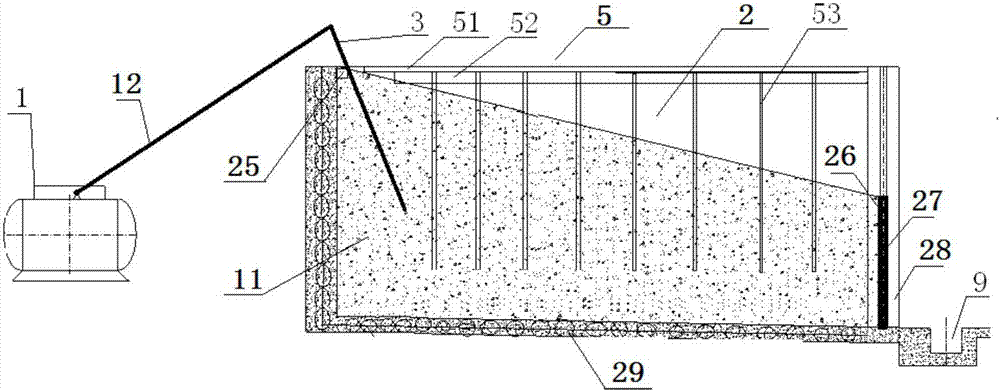

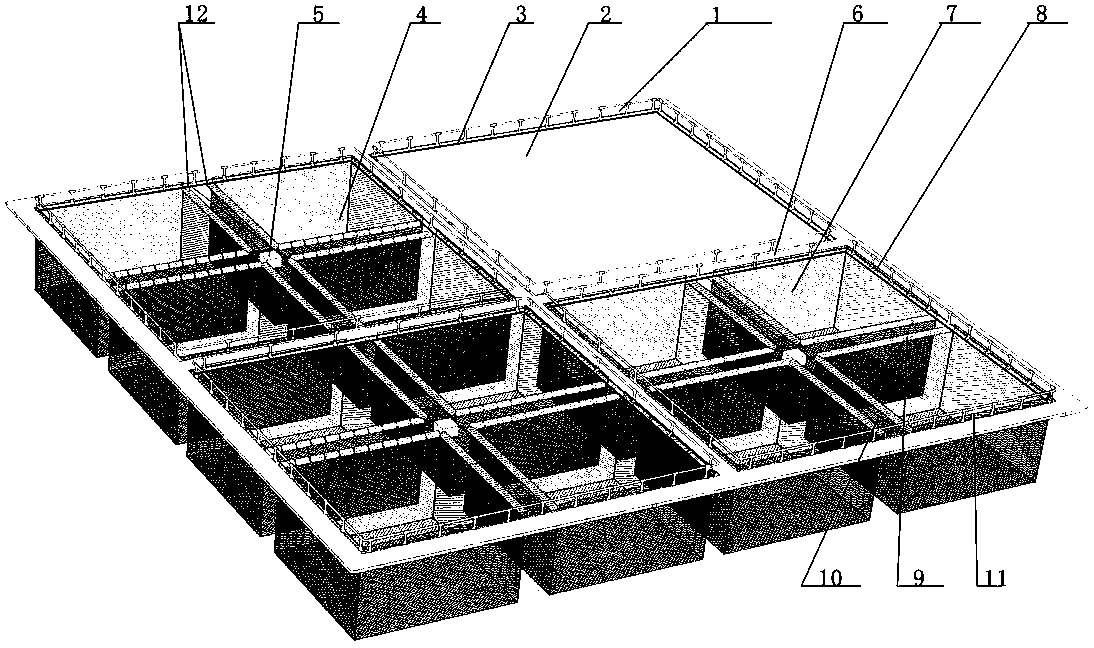

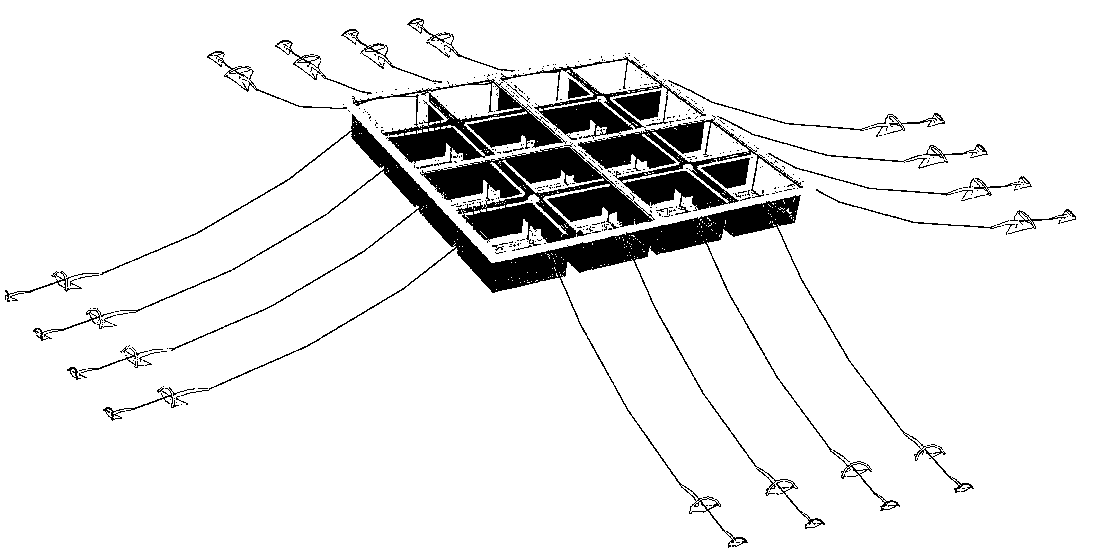

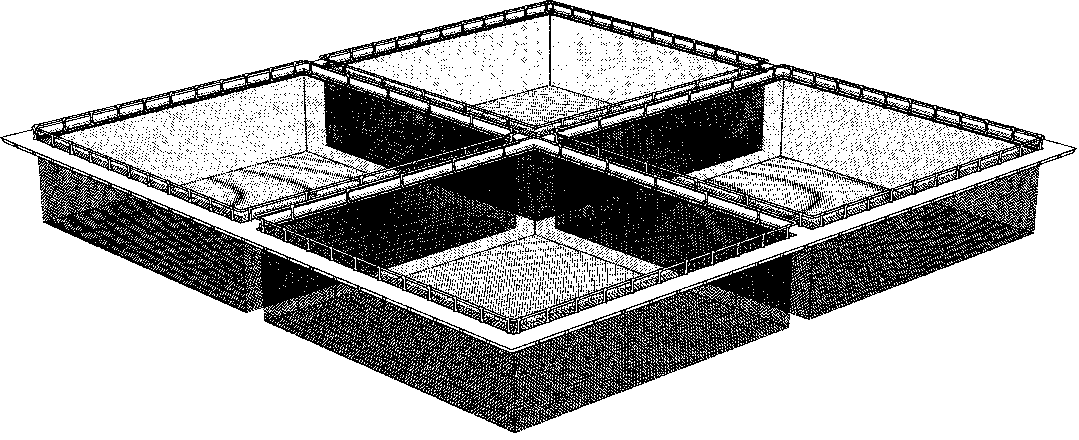

Combined wind wave and current resistant net cage and working method thereof

InactiveCN102630613AImprove typhoon resistanceRaise the level of modernizationClimate change adaptationPisciculture and aquariaHigh-density polyethyleneEngineering

The invention discloses a combined wind wave and current resistant net cage and a working method thereof. The combined wind wave and current resistant net cage comprises a high-density polyethylene (HDPE) integrated framework and net cage bodies, and is characterized in that a plurality of square net cage units are arranged in the integrated framework formed by an HDPE tube; floating rope frames formed by a high-intensity fiber rope are arranged at the peripheries of the square net cage units below each edge of the HDPE integrated framework; a plurality of net cage bodies are arranged in the floating rope frames; and every two adjacent net cage bodies in the same square net cage unit are fixed by a multi-net-cage connector. The combined wind wave and current resistant net cage has excellent wind wave and current resistance, can keep the shapes of the net cage bodies stable and is structurally similar to the conventional fish raft; on the premise that water inside and outside the net cage can be well exchanged, the flowing deformation performance of the net is improved thoroughly; and furthermore, cultivation is convenient to manage; and the facility investment is relatively low.

