drinking water purification system

A water purification system and drinking water technology, applied in the field of water treatment, can solve the problems of reducing manufacturing cost, construction cycle, and short manufacturing cycle, and achieve the effects of saving electricity and energy costs, short manufacturing cycle, and saving investment and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

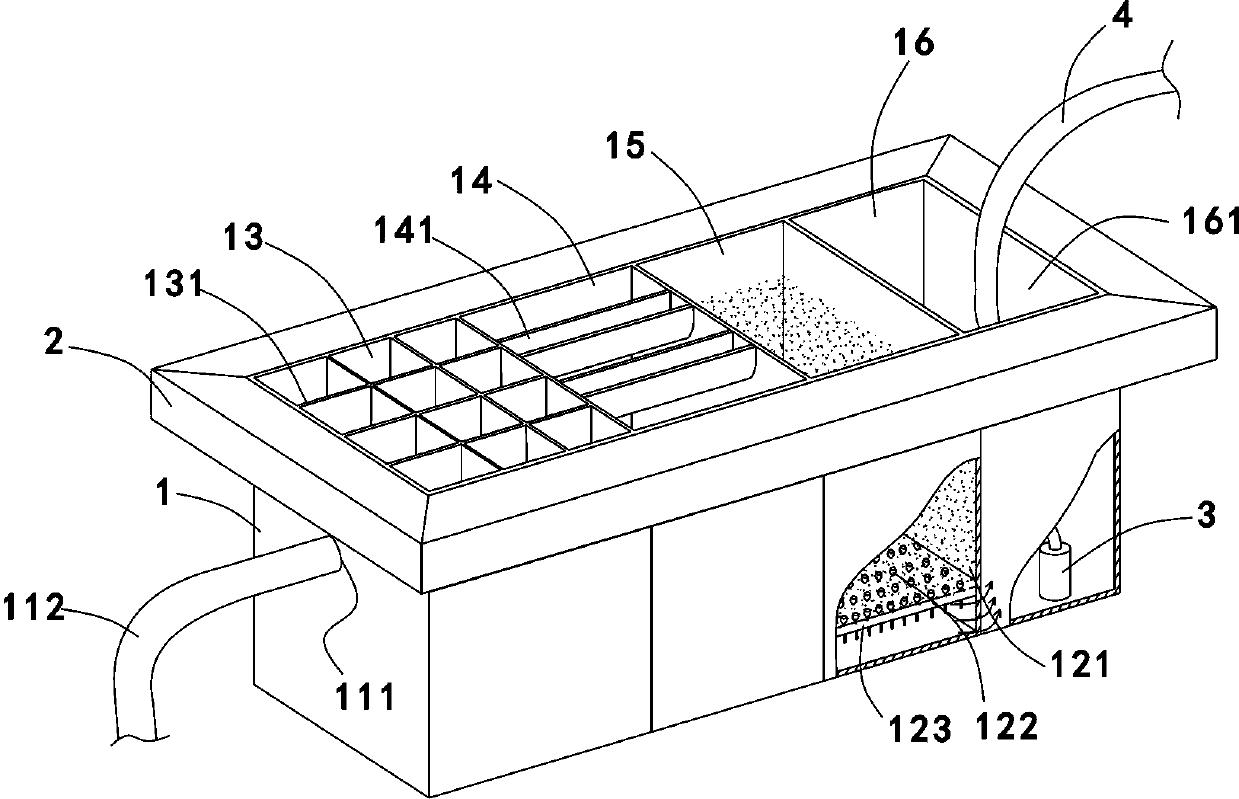

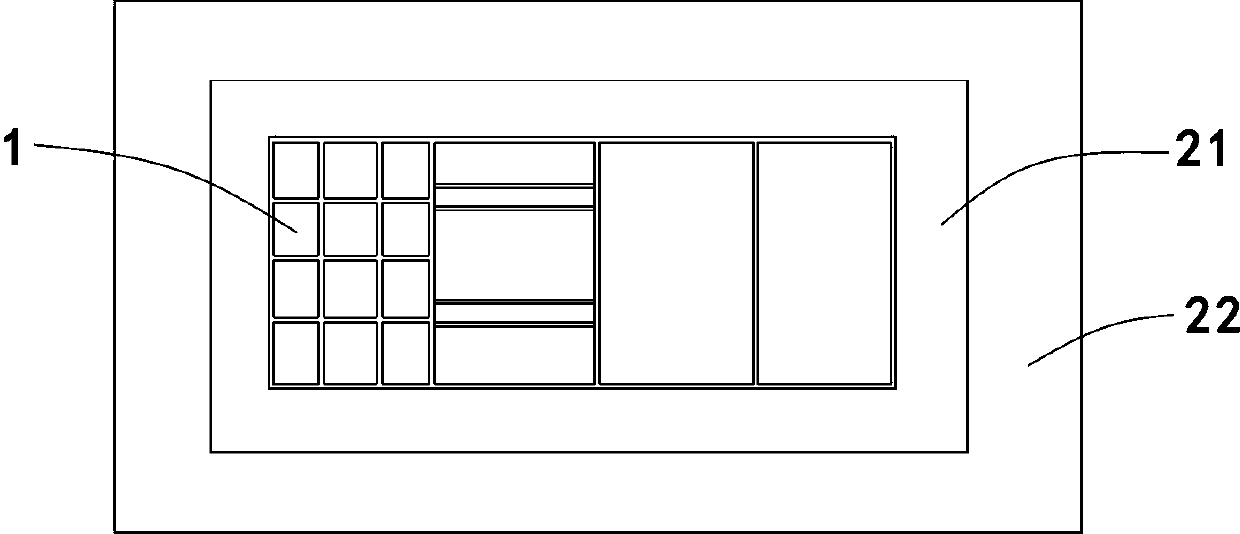

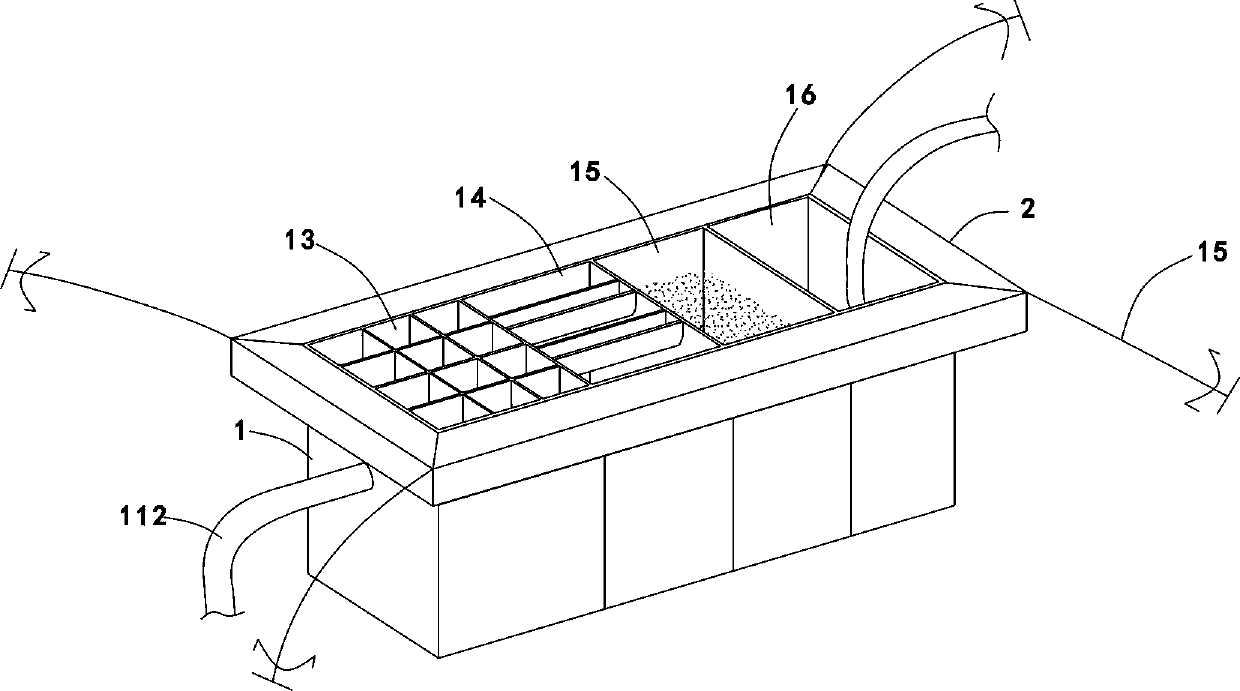

[0024] refer to Figure 1-3 As shown, a drinking water purification system includes a cube or cuboid box 1, the box is at least partly set in the water body of the water source, specifically, the water source includes reservoirs, rivers and lakes, rivers, river courses, lakes And one of the streams, of course, these limitations are not all, the water source can also be other natural or artificial water sources; the above schematic diagram is only for reference, not a specific limitation on the size, the exact size should be based on the actual production size The ratio shall prevail; the box body 1 is made of steel or stainless steel and other metal materials that are not easy to rust after long-term use, which prolongs the service life of the box body. The box body 1 is isolated into four areas, namely the flocculation reaction tank 13, the sedimentation tank 14, the filter tank 15 and the clean water area 16, that is, the treatment area includes the flocculation reaction tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com