Cross-flow type super rotary jetting wind power station

A cross-flow, super technology, applied in wind power generation, wind turbines, wind turbine combinations, etc., can solve the problems of high manufacturing cost, heavy fan head, scattered installation area, etc., to reduce manufacturing cost and difficulty, wind energy utilization The effect of high efficiency and reduced facility investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

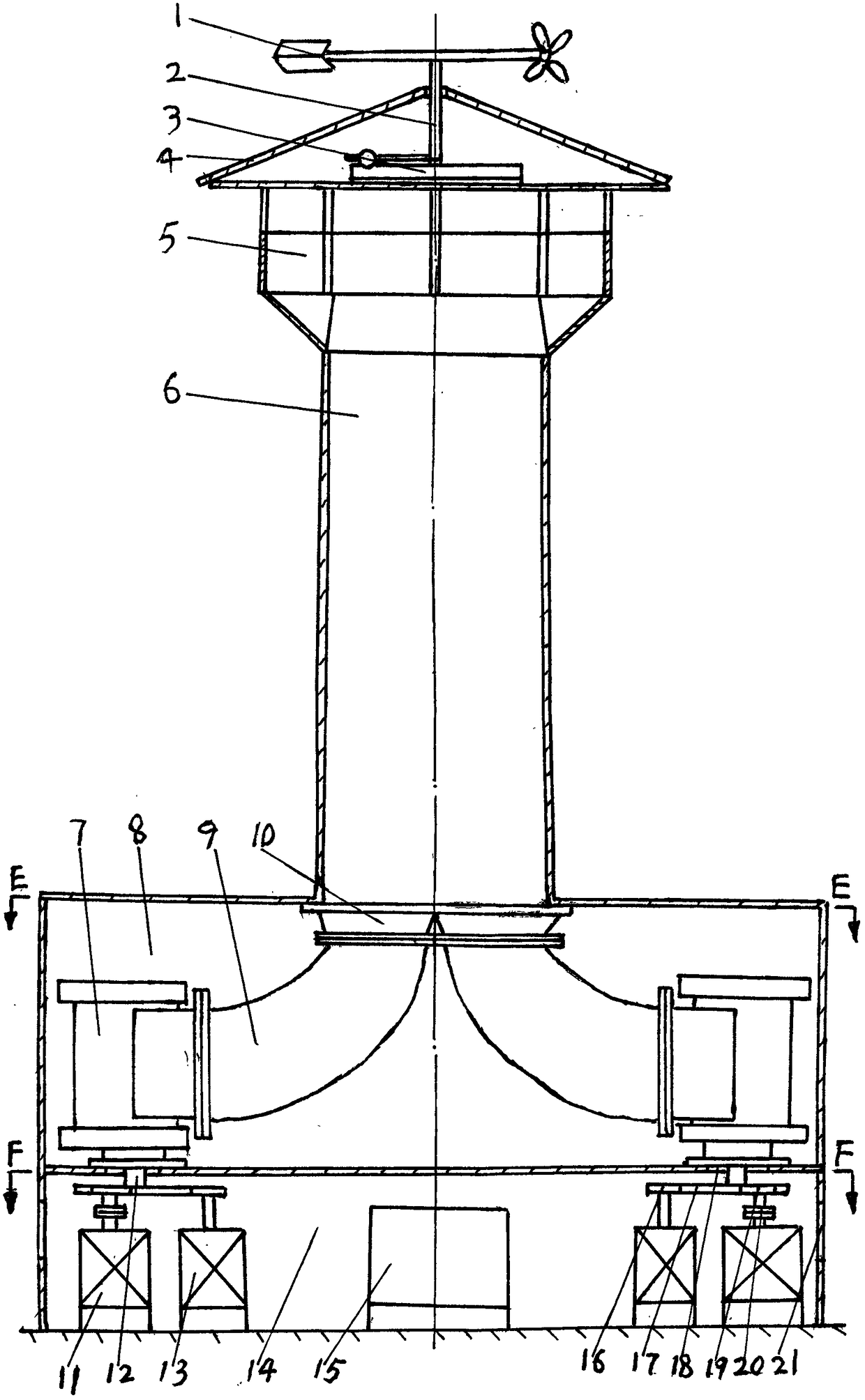

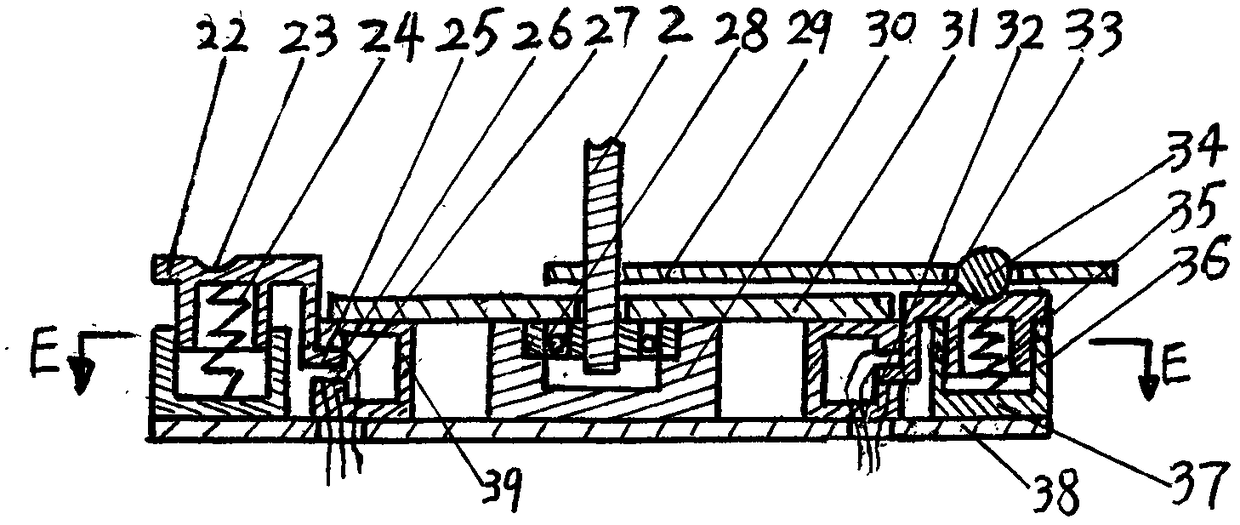

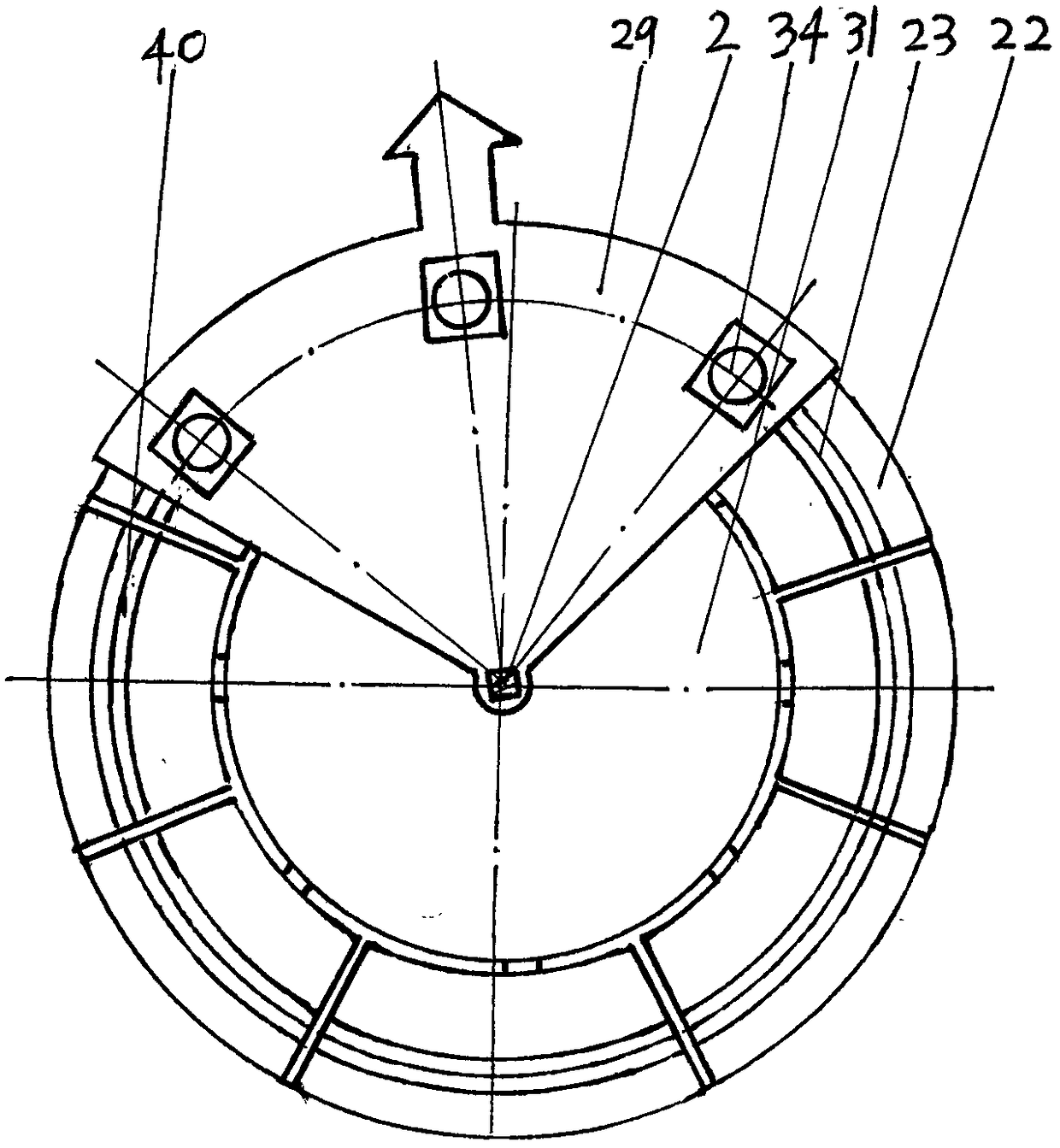

[0039] Such as figure 1 , figure 2 , image 3 As shown, the cross-flow super jet wind power station is composed of related facilities and related equipment. The related equipment includes anemometer 1, main generator 13, mediation generator 11, jet jet machine 7, automatic Wind chasing instrument 4, variable diameter air duct 9, air volume distribution head 10, battery 15, clutch 20, window lifter, etc. Related facilities include rain shelter 4, wind drinking pavilion 5, air induction building 6, power generation room 14. For buildings such as the fan room 8, the power generation room 14 with a number of tail wind discharge windows 21 is located on the bottom of the power generation facility between the surrounding walls. 6. The upper end of the wind-inducing building 6 is fixed with a drinking wind pavilion 5, and the top of the drinking wind pavilion 5 is covered with a conical rain-shielding pavilion 4, and a wind direction indicator 1 is installed on the conical top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com