Owner:FISHERIES RES INST OF FUJIAN

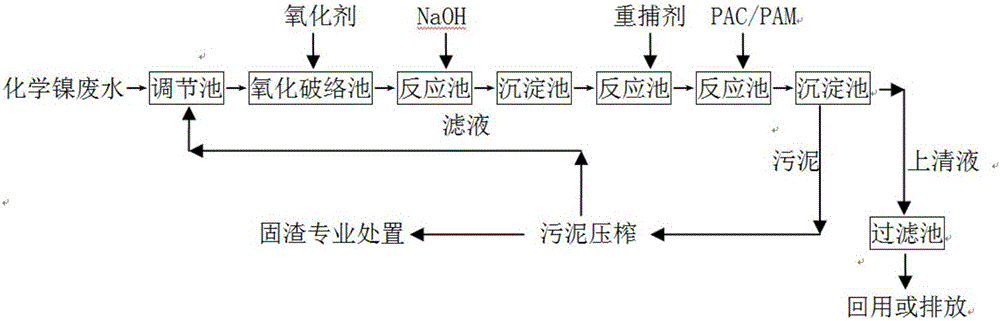

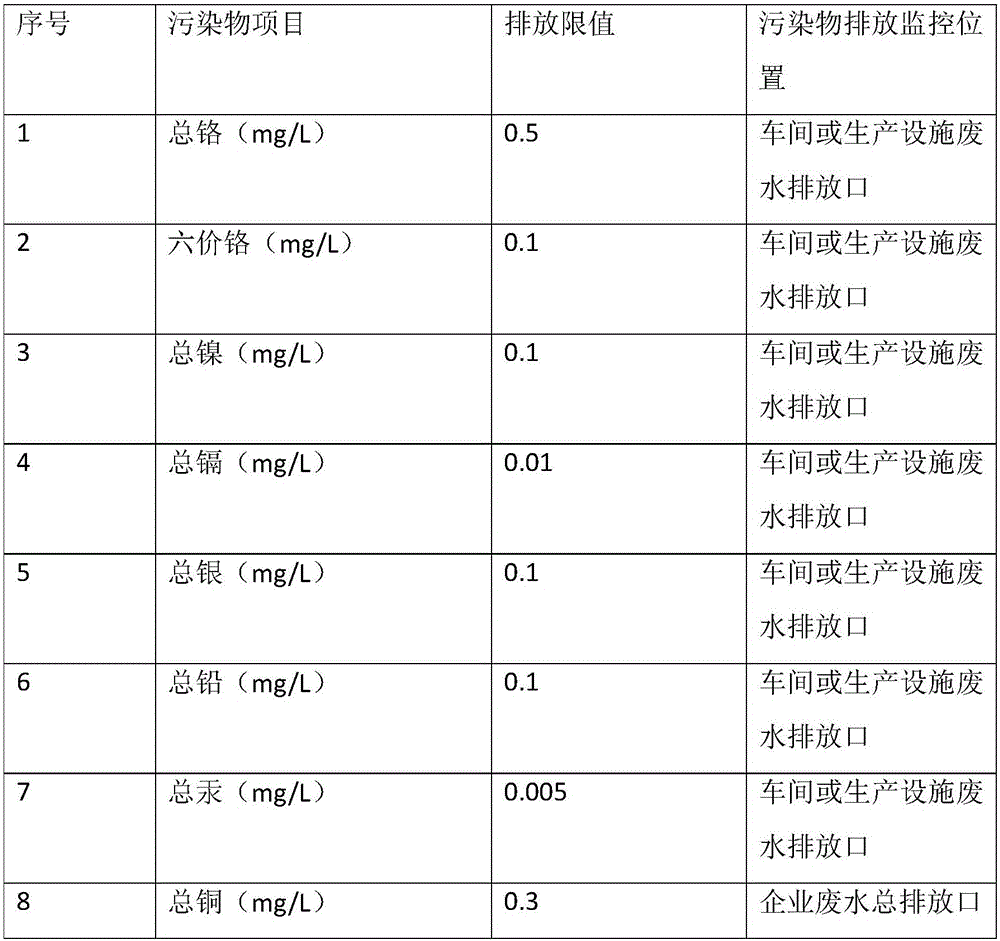

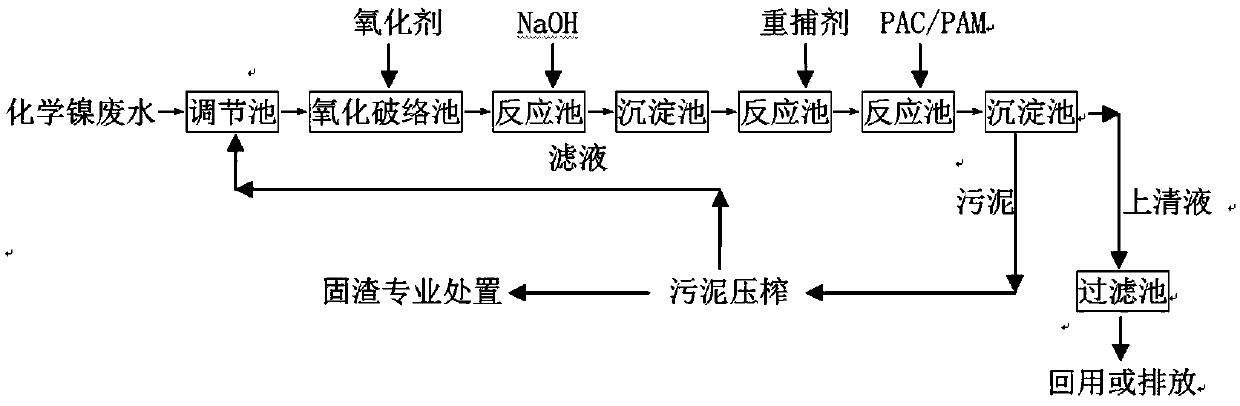

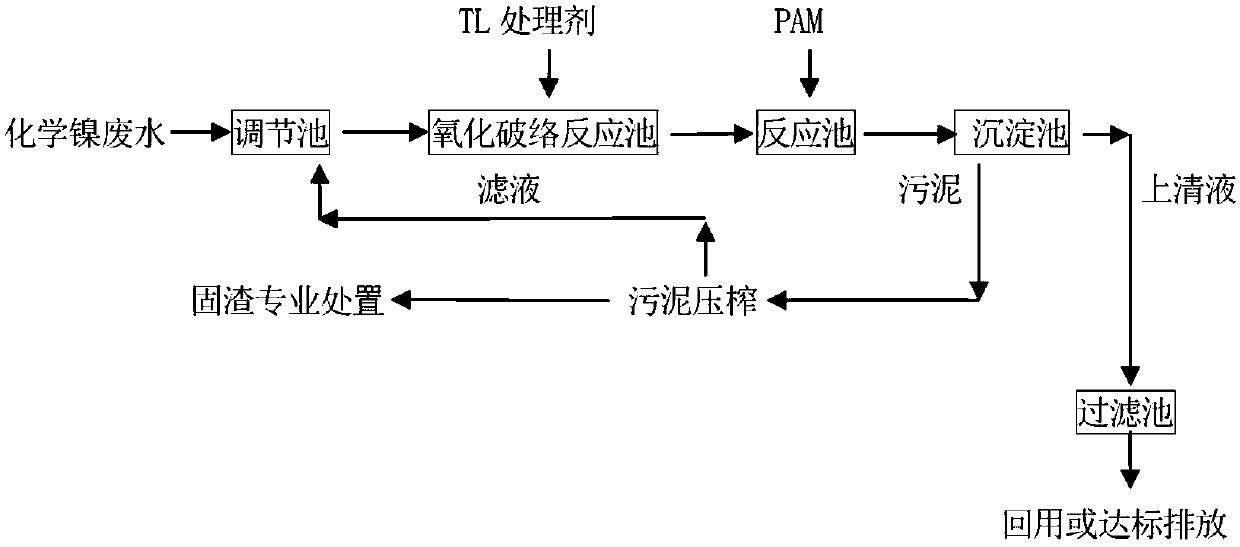

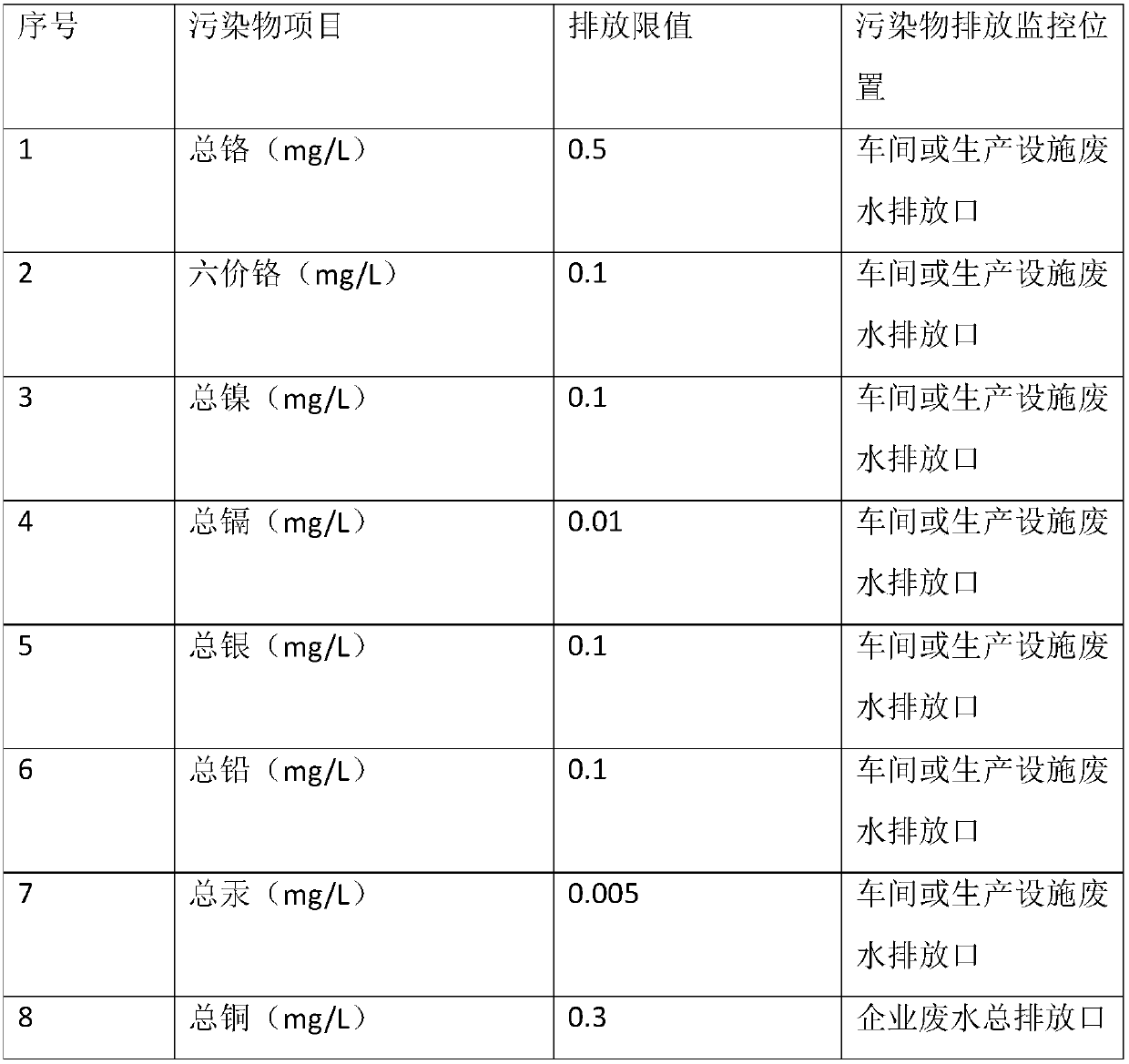

Chemical nickel waste water treating method

InactiveCN105884078AAchieve complete subsidenceAchieve settlementSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeWastewater

The invention provides a chemical nickel waste water treating method. The chemical nickel waste water treating method comprises the following steps: oxidizing a treating agent in a breaking reaction pond; aerating and stirring for reacting for 15-40 minutes; controlling the PH value to be 10-12; entering the reaction pond; adding a coagulant aid; precipitating in a settling pond; collecting supernatant; squeezing sludge in the settling pond; introducing squeezed filtrate into an adjusting pond; performing residue fixing treatment on the squeezed sludge, wherein the treating agent contains 70-90 percent by weight of alkaline matter and 10-30 percent by weight of oxidizing agent; the alkali substrate is one or more of NaOH, Na2CO3 and CaO; the oxidizing agent is H2O2 or / and Na2S2. By adopting the chemical nickel waste water treating method, complete precipitation of nickel ion and phosphorus is realized, the water quantity can reach the discharge standard in table 3 of GB21900_2008 Galvanized Pollutant Discharge Standard, and can stably reach the standard for a long time; the rate of reaching the standard is 99.9 percent or above.

Owner:漆雅丽 +1

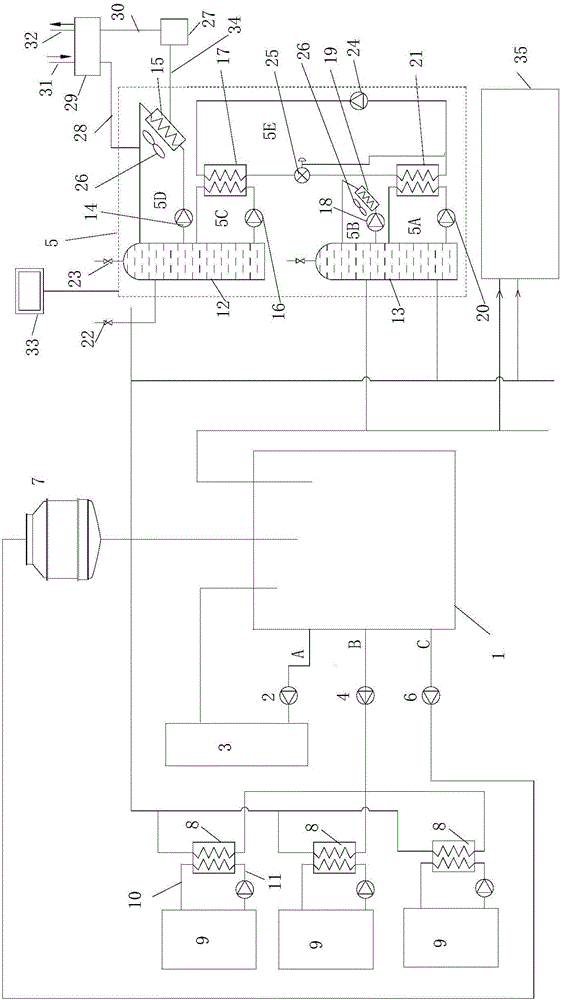

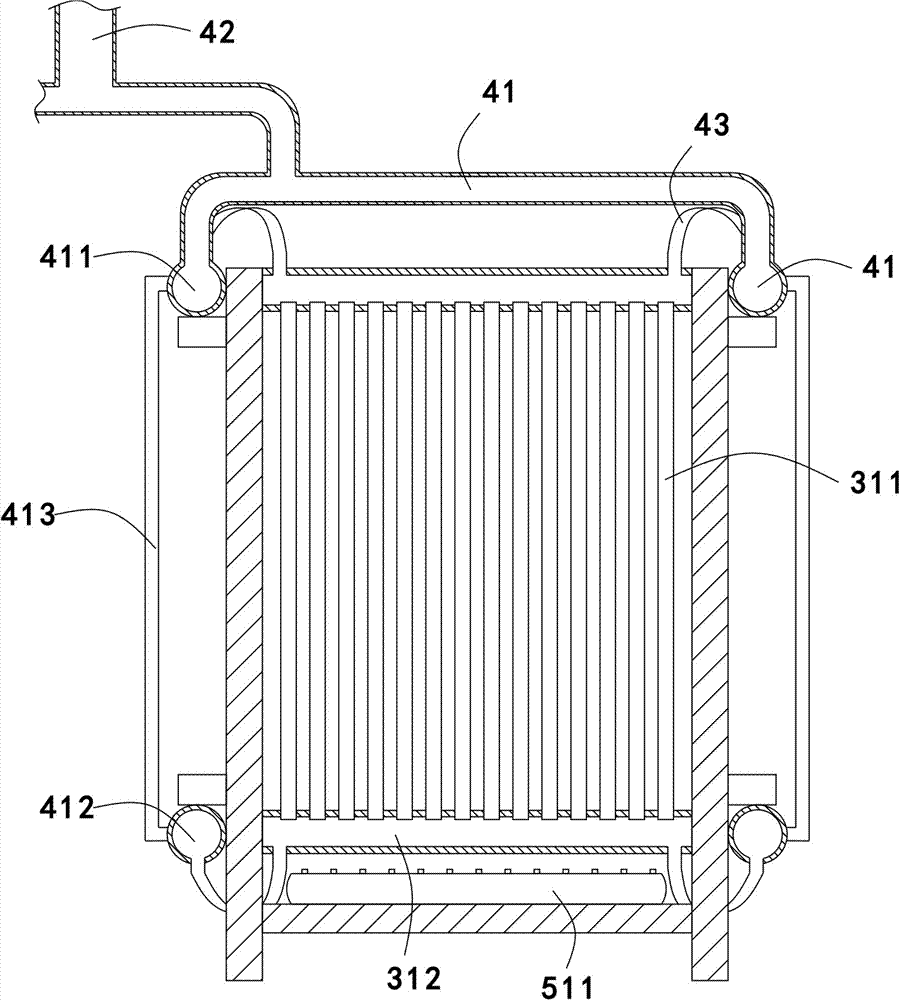

Cold and heat continuous supply system and method for cyclic recycling waste heat of cold utilization equipment

InactiveCN105716182ALess investment in facilitiesLess investmentFluid heatersSpace heating and ventilation detailsThermal energyWater storage

The invention discloses a cooling and heating continuous supply system and a cooling and heating continuous supply method for recycling and recovering waste heat from cold equipment, and belongs to the field of cold and heating continuous supply systems and cooling and heating heating methods for factory production. It includes a water storage tank, an auxiliary heating pipeline, a waste heat recovery pipeline, and a cooling pipeline; the auxiliary heating pipeline includes a first water pump and an auxiliary air heater connected sequentially through pipelines; the waste heat recovery pipeline includes The second water pump, the heat exchange device, and the air energy transducer, the water inlet of the second water pump is connected to the water storage tank, and the water outlet of the air energy transducer is connected to the water storage pool; the cooling pipeline includes a third water pump connected in sequence through pipelines ,Cooling Tower. The invention utilizes the plate heat exchanger to exchange the heat energy of the equipment into the water to form hot water, and transfers the heat energy in the hot water to the fresh air through the air energy transducer, and the fan blows the hot air to the heat-consuming equipment to use heat, and at the same time can provide The cold air is used for the cooling equipment; to realize the all-weather constant temperature water supply, save energy and reduce consumption, and use one thing for three purposes.

Owner:JIANGHUA HENGJIN PACKAGING MATERIAL CO LTD

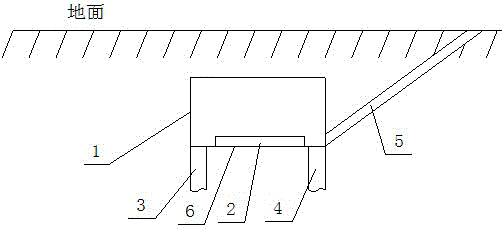

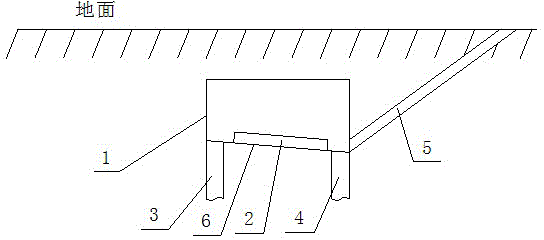

Energy-saving and environment-friendly natural fresh-keeping storehouse for fruit and vegetable

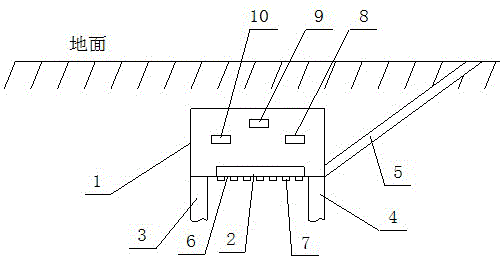

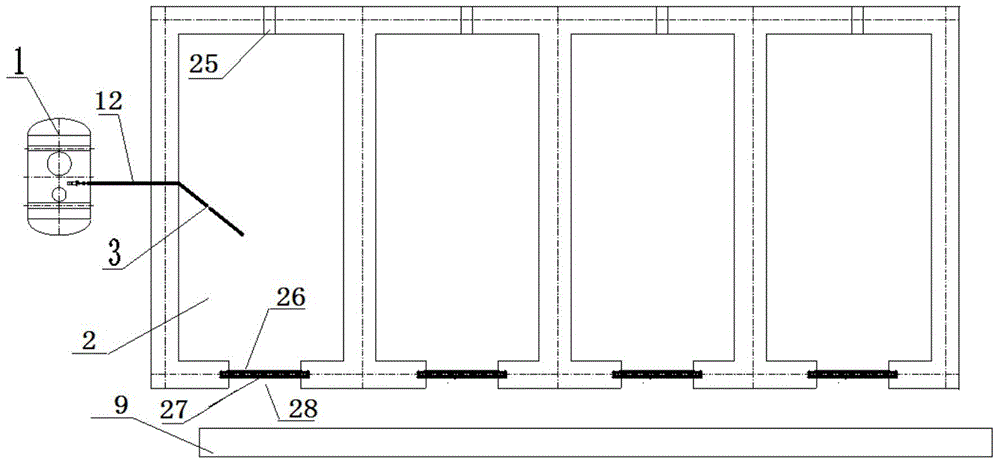

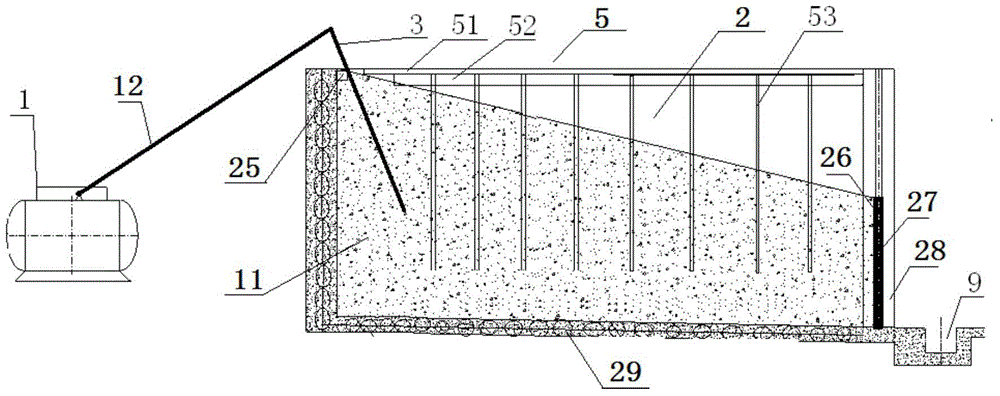

InactiveCN102845509AMoisturizing effect lasts and remains constantDelayed descent speedFood processingFruits/vegetable preservation by freezing/coolingHorticultureWater recovery

The invention discloses an energy-saving and environment-friendly natural fresh-keeping storehouse for fruits and vegetables. The fresh-keeping storehouse comprises a fruit and vegetable storage space 3-15 m from the ground surface; and the fruit and vegetable storage space is provided with a fruit and vegetable storage device, a cooling water collecting well and a cooling water recovery well. The fresh-keeping storehouse provided by the invention achieves low temperature, natural constant temperature, natural moisturizing and natural antibacterial effect with no or little rely on mechanical equipment, facilities and industrial energy, improves the storage quality of fruits and vegetables, prolongs the fresh-keeping storage period and is conducive to seasonal, spatial off-season and busy season surplus and deficiency regulation and marketing of fruits and vegetables.

