Method for producing white matte by mixed smelting of copper refining slags-pyrite-bornite tailings

A technology for bornite tailings and copper refining slag is applied in the field of producing white matte copper by mixed smelting of copper refining slag, pyrite and bornite tailings, and can solve the problem of not obtaining widespread promotion and production technology. The problems of high smoke and dust rate and high amount of white matte slag returned can shorten the production cycle, save facility investment and increase labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method of producing white matte by using copper refining slag-pyrite-bornite tailings mixed smelting of the present invention, the components of the copper refining slag, pyrite and bornite tailings used are as follows, The contents all represent the mass fraction of the element:

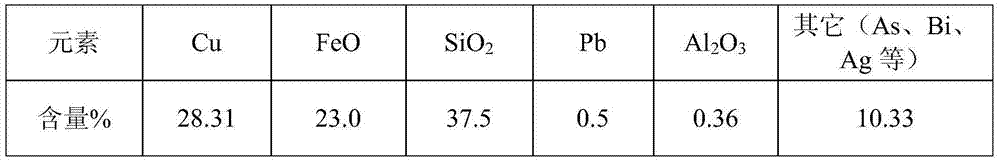

[0032] The composition of copper refining slag is:

[0033]

[0034] The composition of pyrite (the main function of pyrite is to provide FeS) is:

[0035] the element

Fe

S

Cu

other

Content%

40.11

52.37

0.55

6.97

[0036] The composition of bornite tailings is:

[0037] the element

Cu

other

Content%

8.47

91.53

[0038] The composition of anthracite is:

[0039] Element

Volatile matter

Ash

total

Content%

72.33

11.78

15.89

100

[0040] According to the mass ratio of copper content of copper refining slag, copper content of p...

Embodiment 2

[0043] A method for producing white matte by using copper refining slag-pyrite-bornite tailings mixed smelting of the present invention, the components of the copper refining slag, pyrite and bornite tailings used are as follows:

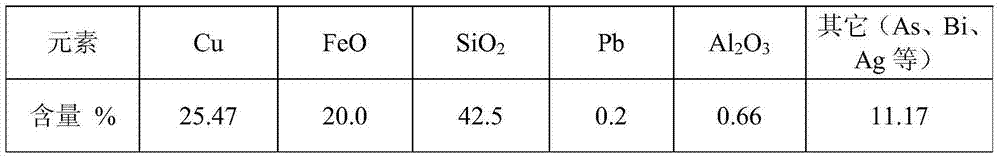

[0044] The composition of copper refining slag is:

[0045]

[0046] The composition of pyrite (the main function of pyrite is to provide FeS) is:

[0047] the element

Fe

S

Cu

other

Content%

44.11

53.31

0.45

2.13

[0048] The composition of bornite tailings is:

[0049] the element

Cu

other

Content%

14.23

85.77

[0050] The composition of anthracite is:

[0051] Element

Volatile matter

Ash

total

Content%

72.33

11.78

15.89

100

[0052] According to the mass ratio of copper content of copper refining slag, copper content of pyrite, copper content of bornite tailings is 1:0.006:0.086, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com