Owner:四川省安岳县柠都柠檬科技开发有限公司

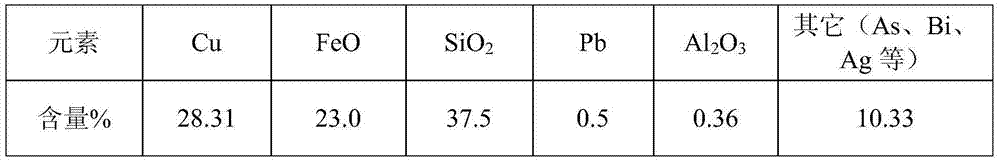

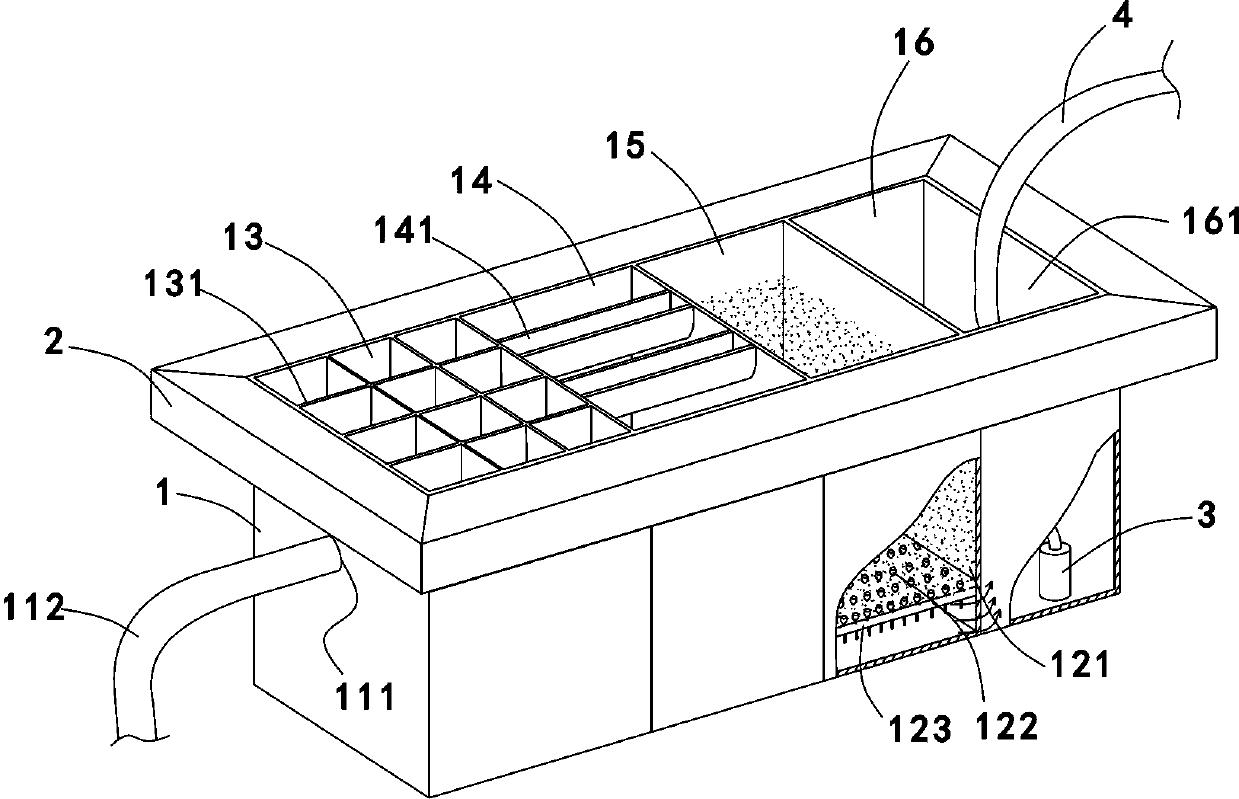

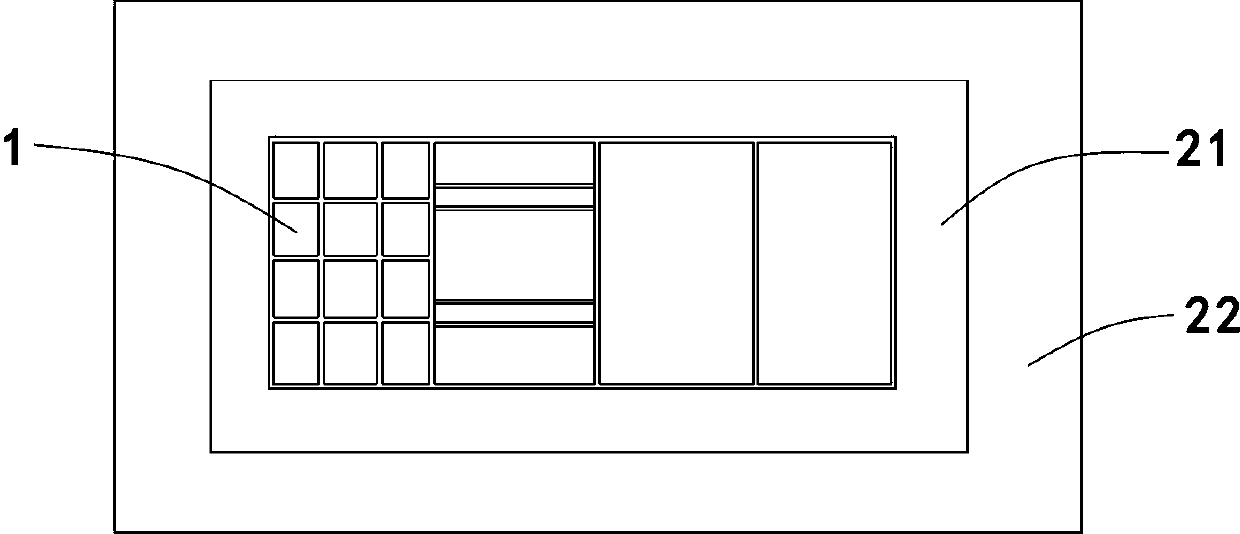

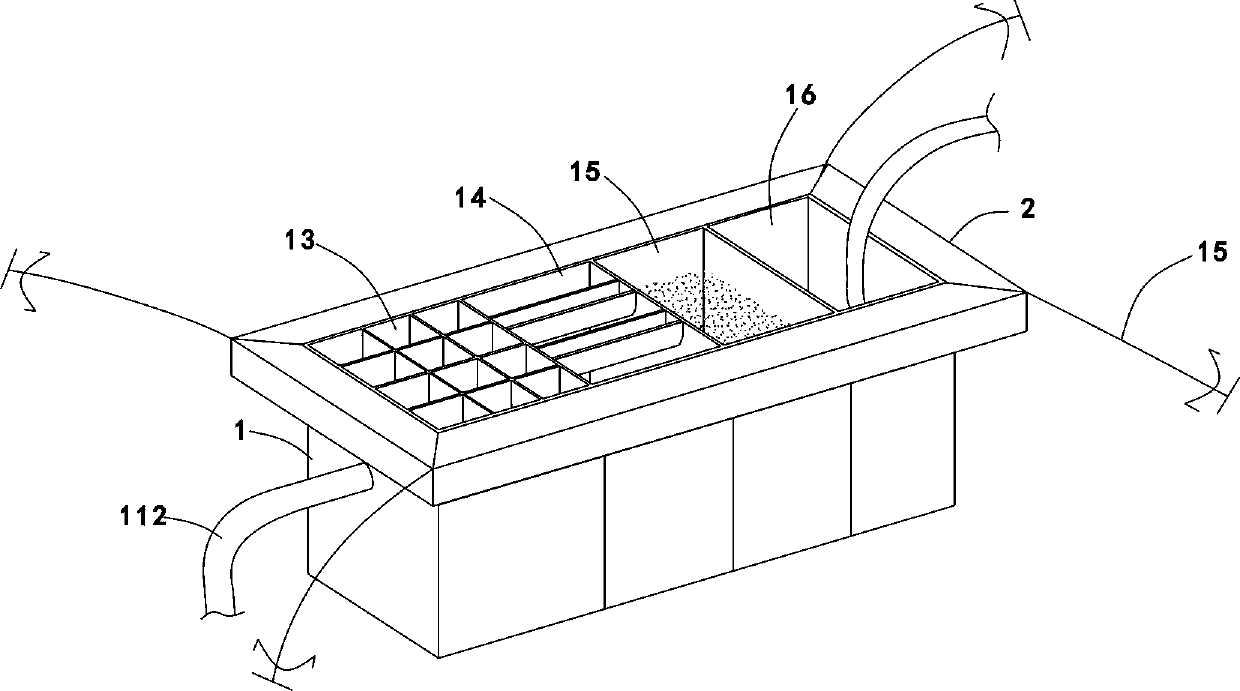

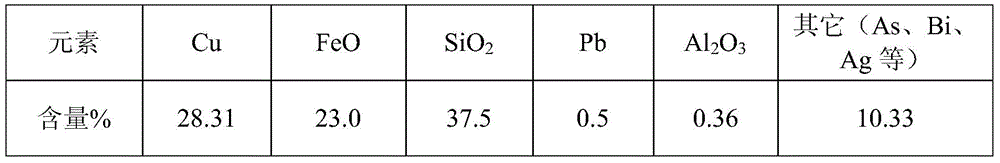

Method for carrying out mixed melting on multisource complex low-grade copper ores to produce white matte

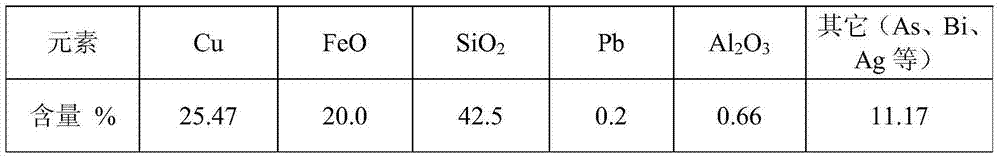

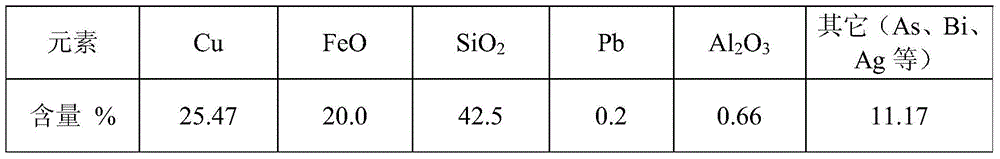

ActiveCN104232925AAchieve recyclingLess investment in facilitiesProcess efficiency improvementSlagPyrite

The invention discloses a method for carrying out mixed melting on multisource complex low-grade copper ores to produce white matte. The method comprises the following steps: carrying out batching according to a mass ratio of copper content of copper concentrates to copper content of scrap copper to copper content of refining slags of copper pyrites of 1:(0.30 to 0.45):(0.002 to 0.006); adding the copper concentrates, the scrap copper and the refining slags of the copper pyrites into a melting furnace; adding anthracite of which mass accounts for 5 percent to 19 percent of the total mass of the copper concentrates, the scrap copper and the refining slags of the copper pyrites into the melting furnace; melting in the oxygen-enriched air to produce the white matte. The method disclosed by the invention has a small investment scale, is low in energy consumption, continuously operates and can implement recycling of copper resources.

Owner:JIYUAN XINXIN INDAL +1

Method for cultivating blanched garlic leaves in trenches

InactiveCN102919008ALess investment in facilitiesImprove yield and qualityHorticultureCropGreenhouse

The invention discloses a method for cultivating blanched garlic leaves in trenches, which is characterized by comprising the technological processes of carrying out trenching by using idle land in winter, seed selection, seeding time selection, garlic seed processing, trench baking, garlic placing, shading softening, management and harvesting. The method disclosed by the invention solves the problems that shading tents and shading facilities are high in building investment cost and long in idle time in greenhouse vegetable production, and improves the multiple crop index of farmland; and the method is an effective way of increasing the income of farmers in farm slack seasons such as winter and spring, and is suitable for cultivating by the farmers.

Owner:宋永法

Cultivation technology of straw mushroom

InactiveCN104396568AEasy to operateOperational securityCultivating equipmentsMushroom cultivationHigh survival rateMushroom

The invention discloses a cultivation technology of straw mushroom. The cultivation technology comprises the following steps: (1) preparing a culture medium; (2) inoculating in an open way; (3) growing rapidly; (4) removing bags and covering with soil; (5) managing fruiting and harvesting. According to the technology, mature material bag cultivation and open inoculation are adopted, and the sterile condition for inoculation of the straw mushroom is effectively guaranteed; the technology has the characteristics of flexibility in production, low cost, high survival rate and environmental friendliness and health of products.

Owner:FUSHUN COUNTY YUANYE MUSHROOM DEV

Method for producing white matte by mixed smelting of copper refining slags-pyrite-bornite tailings

The invention discloses a method for producing white matte by mixed smelting of copper refining slags-pyrite-bornite tailings. The method comprises the following steps of: preparing materials according to the mass ratio of the copper contents of the copper refining slags, the pyrite and the bornite tailings being 1:(0.006 to 0.01):(0.02 to 0.09), adding the copper refining slags, the pyrite and the bornite tailings to a smelting furnace, adding anthracite which accounts for 5% to 19% total mass of the copper refining slags, the pyrite and the bornite tailings to the smelting furnace, and smelting in oxygen-enriched air to generate the white matte. The method for producing the white matte by the mixed smelting of the copper refining slags-pyrite-bornite tailings is small-scale in investment, low in energy consumption, continuous in operation and capable of recycling copper resources.

Owner:JIYUAN XINXIN INDAL +1

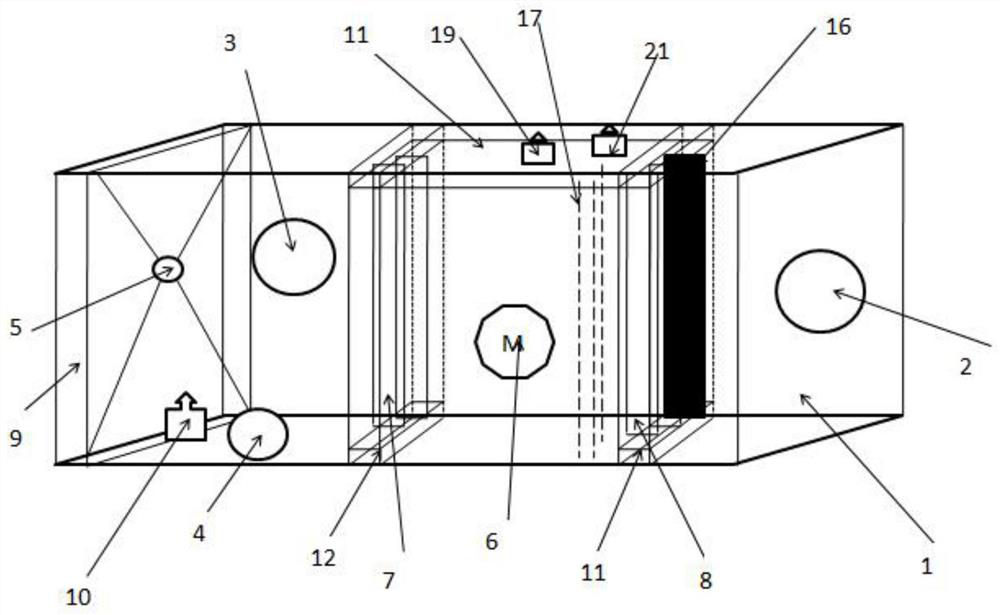

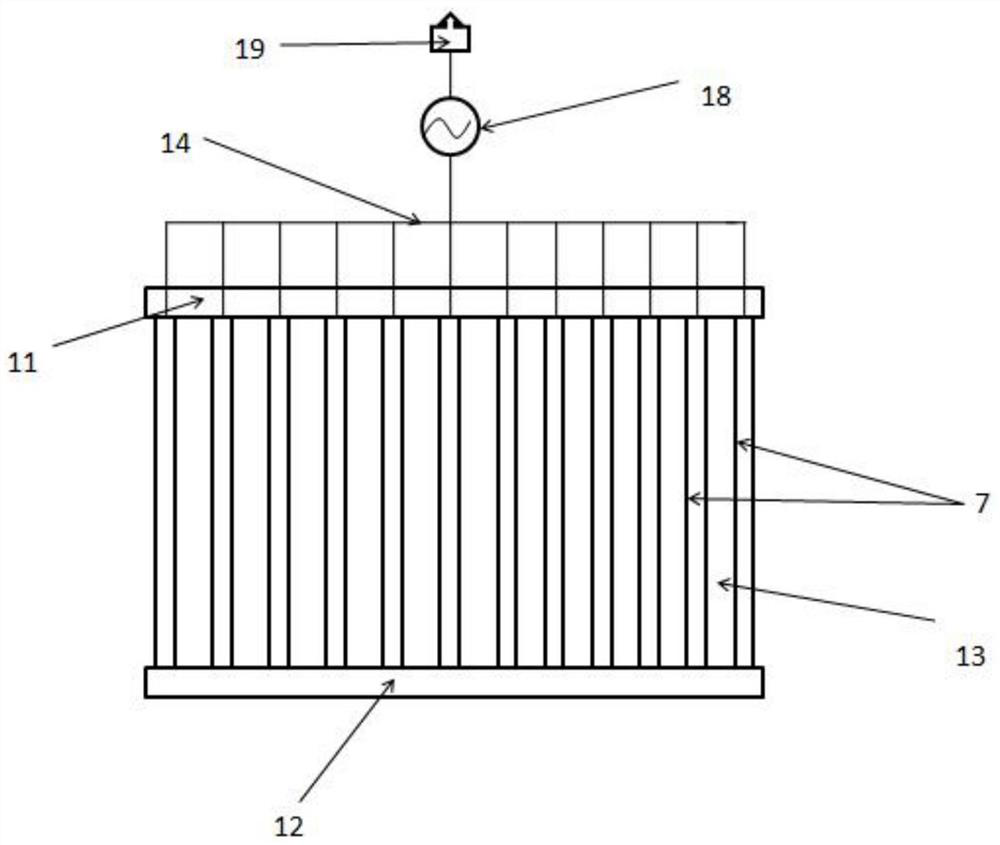

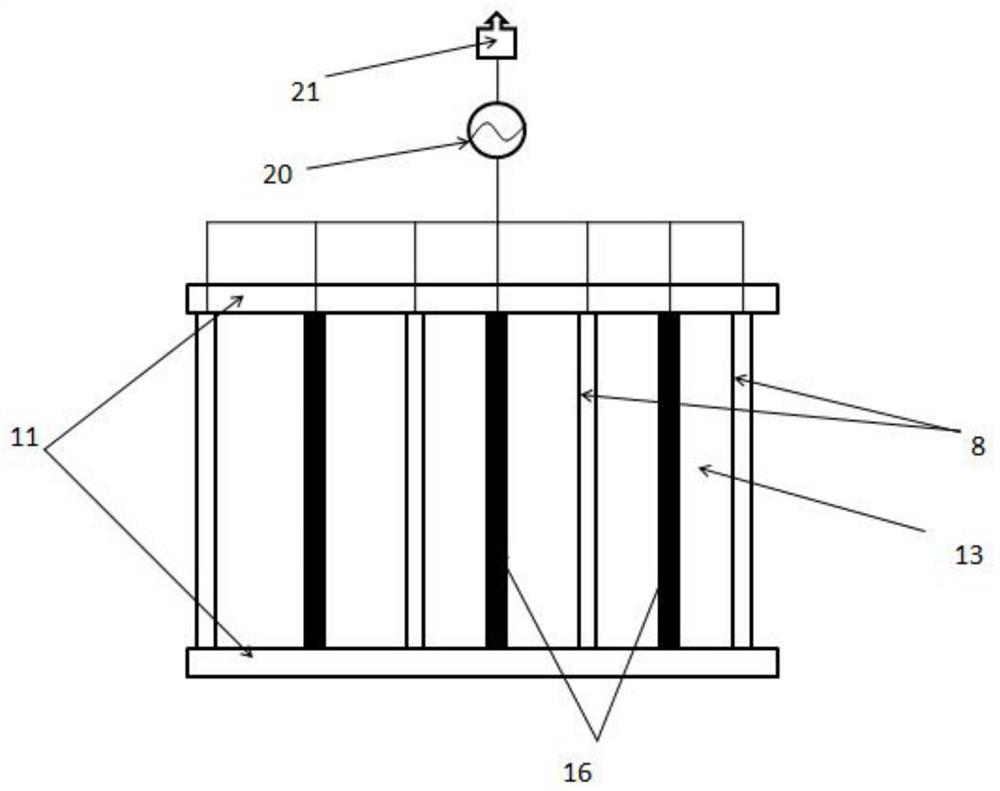

Plasma exhaust gas comprehensive processing device

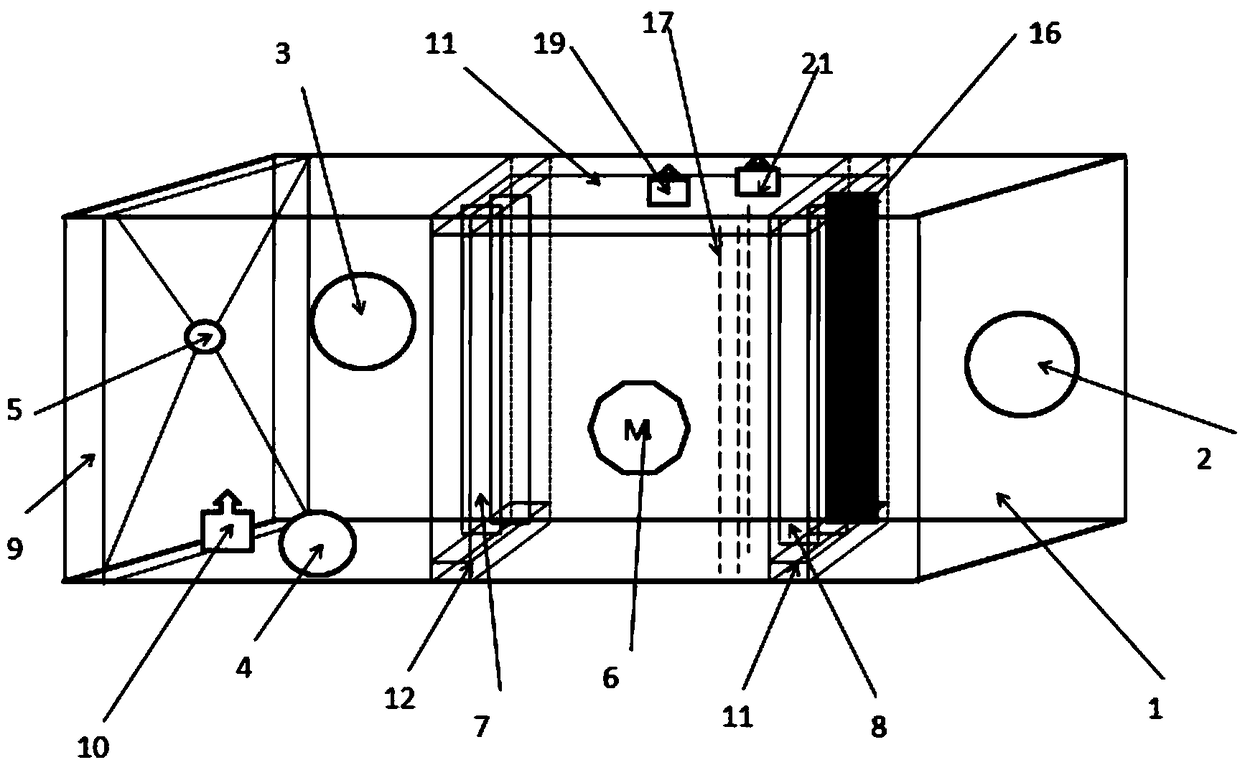

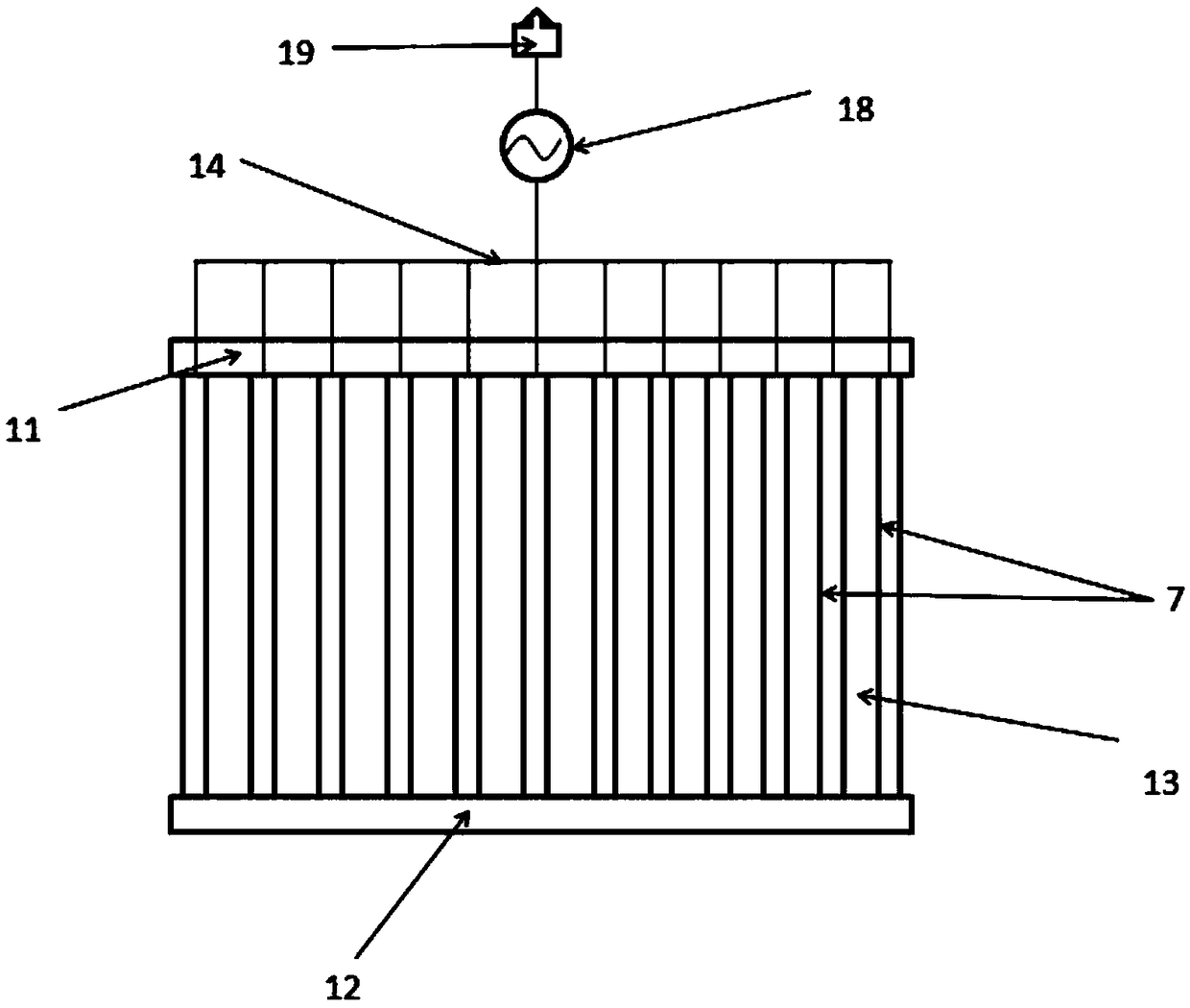

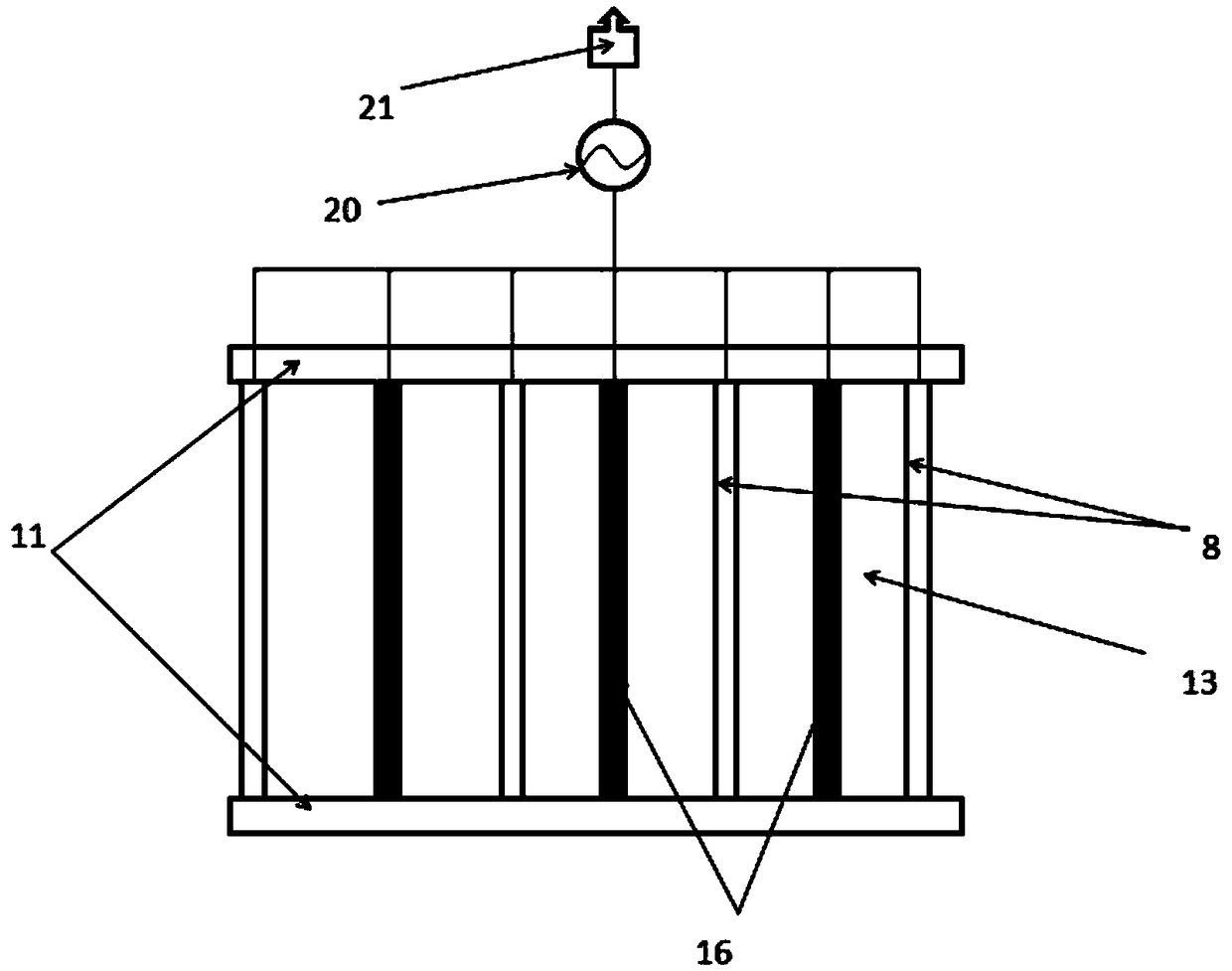

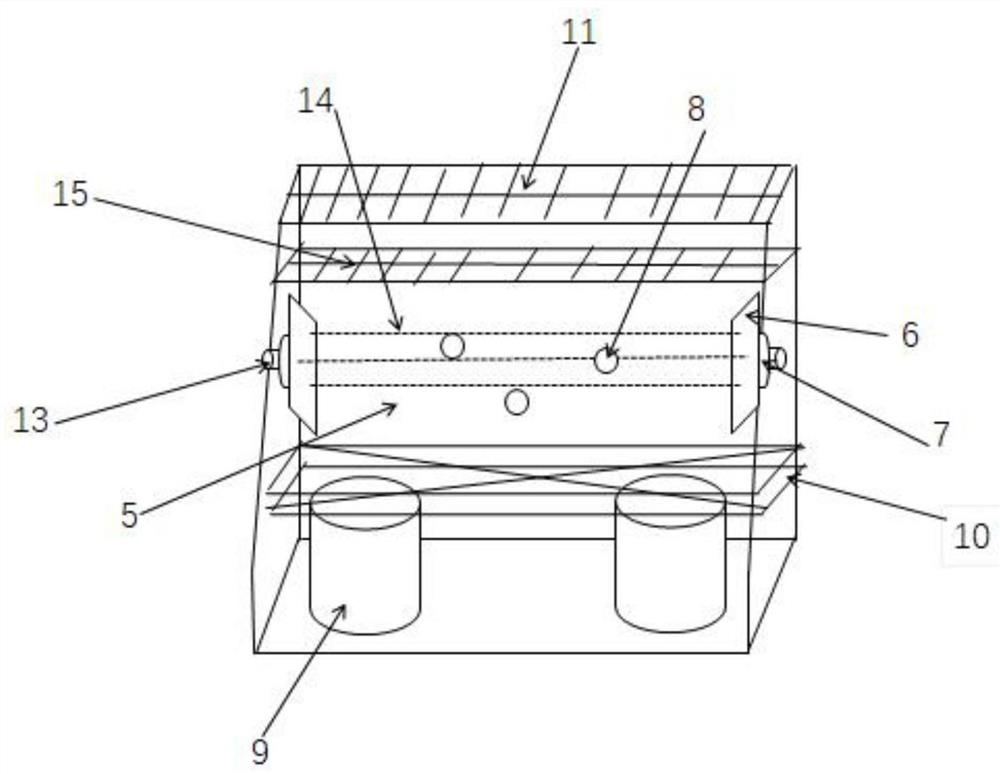

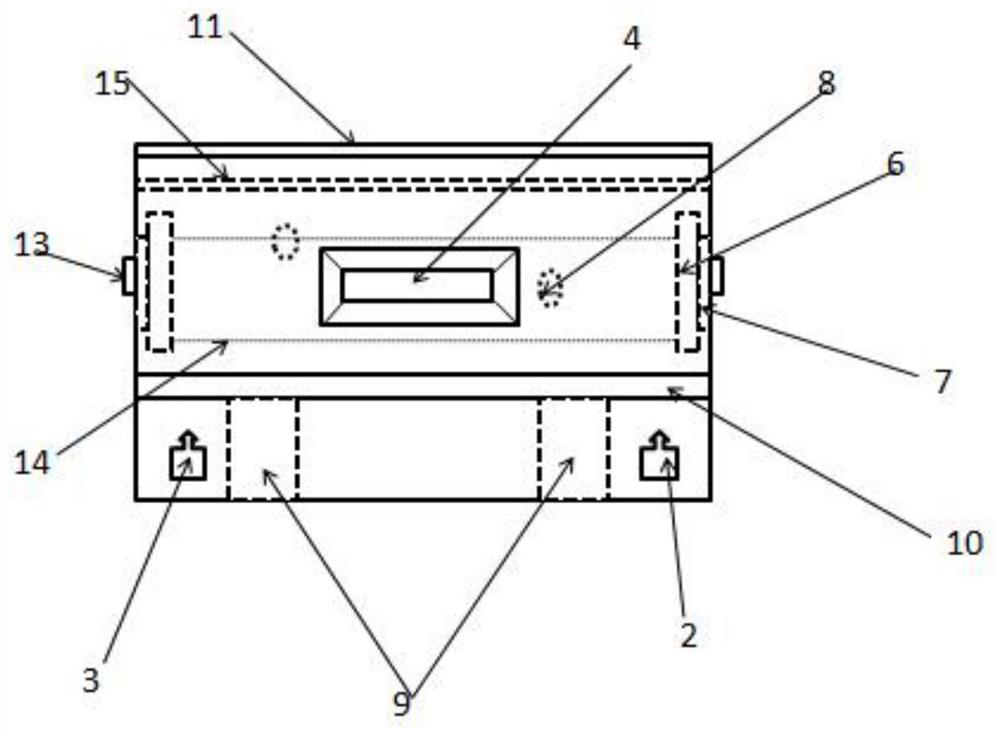

ActiveCN108283870AIncrease concentrationIncreased adsorption efficiencyGas treatmentElectrostatic separationElectricityLow voltage

The invention discloses a plasma exhaust gas comprehensive processing device, which comprises an insulating casing, a base, and a tungsten wire. The base is fixedly connected with the insulating casing, the base is provided with a water outlet, the top end of the insulating casing is provided with a gas inlet, a filter device is fixed in the middle portion of the inner cavity of the insulating casing, the filter device comprises electrodes, separators, ground electrodes and a low-voltage power source, the electrodes and the ground electrodes are electrically connected with the low-voltage power source through wires, gaps are arranged between the electrodes and the ground electrodes, and the electrodes and the ground electrodes are spaced apart. The top ends and the bottom ends of the electrodes and the ground electrodes are fixedly provided with the separators, and the separators are fixed on the inner wall of the insulating casing. The exhaust gas comprehensive processing device withautomatic electrode cleaning design has the advantages of simple structure, convenient operation and automatic cleaning.

Owner:ANHUI UNIV OF SCI & TECH

Method for treating, transforming and utilizing organic waste

InactiveCN108144945ASolve processing problemsFast and thorough decompositionFood processingSolid waste disposalSocial benefitsPre treatment

The invention belongs to the technical field of environmental protection, and particularly relates to a method for treating, transforming and utilizing organic waste. According to the method, the pre-treated organic waste is subjected to bio-abdominal transformation treatment through cockroaches, the cockroaches for treating the organic waste serve as protein feed for the cultivation industry, andmanure generated by the cockroaches serve as fertilizers. By adopting the method for treating, transforming and utilizing the organic waste, other energy sources are not consumed, secondary pollutionof three wastes of the waste water, the waste gas and the industrial residue is avoided in the treatment process, the treatment difficult problem of the organic waste is effectively solved, the transformation cost is low, benefits are high, and social benefits are remarkable.

Owner:山东鲲鹏农业发展有限公司

A comprehensive treatment device for plasma waste gas

ActiveCN108283870BIncrease concentrationIncreased adsorption efficiencyGas treatmentElectrostatic separationLow voltageExhaust fumes

The invention discloses a plasma exhaust gas comprehensive processing device, which comprises an insulating casing, a base, and a tungsten wire. The base is fixedly connected with the insulating casing, the base is provided with a water outlet, the top end of the insulating casing is provided with a gas inlet, a filter device is fixed in the middle portion of the inner cavity of the insulating casing, the filter device comprises electrodes, separators, ground electrodes and a low-voltage power source, the electrodes and the ground electrodes are electrically connected with the low-voltage power source through wires, gaps are arranged between the electrodes and the ground electrodes, and the electrodes and the ground electrodes are spaced apart. The top ends and the bottom ends of the electrodes and the ground electrodes are fixedly provided with the separators, and the separators are fixed on the inner wall of the insulating casing. The exhaust gas comprehensive processing device withautomatic electrode cleaning design has the advantages of simple structure, convenient operation and automatic cleaning.

Owner:ANHUI UNIV OF SCI & TECH

Biogas slurry harmless treatment and resource utilization technology for large-scale pig farm

InactiveCN108358389AAchieving processing powerRealize comprehensive utilizationTreatment using aerobic processesClimate change adaptationPig farmsResource utilization

The invention relates to a biogas slurry harmless treatment and resource utilization technology for a large-scale pig farm. The biogas slurry harmless treatment and resource utilization technology comprises the following steps: firstly, collecting manure in a livestock pig farm by using dry collection and carrying out solid-liquid separation; secondly, putting biogas slurry in the first step intoa special conical reactor of a pretreatment system for carrying out adsorption treatment through a sewage draining passage; thirdly, feeding the biogas slurry treated in the second step into an aerobic system for carrying out biochemical treatment; fourthly, detecting the liquid obtained in the third step; if the liquid meets the Livestock And Poultry Breeding Wastewater Discharge Standard GB18596-2001, COD is smaller than or equal to 150mg / l, BOD is smaller than or equal to 400mg / l and ammonia-nitrogen is smaller than or equal to 80mg / l, recovering the liquid for fertilizer utilization. The biogas slurry harmless treatment and resource utilization technology disclosed by the invention has the advantages that the conical reaction kettle and the aerobic system are adopted, so that the investment of facilities can be greatly reduced; meanwhile, pollution factors in the biogas slurry in the pig farm are removed through adsorption; the biogas slurry subjected to adsorption treatment undergoes biochemical treatment by the aerobic system; the treated liquid accords with the Livestock And Poultry Breeding Wastewater Discharge Standard, so that the liquid can be recovered for fertilizer utilization.

Owner:南通华多种猪繁育有限公司

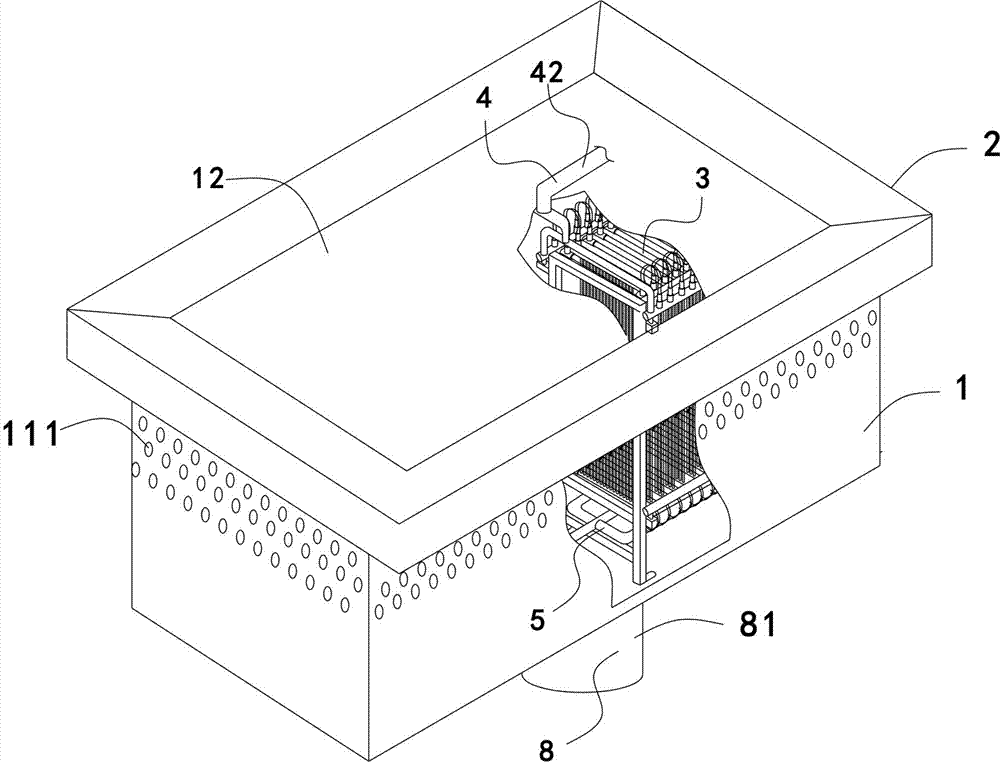

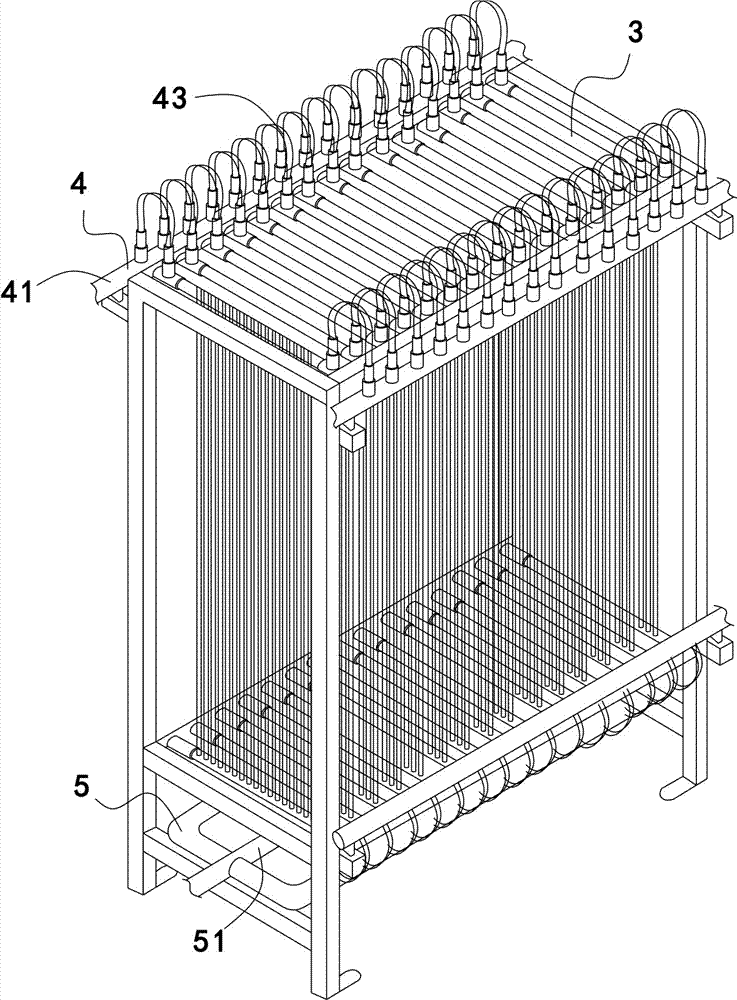

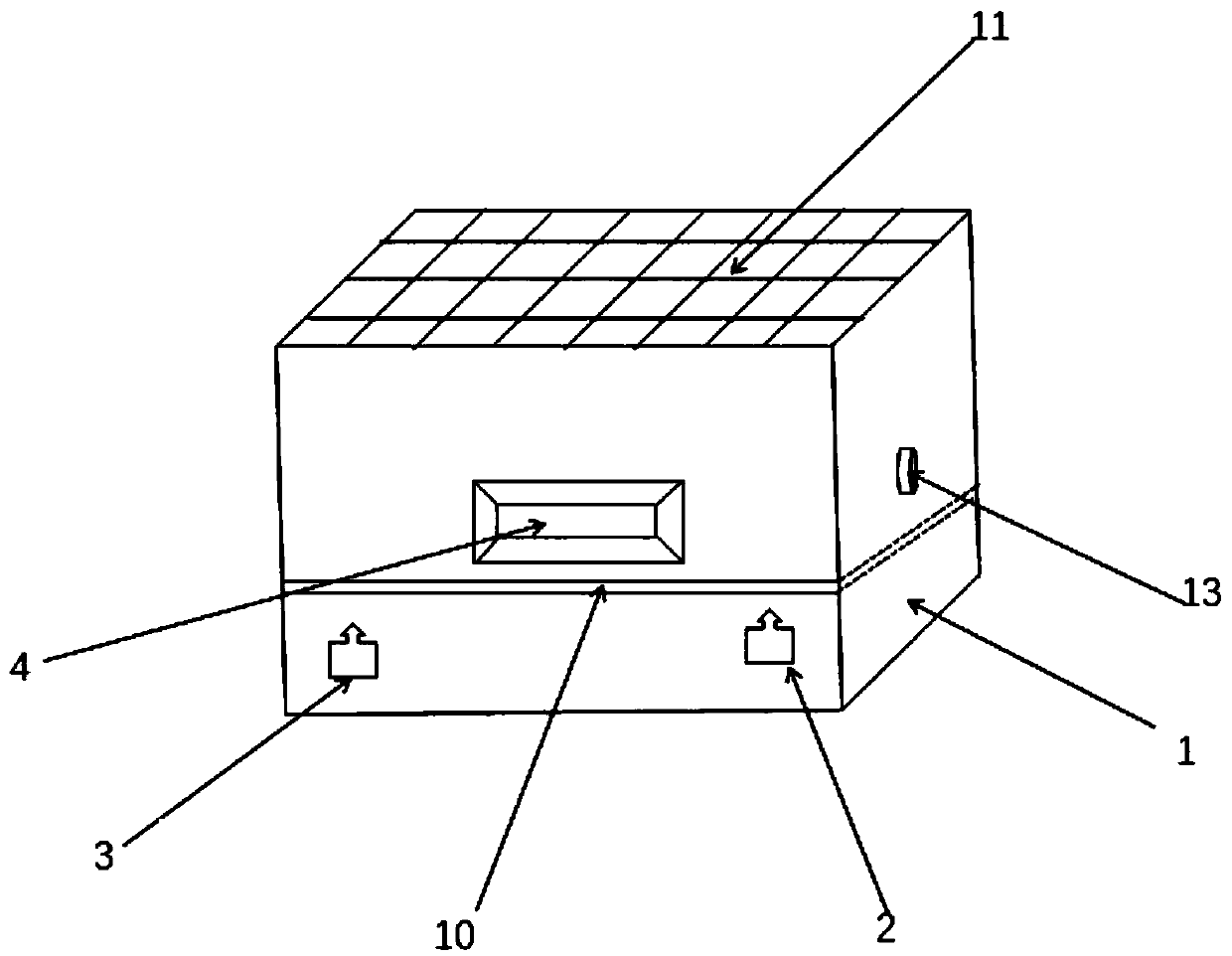

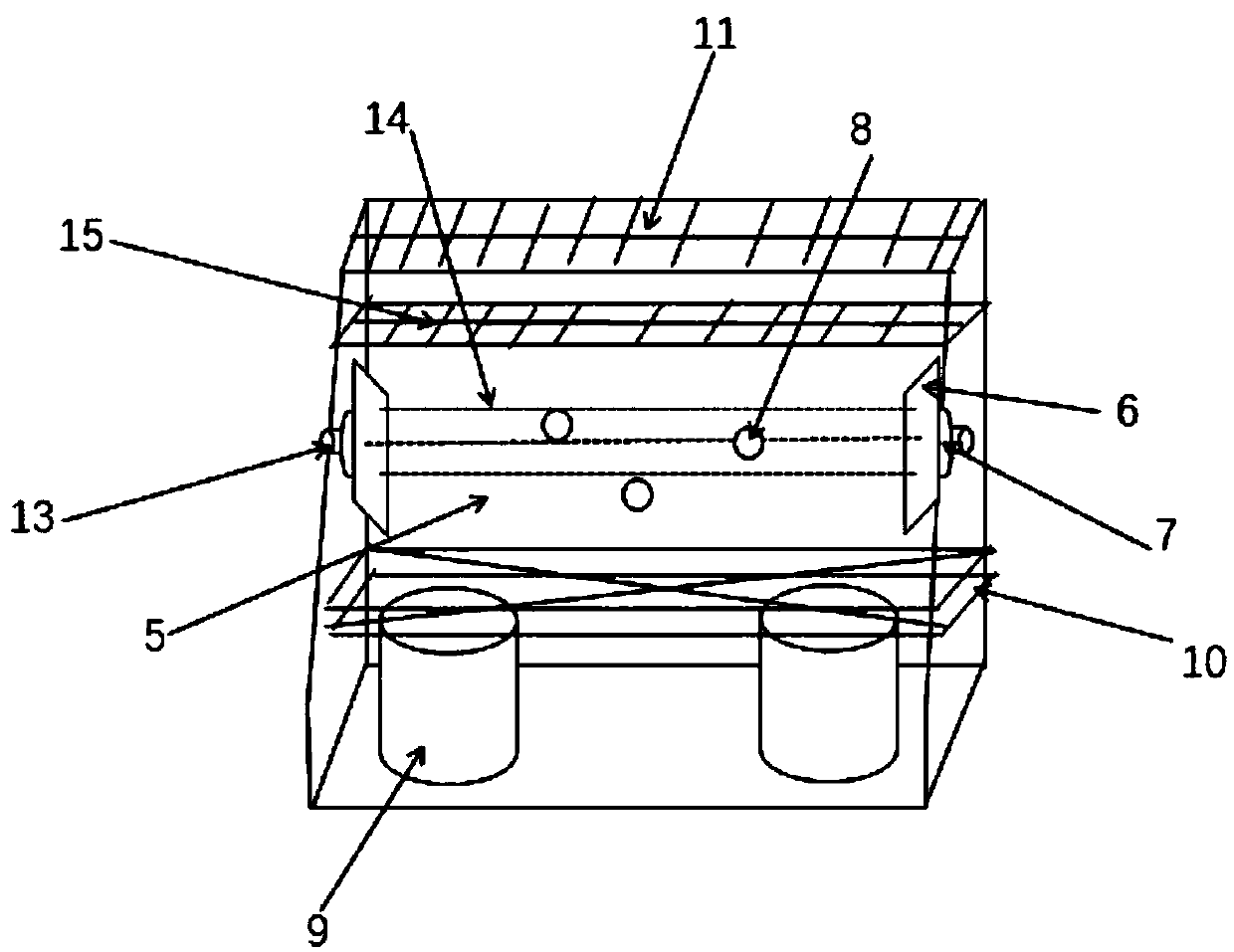

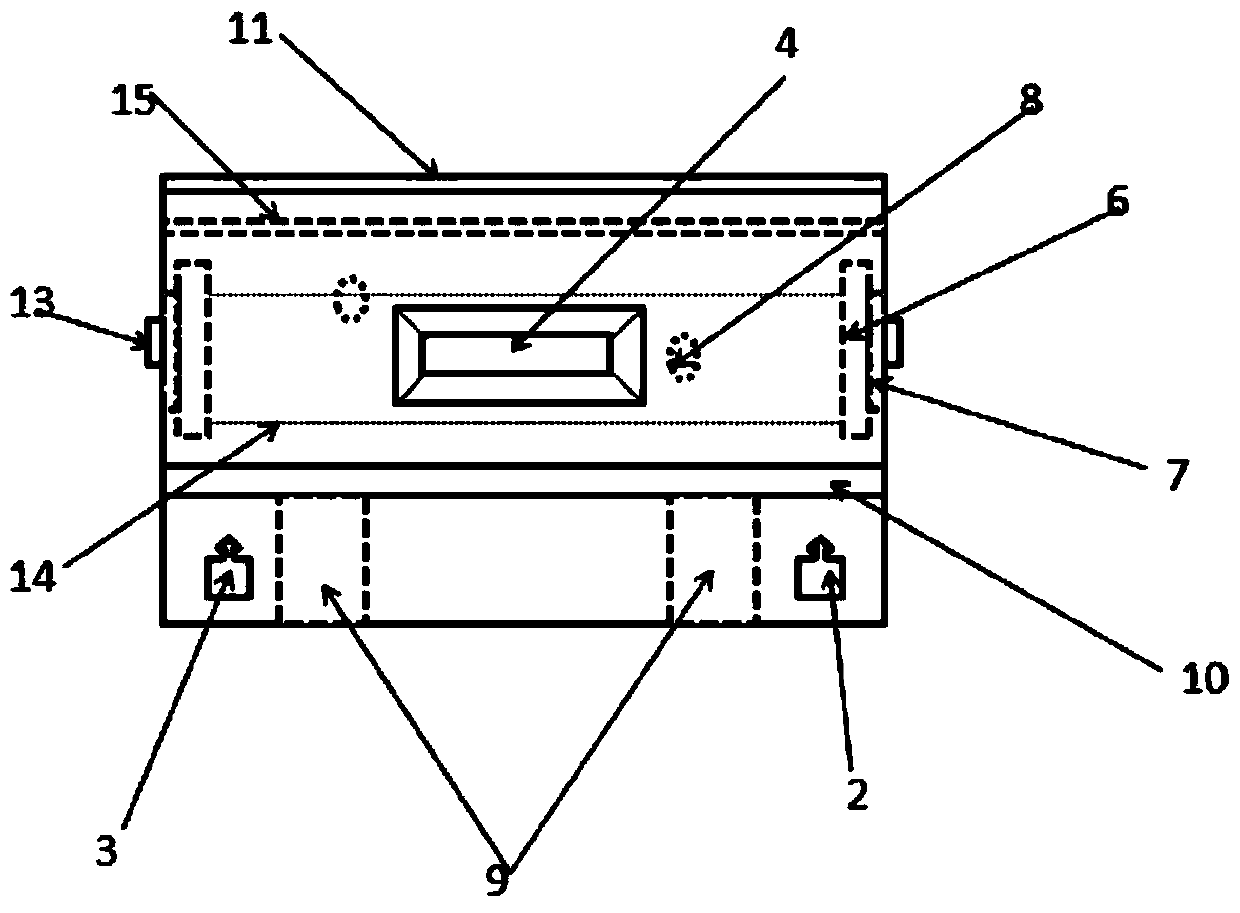

Submersible type water purifying system

InactiveCN106865739AImprove resource utilizationSave land resourcesSpecific water treatment objectivesBiological treatment apparatusWater treatmentWater source

The invention discloses a submersible type water purifying system, comprising a box body. At least a part of the box body is arranged in a water body of a water source; the water source comprises rivers, lakes, riverways, brooks, reservoirs, non-drinking water in the riverways and wastewater; the box body is internally provided with a water processing module, and the water processing module comprises multiple sets of membrane components for purifying the water body, a clear water output unit for outputting purified water and a membrane washing unit for washing the membrane components. The submersible type water purifying system can be arranged in the water body, does not need to occupy a land source, and thus saves a large quantity of land source; and the system can be assembled through assembly and then put into use; the production and construction periods are short; and the operating cost is lowered greatly.

Owner:ZHEJIANG LIANCHI WATER EQUIP

Death pig housefly larvae ecological treatment method

InactiveCN104907313AEfficient killingIncrease oxygen contact surfaceSolid waste disposalResource utilizationHousefly

The invention provides a death pig housefly larvae ecological treatment method. The method realizes complete resource utilization of death pigs. The method comprises the following steps of immersing a death pig in boiling water, adding a proper amount of mushroom bran into the death pig to obtain a death pig culture material for housefly larvae cultivation, inoculating the death pig culture material with incubated housefly larvae according to a certain ratio, carrying out culture for 3-4 days to obtain mature housefly larvae, collecting the mature housefly larvae as a protein forage raw material, carrying out further compost fermentation on the collected residue, carrying out air drying to greatly reduce moisture, and carrying out crushing to obtain the products which can be directly used as nutrient-rich biological-organic fertilizer. The method realizes efficient and fast treatment on death pigs, has no latent biosafety problems, does not product secondary pollution, has a low investment cost and has high integrated economic benefits.

Owner:LESHAN NORMAL UNIV

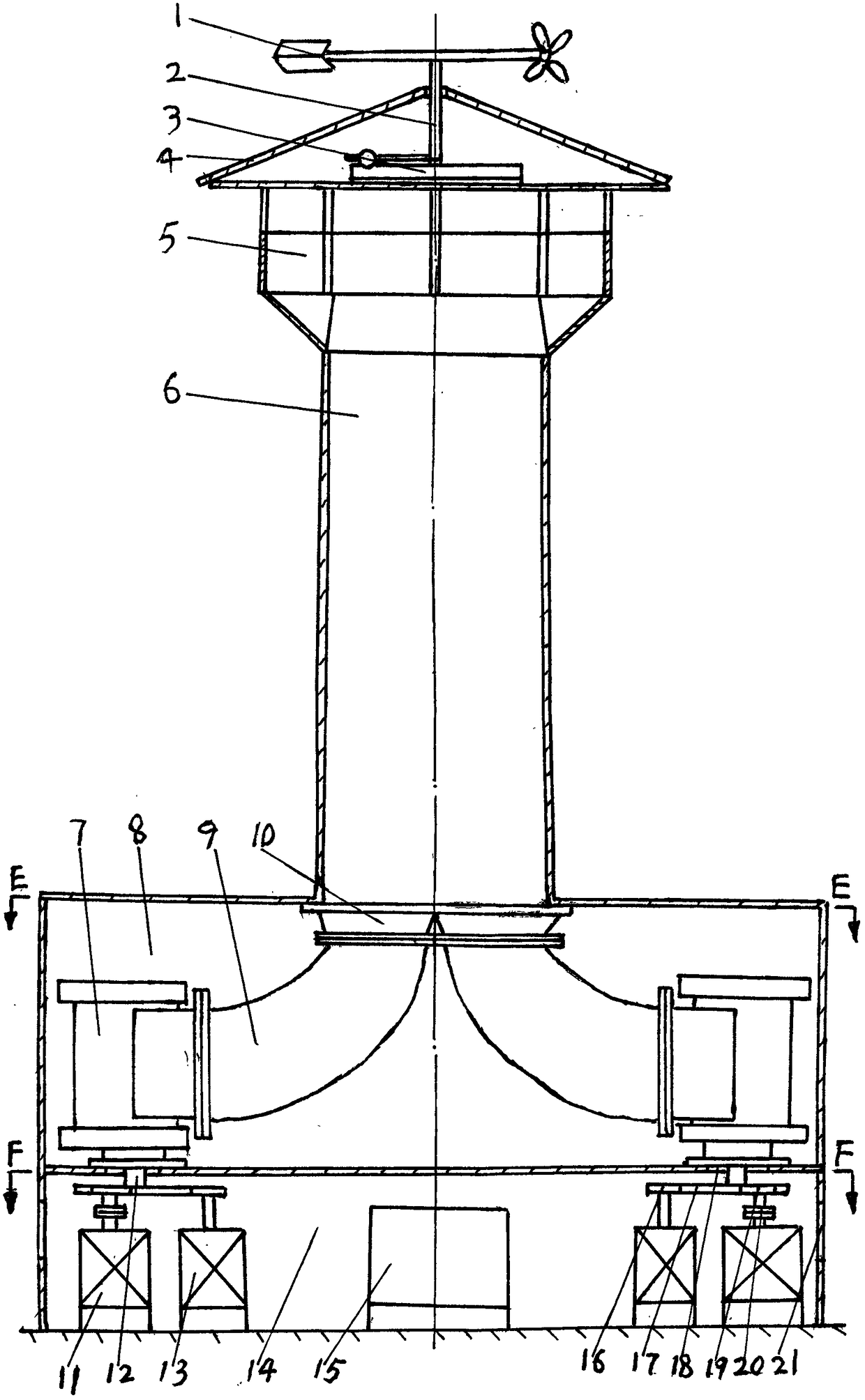

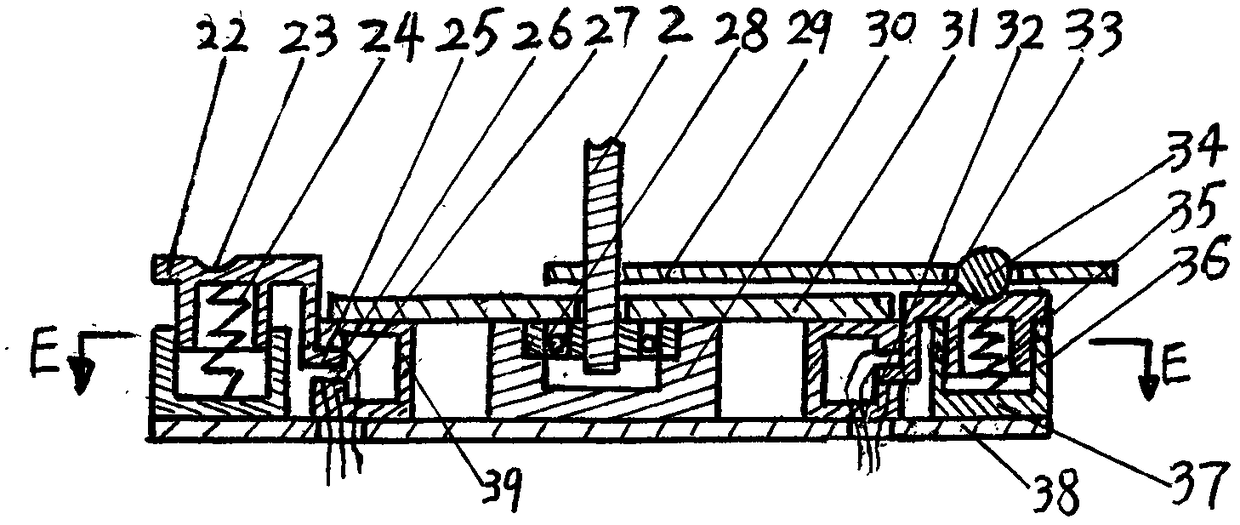

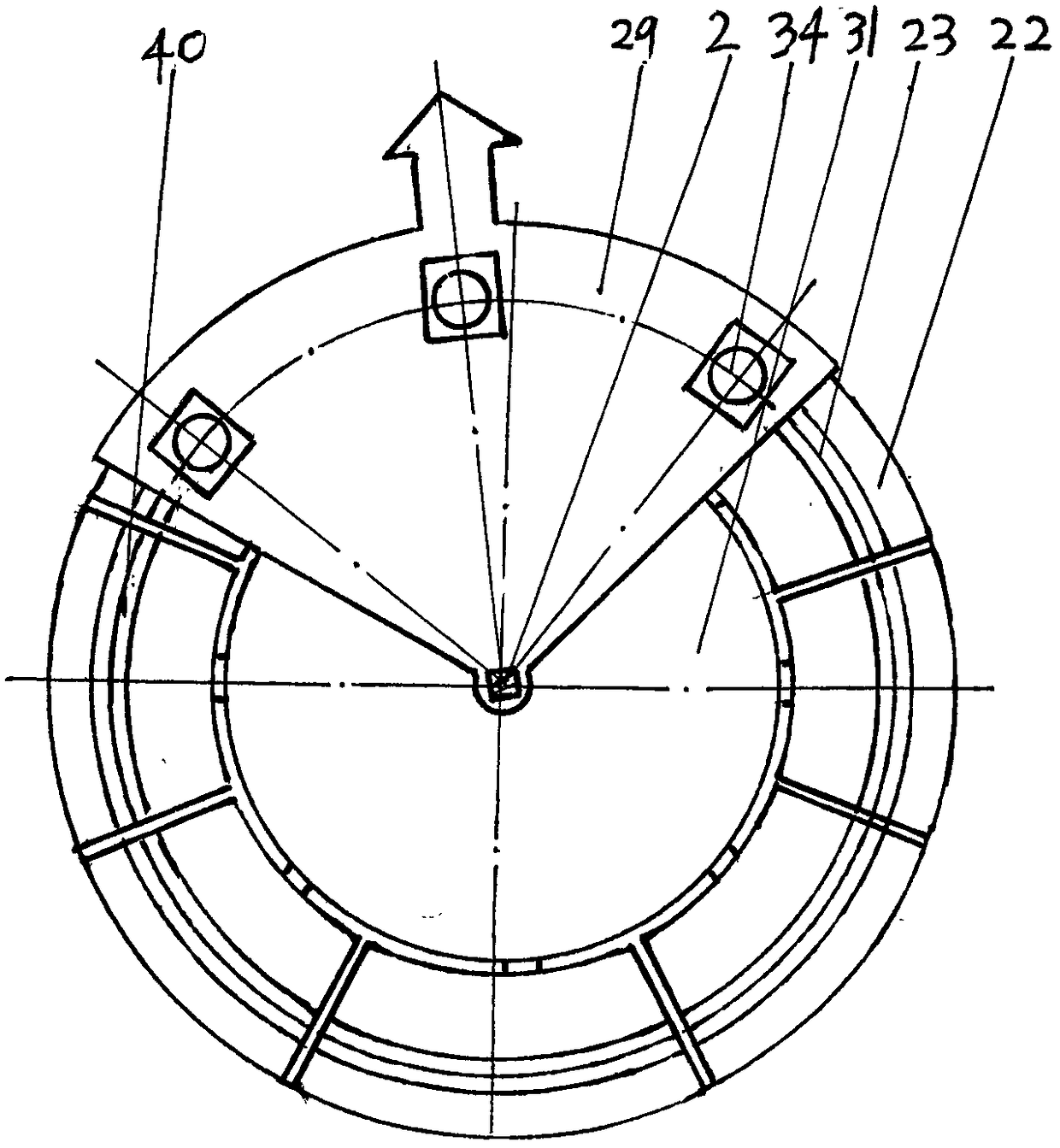

Cross-flow type super rotary jetting wind power station

ActiveCN108691729AEasy to manufactureReduce manufacturing costWind energy with electric storageFinal product manufactureAutomatic controlElectricity delivery

The invention discloses a cross-flow type super rotary jetting wind power station. A brand new wind power generation mode is provided. A wind indicator and an automatic wind tracking device are used for automatically controlling a wind inlet pavilion to automatically track the wind direction and collect airflow, the airflow collected by the wind inlet pavilion at high altitude is drained to the ground through a wind inducing building, a jetting ring inside a rotary jetting machine with the brand new drive principle is adopted, airflow which is rotationally jetted from the jetting ring pushes apower wheel to rotate, the power wheel rotates to drive a spindle of the rotary jetting machine to rotate, finally, the rotating spindle of the rotary jetting machine is accelerated by a gear to drive a power generator to rotate at a high speed and generate power, and current is adjusted by a storage battery. Compared with existing wind power generation modes, the cross-flow type super rotary jetting wind power station is the subversive revolution, the cost on the aspects of manufacturing, mounting, transportation, management, power conveying and the like is far lower than that of the existing wind power generation modes, the wind power generation efficiency is far higher than that of the existing wind power generation modes, the cross-flow type super rotary jetting wind power station isnot limited and can be built at any place to generate power, and electric energy which is easy to obtain and endless and is extremely cheap and environmentally friendly will completely lead human beings to the future energy revolution.

Owner:余四艳

A kind of potato starch wastewater treatment process

ActiveCN108947116BImprove water qualityLess investment in facilitiesWater contaminantsTreatment involving filtrationFlocculationPotato starch

The invention relates to the technical field of starch wastewater treatment, and particularly relates to a treatment process for potato starch production wastewater. Starch extraction wastewater is pretreated by addition of an acidity regulator, flocculation lumps are formed; and a part of the flocculation lumps is precipitated at the bottom of a flow tank during flowing; the wastewater is naturally placed in a wastewater collection tank for more than 120 days, and then enters a wastewater filter tank for performing filtration treatment; a flocculant is added, precipitation is performed for 2-3 hours after stirring; and the wastewater after flocculation treatment enters an anaerobic system and an aerobic biochemical system in order to further purify the water quality to meet a discharge standard. Objects of the potato starch wastewater treatment process are to solve the problem of wastewater treatment in small and medium-sized potato starch, and to solve the problems of large investment, long start-up period, waste of waste water resources, non-standardized water discharge and high operation cost of sewage treatment equipment in a wastewater treatment process.

Owner:南阳市固德威机械装备有限公司

Discharge plasma assisted combustion energy-saving and environment-friendly oven

ActiveCN107928442AAvoid pollutionGreat tasteClimate change adaptationRoasters/grillsCo2 absorptionPollutant emissions

The invention discloses a discharge plasma assisted combustion energy-saving and environment-friendly oven which includes an insulating casing and a charcoal chamber. A baffle and a bracket are arranged on the lower portion of the charcoal chamber. The top of the charcoal chamber is provided with a tungsten net and a barbecue grill. High-voltage electrodes are arranged on both sides of an insulating shell in the charcoal chamber, and a sliding groove is formed between a lifting control device and the insulating shell. The high-voltage electrodes inside the charcoal chamber are connected with aregulating device through a high voltage wire. A carbon dioxide absorption and extinguishing device is connected with a gas inlet and outlet hole. The voltage is regulated to control charcoal flames,charcoal can also fully burn in oxygen-depleted areas, and carbon dioxide is absorbed. Electric energy is fully utilized, a fire is uniform, smoke-free barbecue is achieved, the discharge plasma assisted combustion energy-saving and environment-friendly oven enables foods to be rich in active materials and better in taste; the pollutant emission is less, and the oven is safe and reliable.

Owner:ANHUI UNIV OF SCI & TECH

Method for producing white matte by mixed smelting of scrap copper and copper concentrate

InactiveCN101845555BLarge amount of processingReduce the amount of fuelProcess efficiency improvementSmelting processCopper

The invention relates to a process for producing white matte by mixed smelting of scrap copper and copper concentrate. Based on the traditional matte smelting process, the materials are mixed according to the mass ratio of the copper content of copper concentrate and scrap copper of 1:0.5-0.25, and the scrap copper is continuously added into a melting furnace; and coal the amount of which is 2% to 9% of the amount of the copper concentrate is added, and the white matte is produced by smelting in oxygen-enriched air with the volume concentration of 60% to 95%. The process of the invention has the advantages of low investment, low energy consumption, simple implementation, convenient operation, energy saving, environmental protection and the like, can effectively treat scrap copper, produces white matte, can reduce the copper content in slag, and overcomes the shortcomings that the copper content in the slag is high in the traditional high-grade matte smelting method.

Owner:XIZHI ELECTRONICS MATERIALS BRANCH YUNNAN COPPER IND GRP +3

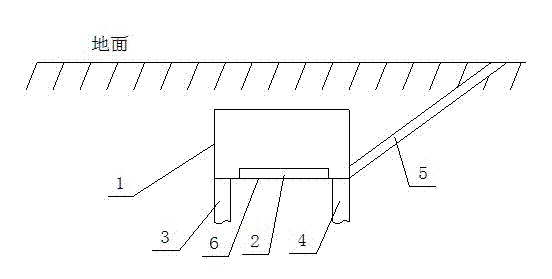

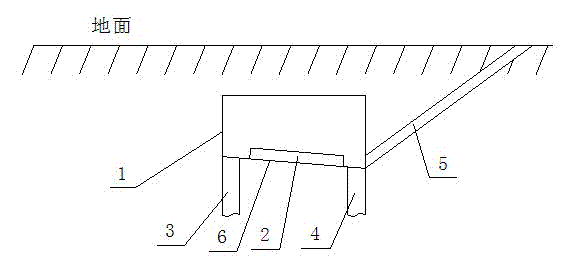

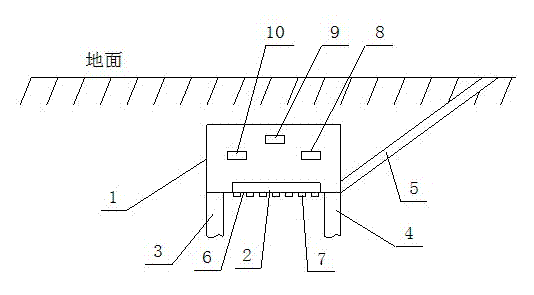

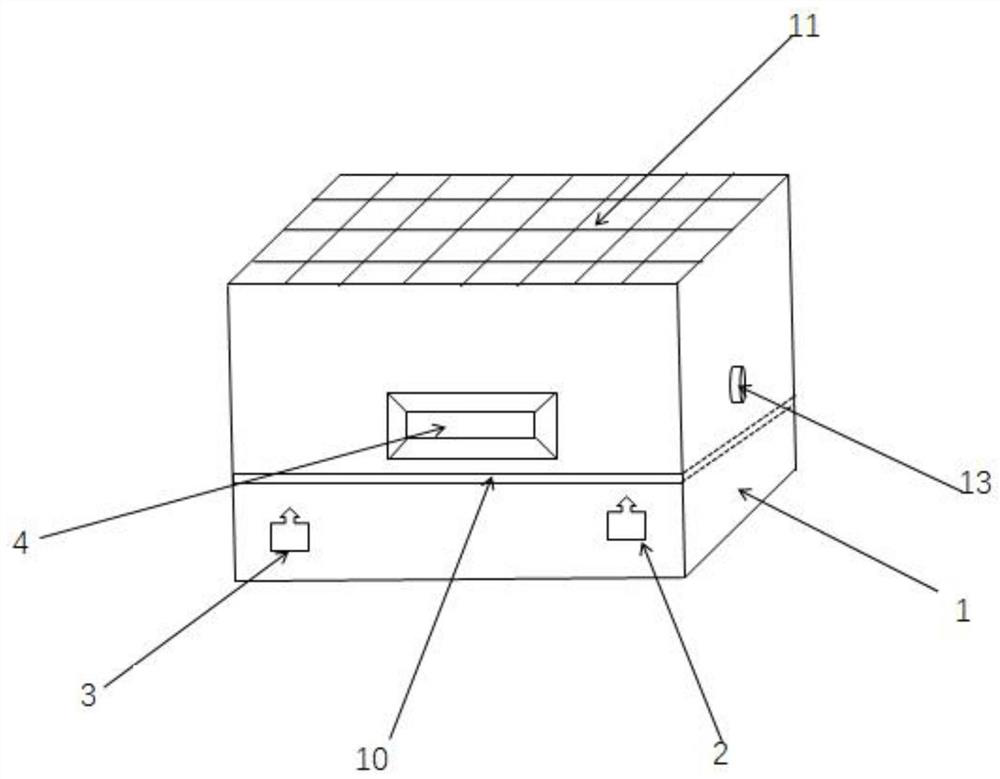

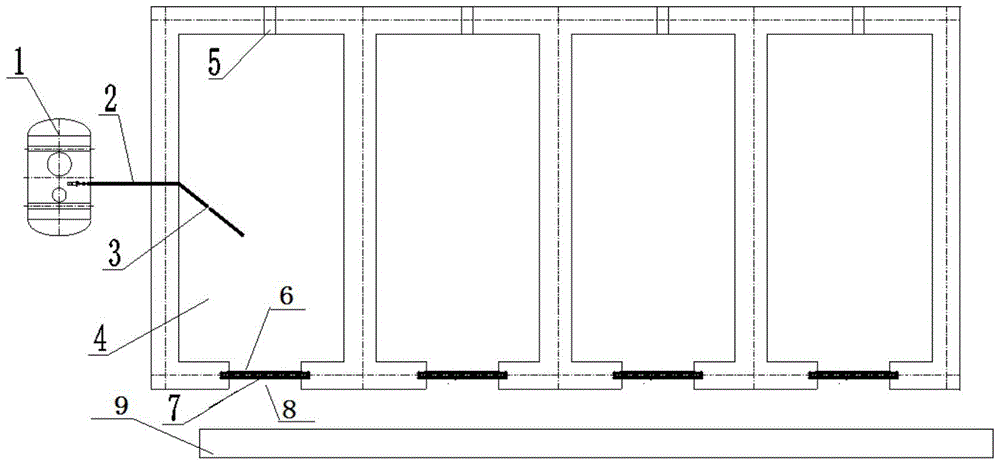

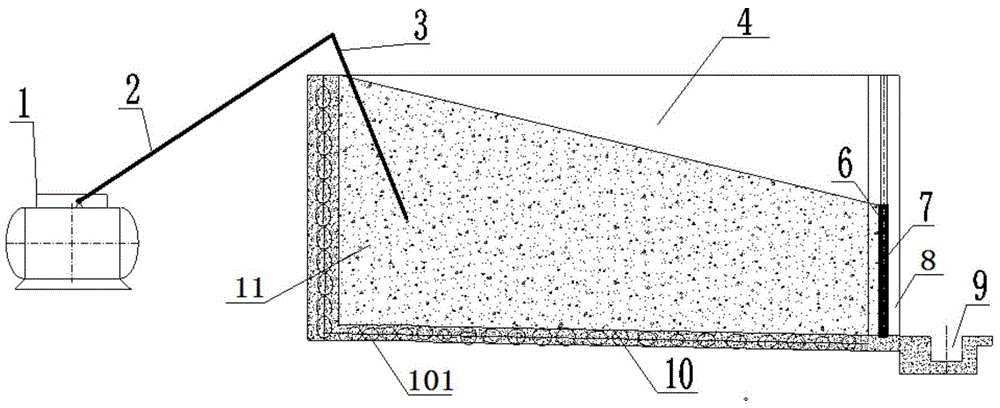

A rapid dehydration system for iron concentrate powder

ActiveCN105056620BLess investment in facilitiesSmall footprintFiltration circuitsSlurryHigh pressure

The invention discloses a rapid dehydration system for iron concentrate powder, which belongs to the technical field of mineral processing in the metallurgical industry. The dehydration system of the present invention includes a sedimentation tank, a filter device, a high-pressure air blowing device, an air blowing pipe and a solar heating device, wherein: the sedimentation tank includes a pulp inlet, a pulp spacer, a sedimentation tank discharge port and a slope bottom of the sedimentation tank The ore pulp inlet is opened on one side of the top of the sedimentation tank, and the ore discharge port of the sedimentation tank is opened at the bottom of the other side wall of the sedimentation tank; the pulp spacer is set inside the discharge port of the sedimentation tank; There is a slope bottom of the sedimentation tank with high inclination on the left and low inclination on the right, and the inclination slope is 1 to 3%; the filter device is installed on the inner side of the pulp spacer; the high-pressure air blowing device blows air to the iron concentrate powder in the sedimentation tank through the air blowing pipe; the solar energy The heating device is set on the top of the sedimentation tank. The invention realizes the purpose of rapid dehydration of iron ore concentrate powder in a sedimentation tank in a small and medium-sized iron ore dressing plant with low investment and low water content in the final product.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Energy-saving and environment-friendly natural fresh-keeping storehouse for fruit and vegetable

InactiveCN102845509BImprove the quality of fresh-keeping storageGood for seasonalityFood processingFruits/vegetable preservation by freezing/coolingMechanical equipmentHorticulture

The invention discloses an energy-saving and environment-friendly natural fresh-keeping storehouse for fruits and vegetables. The fresh-keeping storehouse comprises a fruit and vegetable storage space 3-15 m from the ground surface; and the fruit and vegetable storage space is provided with a fruit and vegetable storage device, a cooling water collecting well and a cooling water recovery well. The fresh-keeping storehouse provided by the invention achieves low temperature, natural constant temperature, natural moisturizing and natural antibacterial effect with no or little rely on mechanical equipment, facilities and industrial energy, improves the storage quality of fruits and vegetables, prolongs the fresh-keeping storage period and is conducive to seasonal, spatial off-season and busy season surplus and deficiency regulation and marketing of fruits and vegetables.

Owner:四川省安岳县柠都柠檬科技开发有限公司

Fast dehydration system for iron ore concentrate powder

ActiveCN105056620ALess investment in facilitiesSmall footprintFiltration circuitsHigh pressureMoisture

The invention discloses a fast dehydration system for iron ore concentrate powder, and belongs to the technical field of ore dressing in the metallurgical industry. The dehydration system comprises a sedimentation tank, a filter device, a high-pressure gas blowing device, a gas blowing tube and a solar heating device, wherein the sedimentation tank comprises an ore pulp feeding hole, an ore pulp partition strip plate, an ore discharge hole of the sedimentation tank and a slope bottom of the sedimentation tank; the ore pulp feeding hole is formed in one side at the top end of the sedimentation tank, and the ore discharge hole of the sedimentation tank is formed in the bottom of the side wall at the other side of the sedimentation tank; the ore pulp partition strip plate is arranged at the inner side of the ore discharge hole of the sedimentation tank; the bottom of the sedimentation tank is the slope bottom, with an inclined angle which is higher at the left side and lower at the right side, of the sedimentation tank, and the gradient of the inclined angle is 1-3%; the filter device is arranged at the inner side of the ore pulp partition strip plate; the high-pressure gas blowing device blows gas to the iron ore concentrate powder in the sedimentation tank by virtue of the gas blowing tube; and the solar heating device is arranged on the top of the sedimentation tank. According to the fast dehydration system, the iron ore concentrate powder of ore dressing plants for small and medium-sized iron ore mines is fast in dehydration in the sedimentation tank; the investment is little; and a final product is low in moisture content.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Method for producing white matte by mixed smelting of multi-source complex low-grade copper ore

ActiveCN104232925BAchieve recyclingLess investment in facilitiesProcess efficiency improvementMass ratioSlag

The invention discloses a method for carrying out mixed melting on multisource complex low-grade copper ores to produce white matte. The method comprises the following steps: carrying out batching according to a mass ratio of copper content of copper concentrates to copper content of scrap copper to copper content of refining slags of copper pyrites of 1:(0.30 to 0.45):(0.002 to 0.006); adding the copper concentrates, the scrap copper and the refining slags of the copper pyrites into a melting furnace; adding anthracite of which mass accounts for 5 percent to 19 percent of the total mass of the copper concentrates, the scrap copper and the refining slags of the copper pyrites into the melting furnace; melting in the oxygen-enriched air to produce the white matte. The method disclosed by the invention has a small investment scale, is low in energy consumption, continuously operates and can implement recycling of copper resources.

Owner:JIYUAN XINXIN INDAL +1

A discharge plasma assisted combustion energy-saving and environment-friendly oven

ActiveCN107928442BAvoid pollutionGreat tasteClimate change adaptationRoasters/grillsCo2 absorptionPollutant emissions

The present invention is an energy-saving and environment-friendly oven with discharge plasma assisted combustion, which comprises an insulating shell and a charcoal chamber. A high-voltage electrode is provided on the side, and a chute is provided between the lifting control device and the insulating shell; the high-voltage electrode inside the charcoal chamber is connected to the control device through a high-voltage wire; the carbon dioxide absorption and fire extinguishing device is connected to the gas inlet and outlet holes. catch. Adjust the voltage to control the charcoal flame, and make the charcoal fully burn in oxygen-poor areas and absorb carbon dioxide; make full use of electric energy, make the fire even, realize smokeless barbecue, make the food rich in active substances, and taste better; and less pollutants emissions, safe and reliable.

Owner:ANHUI UNIV OF SCI & TECH

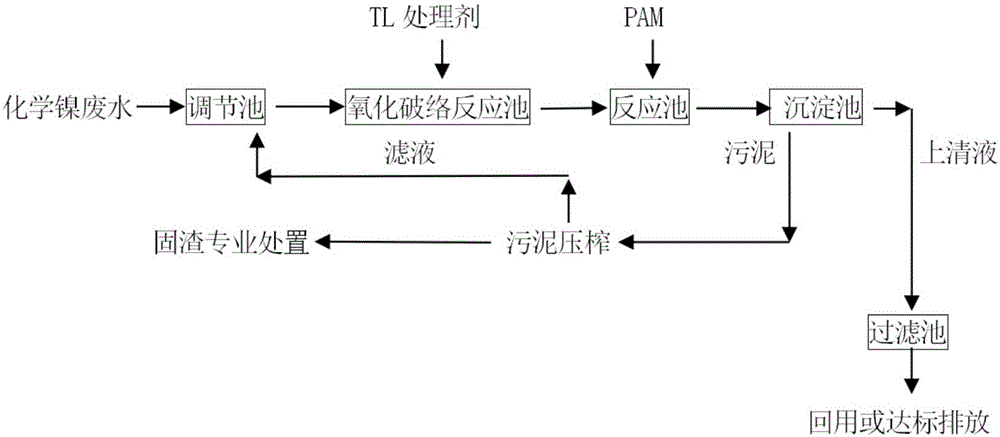

A chemical nickel wastewater treatment agent

ActiveCN105712465BAchieve settlementEasy to makeWater contaminantsWaste water treatment from metallurgical processWastewaterWater quality

The invention provides a chemical nickel wastewater treatment agent which comprises 70-90 wt% of alkaline matter and 10-30 wt% of oxidizer. The chemical nickel wastewater treatment agent is characterized in that the alkaline matter is one or more of NaOH, Na2CO3 and CaO; and the oxidizer is H2O2 or / and Na2S2. The agent is used for treating chemical nickel wastewater and implementing complete and thorough settling of nickel ions and phosphorus; and the water quality completely satisfies the discharge standard in Table 3 in GB21900-2008 Electroplating Pollutant Discharge Standard.

Owner:漆雅丽 +1

Working method of combined wind wave and current resistant net cage

InactiveCN102630613BImprove securityIncrease flow resistanceClimate change adaptationPisciculture and aquariaFiberWind wave

The invention discloses a combined wind wave and current resistant net cage and a working method thereof. The combined wind wave and current resistant net cage comprises a high-density polyethylene (HDPE) integrated framework and net cage bodies, and is characterized in that a plurality of square net cage units are arranged in the integrated framework formed by an HDPE tube; floating rope frames formed by a high-intensity fiber rope are arranged at the peripheries of the square net cage units below each edge of the HDPE integrated framework; a plurality of net cage bodies are arranged in the floating rope frames; and every two adjacent net cage bodies in the same square net cage unit are fixed by a multi-net-cage connector. The combined wind wave and current resistant net cage has excellent wind wave and current resistance, can keep the shapes of the net cage bodies stable and is structurally similar to the conventional fish raft; on the premise that water inside and outside the net cage can be well exchanged, the flowing deformation performance of the net is improved thoroughly; and furthermore, cultivation is convenient to manage; and the facility investment is relatively low.

Owner:FISHERIES RES INST OF FUJIAN

drinking water purification system

ActiveCN106810023BLow costWon't happenTreatment involving filtrationTreatment with aerobic and anaerobic processesLand resourcesPotable water

The invention discloses a drinking water purification system. The drinking water purification system comprises a box body, wherein a treatment area and a clear water area are arranged in the box body; at least part of the box body is arranged in water of a water source; the treatment area comprises a sedimentation pond and a filtering pond; and a water inlet allowing the water source to enter the treatment area is formed in the box body. According to the drinking water purification system, a traditional water taking mode and a traditional water taking source are changed, and water of the water source can spontaneously flow over into the box body to be purified, so that arrangement of a water taking power source is omitted, and the power consumption for long-term running of the water taking power source is reduced; and an overall treatment device is placed in water, so that occupation of land resources is not required, accordingly, lots of land resources are saved, the running cost is lowered and the drinking water purification system is more energy-saving and environment-friendly.

Owner:ZHEJIANG LIANCHI WATER EQUIP

Method for producing white matte by mixed smelting of copper refining slag-pyrite-bornite tailings

The invention discloses a method for producing white matte by mixed smelting of copper refining slags-pyrite-bornite tailings. The method comprises the following steps of: preparing materials according to the mass ratio of the copper contents of the copper refining slags, the pyrite and the bornite tailings being 1:(0.006 to 0.01):(0.02 to 0.09), adding the copper refining slags, the pyrite and the bornite tailings to a smelting furnace, adding anthracite which accounts for 5% to 19% total mass of the copper refining slags, the pyrite and the bornite tailings to the smelting furnace, and smelting in oxygen-enriched air to generate the white matte. The method for producing the white matte by the mixed smelting of the copper refining slags-pyrite-bornite tailings is small-scale in investment, low in energy consumption, continuous in operation and capable of recycling copper resources.

Owner:JIYUAN XINXIN INDAL +1

A method for rapid dehydration of iron concentrate powder in a sedimentation tank

InactiveCN105032030BLess investment in facilitiesSmall footprintFiltration circuitsVolumetric Mass DensityAir compressor

Owner:马鞍山市茂鑫环保新材料有限公司

Potato starch wastewater treatment process

ActiveCN108947116AImprove water qualityLess investment in facilitiesWater contaminantsTreatment involving filtrationWater dischargePotato starch

The invention relates to the technical field of starch wastewater treatment, and particularly relates to a treatment process for potato starch production wastewater. Starch extraction wastewater is pretreated by addition of an acidity regulator, flocculation lumps are formed; and a part of the flocculation lumps is precipitated at the bottom of a flow tank during flowing; the wastewater is naturally placed in a wastewater collection tank for more than 120 days, and then enters a wastewater filter tank for performing filtration treatment; a flocculant is added, precipitation is performed for 2-3 hours after stirring; and the wastewater after flocculation treatment enters an anaerobic system and an aerobic biochemical system in order to further purify the water quality to meet a discharge standard. Objects of the potato starch wastewater treatment process are to solve the problem of wastewater treatment in small and medium-sized potato starch, and to solve the problems of large investment, long start-up period, waste of waste water resources, non-standardized water discharge and high operation cost of sewage treatment equipment in a wastewater treatment process.

Owner:南阳市固德威机械装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com